Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

1115112

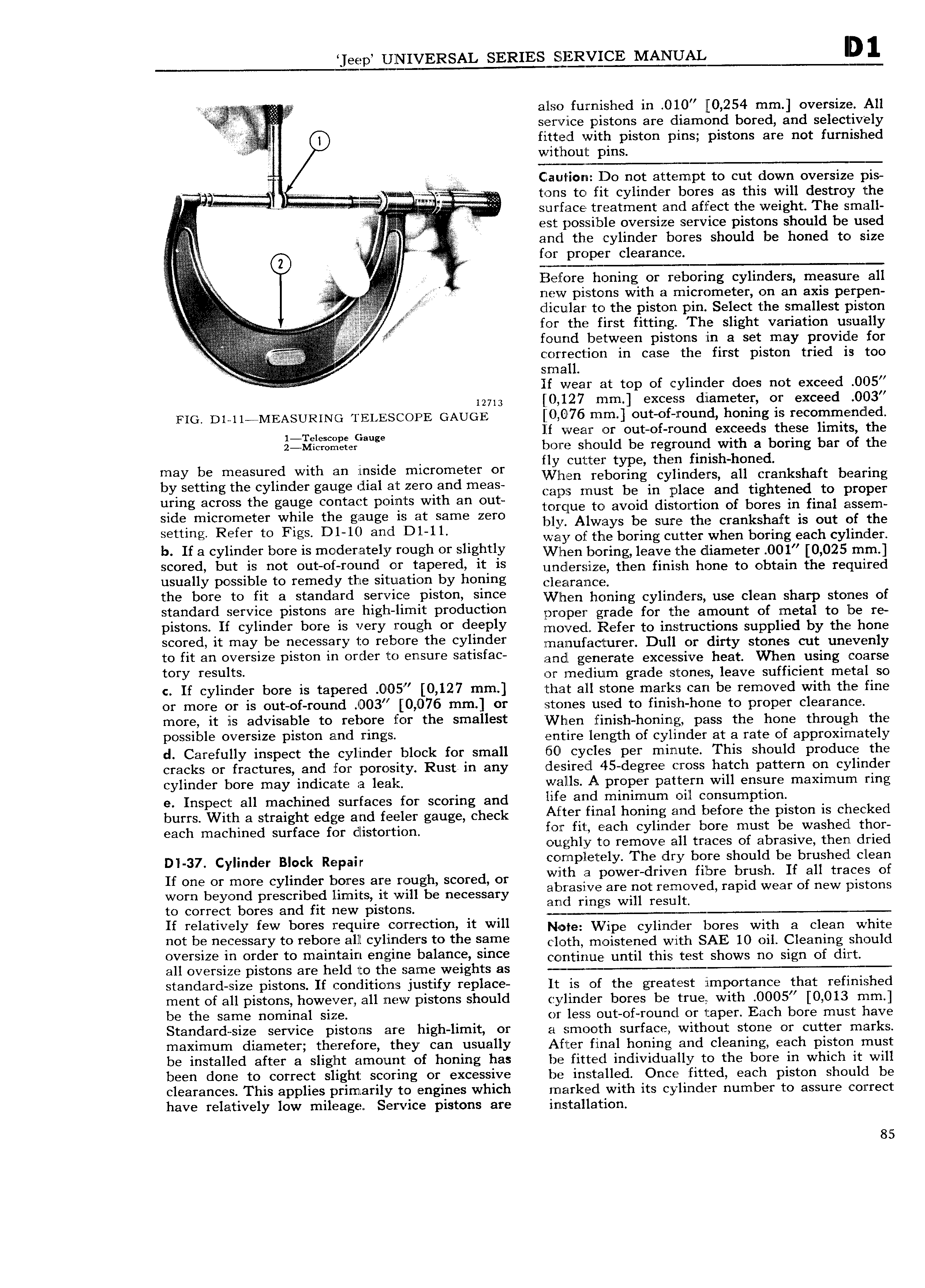

eep UNIVERSAL SERIESEQQQEXECE MANUA E also furnished in 0 0 0 254 mm oversize All 1 service pistons are diamond bored and selectively 0 fitted with piston pins pistons are not furnished without pins Clautionz Do not attempt to cut down oversize pis e 3 i V egg tons to fit cylinder bores as this will destroy the P i V i surface treatment and affect the weight The small V V j Y no est possible oversize service pistons should be used t and the cylinder bores should be honed to size I V il E for proper clearance WD Before honing or reboring cylinders measure all new pistons with a micrometer on an axis perpen dicular to the piston pin Select the smallest piston V V y V p i for the first fitting I he slight variation usually j E f found between pistons in a set may provide for i V correction in case the first piston tried is too i e i srnall i i i ii lf wear at top of cylinder does not exceed 005 1271 127 mm excess diameter or exceed 003 FIG D1 11YMEAsUR1NG r121 1a sco1 E GAUGE 0 0l76 mm out of round honing is recornniended 1 T leSc0pe Gauge lf wear or out of round exceeds these limits the 2 micrometer bore should be reground with a boring bar of the h I 1 fly cutter type then finish honed g18 t1 11 S 11 5 dl 1t al I t i 1 E r 3 1 VV1hen reboringi cylinders all lcrankshaft bearing uiing acriss tn gangegeetiaet pennts with an out 8l be m p1 and sh d t p torque to avoid distortion of bores in final assem S1d mmmmeter w1i111 the g E1ug 1s at same zero bly Always be sure the crankshaft is out of the Settmg Refer to F1gS D1 1O and D1 1 1 way of the boring cutter when boring each cyl inder b If cglinder bore isgngdsrtatglzsr wish M glislztiy Wlnen boring leave the diameter 001 0 025 nnn score y ut is not on o Y onn or oPol o i 1 ls undlersizce then finish hone to obtain the rec uired usually possible to remedy the situation by honing clemencei 1 tho bore to at s standard scY 1 cc P1ston slncc When honing cylinders use clean sharp stones of scandord soYV1c Pistons sro inlgndlmlt Production proper grade for the amount of metal to lbe re Plstonsglf cYnndcY bore is VcYY rough or dccply moved Refer to instructions supplied by the hone sco id It moY be notcossocy tr r ig l r thc cY lnfdcY rnanufacturer Dull or dirty stones cut unevenly to I on ovofslzo Pls on ln ono o cnslno so is ac and generate excessive heat VVhen using coarse tory 1 osn ts or medium grade