Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

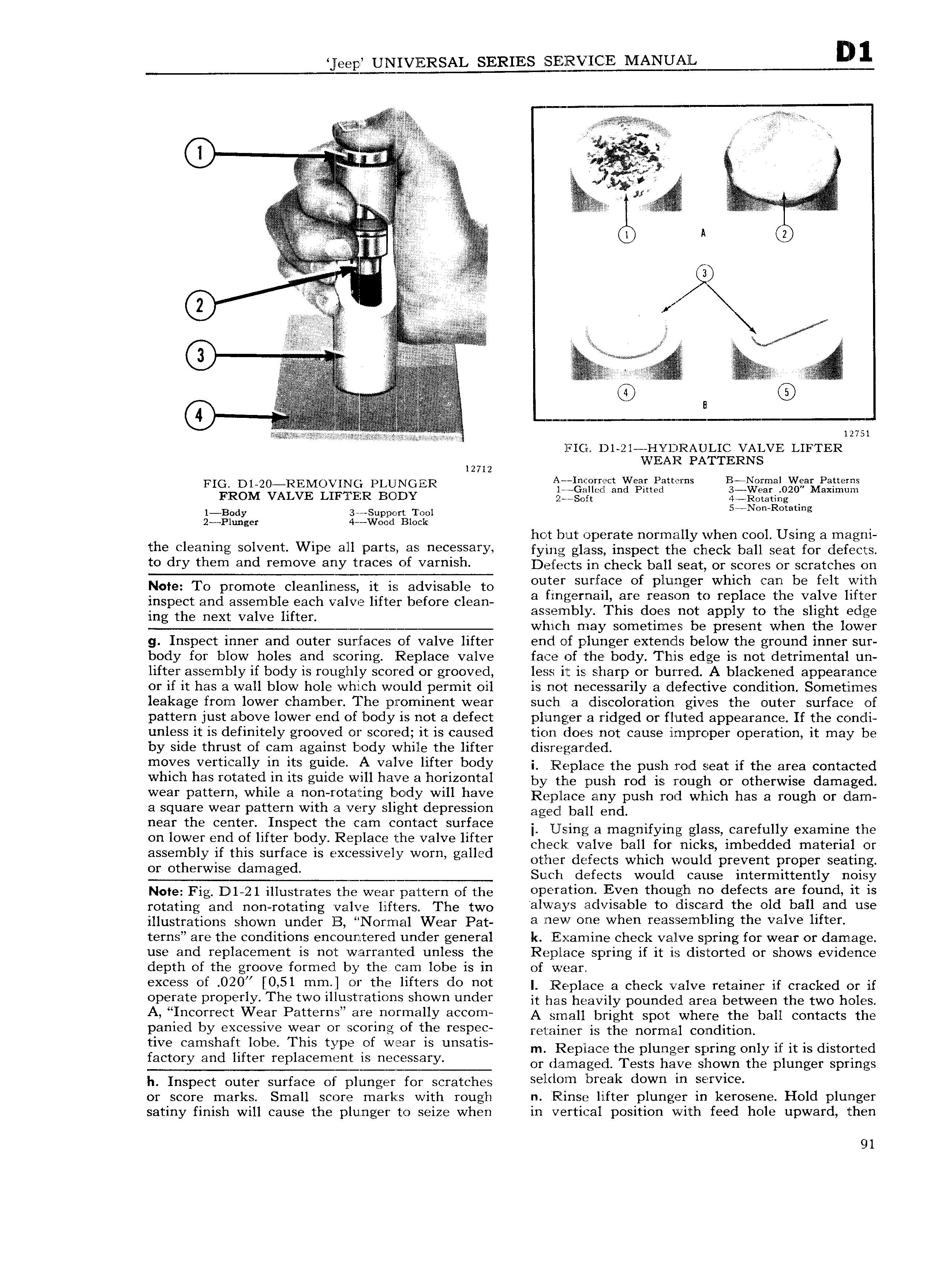

leep UNIVERSAL SERIES MANUAIL iI V oo r it 5 4k n jay o ii r V i wi r i I ii ii lf Z E V Jf V A vV 7 Ei i i i A v 2 i lil wi 9 3 4rV V fp E he 3 ry V A p A Vi s 0 2 E IE XW A V ll IGr Dl 2l I IYKQRAULIC VALVE LIFTER 12712 WEAR PATTERNS FIG DI 20 RE1 IOyrIrJ PLUNGER A Inj orrect Wear Patterns B Normal Wear Patterns FRoM VALVE LIFTER Horny gi1 g2f l rd P 1 Qr f M 1 Body 3 Suppo rt Tool SRRNOH Rotating 2 PIluuger 4 Wood Block I hot but operate normally when cool Using a magni th OIOQOIOEL Solvent WIPO all P3Yl 35 O 3Yy fying glass inspect the check ball seat for defects IO dry th m and 1 mOV any traces Of varmsh Defects in check ball seat or scores or scratches on Noro To ororooro oroooroooo rr is advisable to g QSl fjF Of P lg g r Whljh we be et gyth inspect and assemble each valve lifter before clean 8 l l j T f hSr dr l m to re ace tg V is lgm mg the me me ati Jo 2 SES Q TF Y Hf iifr ge w in 1 y s e el e ese I w e wer g Inspect inner and outer surfaces of valve lifter end of plunger extends below the ground inner sur body for blow holes and scoring Replace valve face of the body This edge is not detrimental un lifter assembly if body is roughly scored or grooved less it is sharp or burred A blackened appearance or if it has a wall blow hole which would permit oil is not necessarily a defective condition Sometimes leakage from lower chamber The prominent wear such a discoloration gives the outer surface of pattern just above lower end of body is not a defect plunger a ridged or fluted appearance If the condi unless it is definitely grooved or scored it is caused tion does not cause improper operation it may be by side thrust of cam against body while the lifter disregarded mvves v r a11y m its guide A valve hfrer body a jreeepioee the push rod seat rr the area contacted which has rotated in its gu1d e will have a