Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

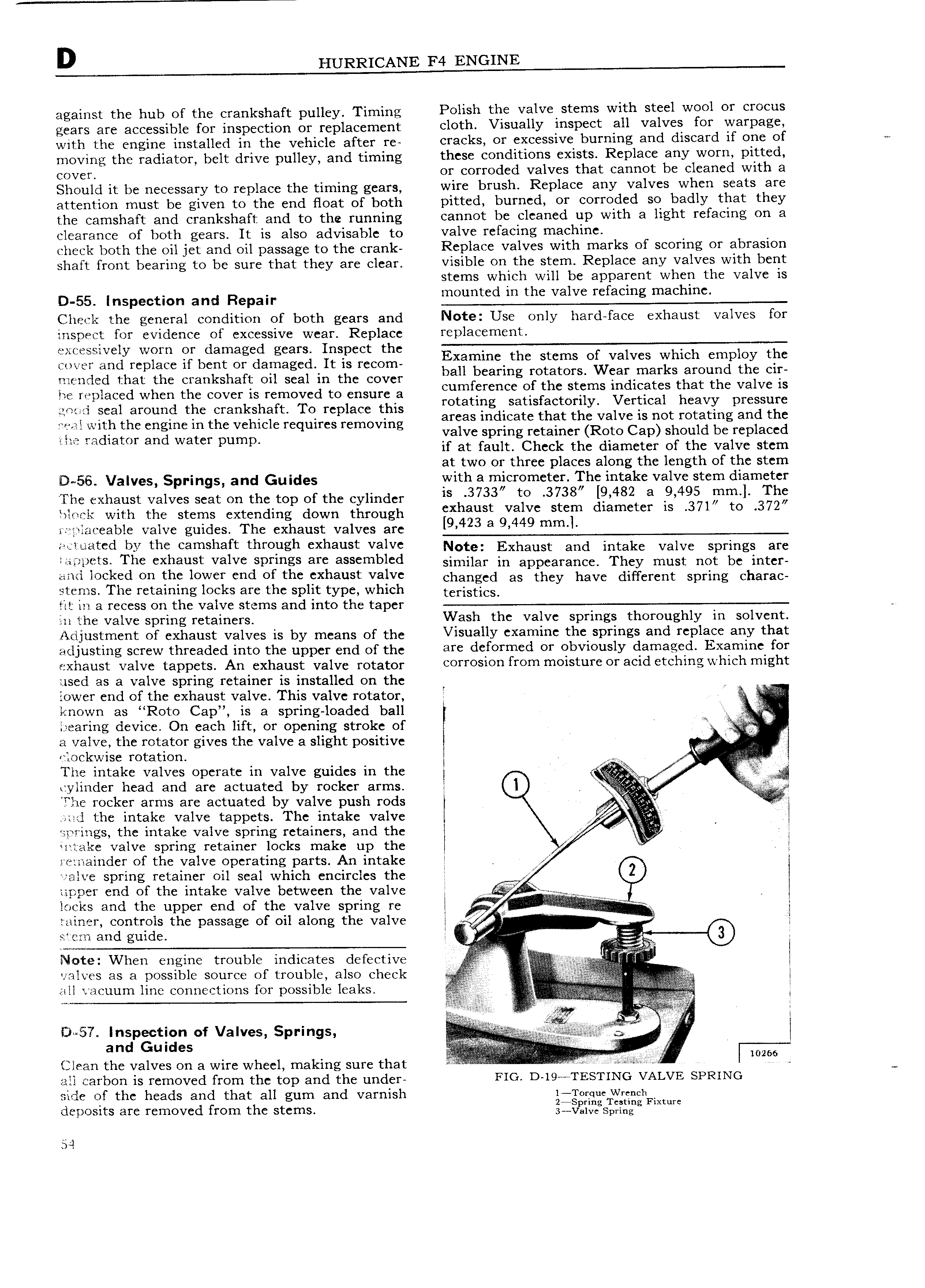

against the hub of the crankshaft pulley Timing Polish the valvelstems with steel wool or crocus gears are accessible for inspection or replacement l0th Vlsu llly P t all valves for YVQYPHEQ with the engine installed in the vehicle after rc f3Cl S OY S lV bummg and discard lf OP Of W moving the radiator belt drive pulley and timing these cogd tions exislts Replace lanylworn pitttled cover or corro e va ves t at cannot e c eane wi a Should it be necessary to replace the timing gears wire brush Replace any valves when seats are attention must be given to the end float of both pitted burned or corroded so badly that they the camshaft and crankshaft and to the running cannot be cleaned up with a light refacing on a clearance of both gears It is also advisable to valve 1 l3 1 g m3 h1 check both the oil jet and oil passage to the crank Replace valves with marks of scoring or abrasion shaft front bearing to be sure that they are clear visible ogtlge sting Replace any lyalve withl bent stems w ic wi e apparent w en t e va ve is D 55 Inspection and Repair mounted in the valve refacing machine Check the general condition of both gears and Note USB only h lfd 1 3C Xh3US valves ff inspect for evidence of excessive wear Replace replacement excessively worn or damaged gears Inspect the Examine the Stems of valves which employ the tower and replace if bent or damaged It is recom W k d th mended that the crankshaft oil seal in the cover ball bearing mtatOrs gm mar S amun C C1 he 1 d hen the Cover is removed to Cn r 3 cumference of the stems indicates that the valve is C r p acc W Su C tatin satisfactoril Vertical heavy pressure gmx seal around the crankshaft To replace this FO g y d h real with the engine in the vehicle requires removing areas Indicate thllt the Valve ls not mtatmg anl t 5 me me pump L rZ 1 g Eii i1 ER rZ I EZ EHS 255 2 at two or three places along the length of the stem 55 Valves Springs and Guides with a rrricrometer The intake valve stem diameter The exhaust valves seat on the top of the cylinder ls 3733 ts 3738 9 482 3 9 495 1m l Th fvlrick with the stems extending down through