stones leave sufficient metal so c If cylinder bore is tapered 005 0 127 mm that all stone marks can be removed with the fine or more or is out of round J003 0 076 mm or stones used to finish hone to proper clearance more it is advisable to rebore for the smallest Wh finiSh h0nj g pass the hom through the possible Oversize piston and 1 i1 lgS entire length of cylinder at a rate of approximately d Carefully inspect the cylinder block for small 60 cycles per minute This should produce the cracks or fractures and for porosity Rust in any desired 45 degree cross hatch pat1 ern on cylinder cylinder bore may indicate a leak walls A proper pattern will ensure maximum ring 9 Inspect all machined surfaces for scoring and lifj 10 ml 11 1 1 Oil C OHSumpli10fl bume With 3 Straight edge and feeler gauge Check Atter final honing and before the piston is checked each machined Surface fe e iSte eti m for fit each cylinder bore must be washed thor oughly to remove all traces of abrasive then dried D 3y Cylinder Block Repair completely The jdrjy bore should be brushed clean If one or more cylinder bores are rough scored or WH 11 pOW 1 d1 1V 11 1115112 blush If 11 wages of worn beyond prescribed limits it will be necessary ab1aS1 V 3 a1 t 1Em O V d P d wear O new l S S to correct bores and fit new pistons If relatively few bores require correction it will Nme Wripe cylmdel bores with 3 clean wrhite not be nocosssYY to rebate all cyhnclclis to thc Snmc cloth moistened with SAE 10 oil Cleaning should oVcl slZc in ofdoc to main ton onfimc baloncc smcc continue until this test shows no sign of dirt all oversize pistons are held to the same weights as standard size pistons If conditions justify replace lt is of the greatest importance that refinished ment of all pistons however all new pistons should cylinder bores be true with 0005 0 013 mm be the same nominal size or less out of round or taper Each bore must have Standard size service pistons are high limit or a smooth surface without stone or cutter marks maximum diameter therefore they can usually After final honing and cleaning each piston must be installed after a slight amount of honing has be fitted individually to the bore in which it will been done to correct slight scoring or excessive be installed Once fitted each piston should be clearances This applies primarily to engines which marked with its cylinder number to assure correct have relatively low mileage Service pistons are installation 85

Next

Next