horizontal by tilde hugh red is rough Or Otherwise dama ged WOW Patterlk while 3 OOO Y Ot 3lU g OOOY will have Replace any push rod which has a rough or Clam a square wear pattern with a very slight depression aged ball ehd near the center U Inspect the cam contact surface i Using 3 magnifying glass carefully examine the on lower end of lifter body Replace the valve lifter Check Vnlve ball for niCkS nmbedd d material Or gisggibiy gf fl Surfaf S X S y m gaurd other dereots whreh would preverrr proper seating 9 W SE amage Such defects would cause intermittently noisy Note Fig D l 2l illustrates the wear pattern of the OPOYBUOU Even thOul 1fl OO defects are f u d it is rotating and rrorrrotatrrrg valve hfr erS The WO always advisable to discard the old ball and use illustrations Shown under 3 NOr ma Wear pat a new one when reassembling the valve lifter terns are the conditions encountered under general k EZ r an 1ine check valve spring for wear or damage use and replacement is not warranted unless the Replace spring if it is distorted or shows evidence depth of the groove formed by the cam lobe is in of wear OXCOSS of 020 0 51 O tht lifters do not I Replace a check valve retainer if cracked or if OP i 3t PYOl Yly The IWO lllQ t V3UO US Slwwn under it has heavily pounded area between the two holes A l OOYY t W Y Patwmsi 3I UOYm uy 3C Om A small bright spot where the ball contacts the RQOIOO by OXCOSSIVO WO OI SCOUOQQ Of the YOSPOO retainer is the normal condition ENE CamS a f1Ob ilghls type gf ll 3r 1S unS3t1S m Replace the plunger spring only if it is distorted actory an 1 ter rep 3C m f S nfff my or damaged Tests have shown the plunger springs h Inspect outer surface of plunger for scratches l lOm t k OOWU ln Service or score marks Small score marks with rough n Rlinse lifter plunger in kerosene Hold plunger satiny finish will cause the plu nger to seize when in vertical position with feed hole upward then 91

Next

Next