Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

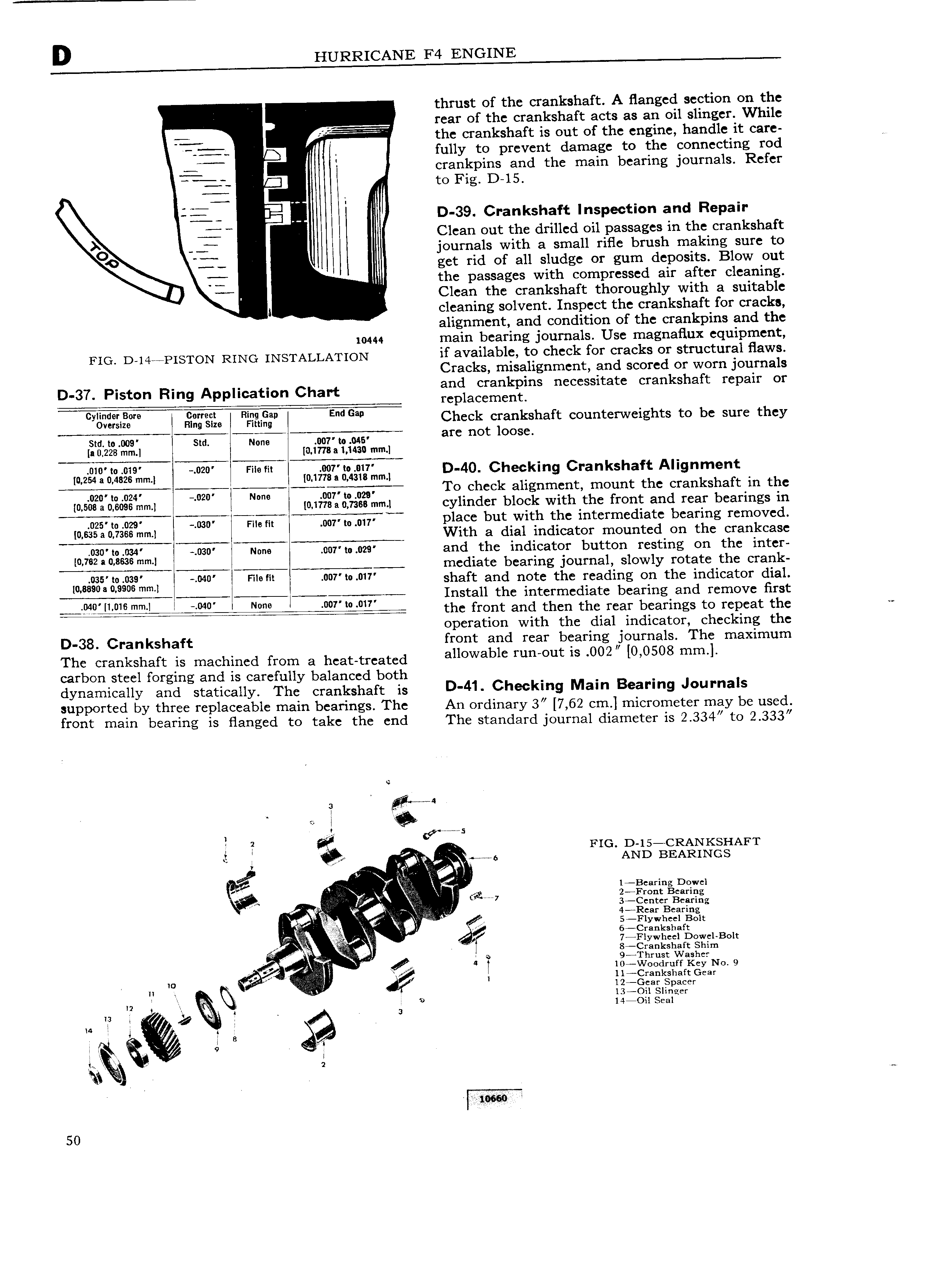

i thrust of the crankshaft A flanged section on the rear of the crankshaft acts as an oil slinger While the crankshaft is out of the engine handle it care I fully to prevent damage to the connecting rod crankpins and the main bearing journals Refer Q to Fig D l5 l F D 39 Crankshaft Ins ectnon and Repair n P Clean out the drilled oil passages in the crankshaft journals with a small rifle brush making sure to get rid of all sludge or gum deposits Blow out the passages with compressed air after cleaning I Clean the crankshaft thoroughly with a suitable I cleaning solvent Inspect the crankshaft for cracks alignment and condition of the crankpins and the 10444 main bearing journals Use magnailux equipment F1G D I4 vI IS I ON RING INSTALLATION if available to check for cracks or structural flaws Cracks misalignment and scored or worn journals D 37 Piston Ring Application Chart and crankpins necessitate crankshaft repair or replacement l g R II l l E l Gall Check crankshaft counterweights to be sure they T r T are not loose iltgfzgagiogi 1 Sm Nm mill i illli mm i 2g 0tg gg9i m i 2 Film mi g7 6 4 87 m i D 40 Checking Crankshaft Alignment To check alignment mount the crankshaft 1n the n s aao c0ss mm I 0 1778n0 736B mm 1 cylinder block with the front and rear bearings in I 25 I m II3I j II 0 7 I m7 place but with the intermediate bearing removed l 635 73 6 mm l With a dial indicator mounted on the crankcase 0s n u2 4 l 020 I Nuns n1 an 0221 and the indicator button resting on the inter l mediate bearing journal slowly rotate the crank wls ggsg sgbgzs lmti 040 i Filcfit l 001 w 1 l haftlia g nots thedreadigg on the nd1Ca C01 cgal i 4F i ii Ti j T i nsta t e in erme 13 e ear1ng an remove rs the front and then the rear bearings to repeat the operation with the dial indicator checking the D 38 Crankshaft front and rear bearing Ijournals The maximum The crankshaft is machined from a heat treated allowable lullout ls 002 0 0508 mm l carbon steel forging and is carefully balanced both dynamically and statically The crankshaft is D 41 ch km9 Mam Bearmg J u al supported by three replaceable main bearings The An ordinary 3 7 62 cm micrometer may be used front main bearing is flanged to take the end The standard journal diameter is 2 334 to 2 333 l V g 4 1 ll fl ifowld I f 7 FIG D 15 cRANKsHAFT Q fs V I M6 AND BEARINGS I A 1 earin Dowel ll t g fl I v I A Z Z i3 Z i g Sag nn 5ipi3L1 c2ili t E E v v I l 6 Crankshaft I 7 Flywheel Dowel B0lt I i Ei I 2 8 hs 2 l A gi l0 Wv f 1 lruffllgeyANo 9 10 4 I I if y i grar1k haft Gear I if lb T ia i I 3 14701 ea l s e 8 Q Q 50

Next

Next