cxhaust Valvc stem diameter ls 371 to 372 l i l T 3l l valve guides The exhaust valves are 9 423 a 9 449 mm l mtaated by the camshaft through exhaust valve Note Exhaust ahd intake Valve Springs are zaqipets The exhaust valve springs are assembled Similar gh appcaranCc They must ngt be rarer ami locked on the lower end of the exhaust valve Changed as they have different spring oharao stems The retaining locks are the split type which teristgeeh tit in a recess on the valve stems and into the taper in the valve spring retainers 35 V8 VC Pl l g OYOUE Y lll 0 VCH Adjustment of exhaust valves is by means of the Visually examine tll PYl g and fcplagc QYQY that adjusting screw threaded into the upper end of the 3F d f rm d OT 0bVl0u lY d m3 d l X3mm for exhaust Valve tappgtg An gxhaust valve rotator corrosion from moisture or acid etching which might used as a valve spring retainer is installed on the A iower end of the exhaust valve This valve rotator i known as Roto Cap is a spring loaded ball hearing device On each lift or opening stroke of V a valve the rotator gives the valve a slight positive I P l 4 clockwise rotation E er The intake valves operate in valve guides in the I cylinder head and are actuated by rocker arms 4 i 6 The rocker arms are actuated by valve push rods A l nd the intake valve tappets The intake valve l smixigs the intake valve spring retainers and the t i intake valve spring retainer locks make up the i rcezrlainder of the valve operating parts An intake j i valve spring retainer oil seal which encircles the I zipper end of the intake valve between the valve s a 1 locks and the upper end of the valve spring re l R Q miner controls the passage of oil along the valve r l R 2 s c n and guide i iz l a r r 9 Note When engine trouble indicates defective rl Q rQ l all vacuum line connections for possible leaks E I ii i l t t ous Inspection of Valves Springs c l l and Guides z r Y l i i Clean the valves on a wire wheel making sure that was t if all carbon is removed from the top and the under l lG D l9W l E l lNG VALVE Sl RlNG side of the heads and that all gum and varnish 1 T r Wrencly deposits are removed from the stems giizgiiiigsiisiiaang Fixture 5 4

Next

Next