Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

994757

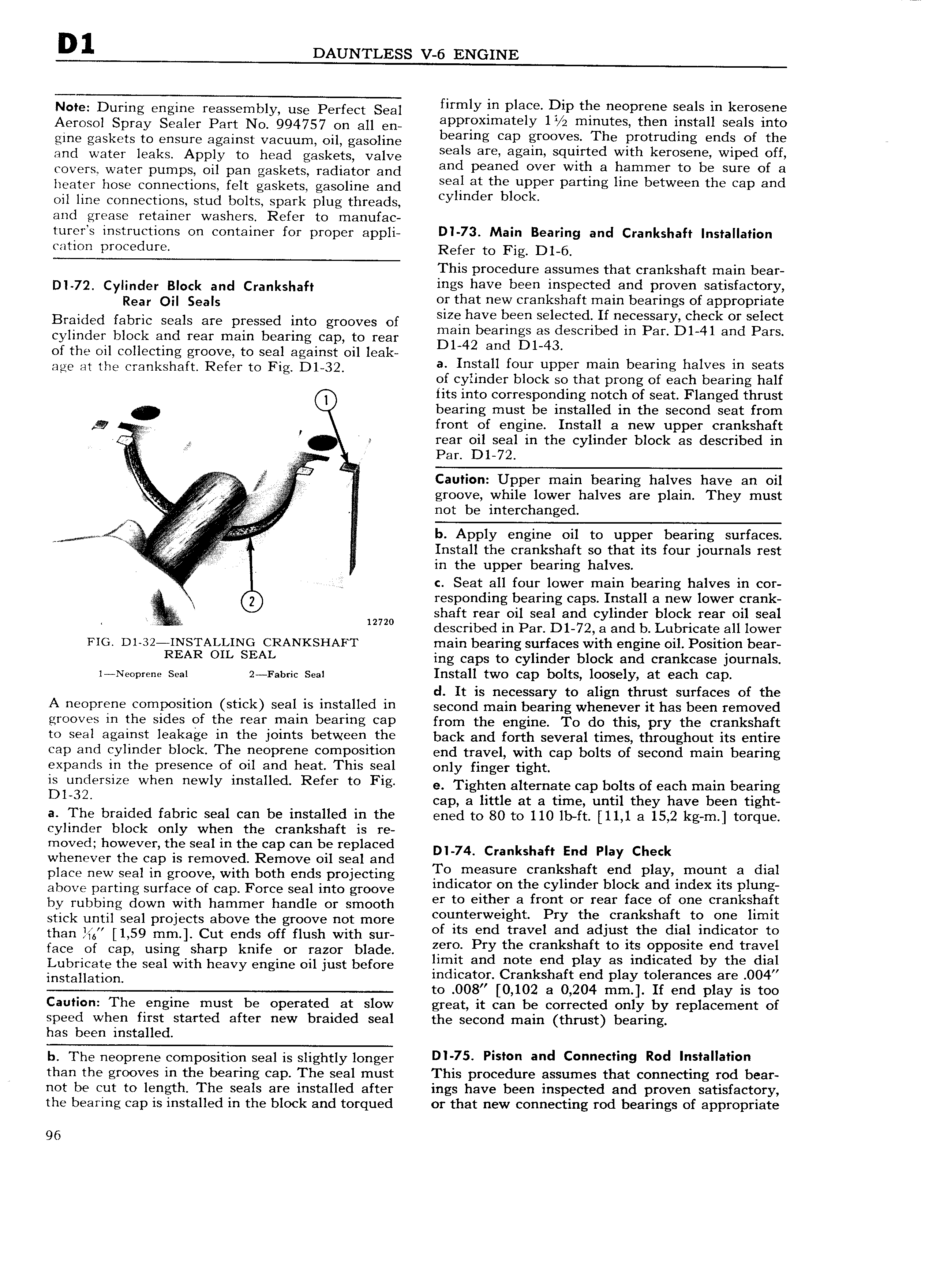

D1 DAUNTLESS V 6 ENGINE Nee During engine eeessemeiy use Perfect Seal firriiiy irr eieee Pie the rierirrrerie eerie irr irereeerie Aerosol Spray Sealer pea Ne 994757 on all ee eeereirirriefeiy ie rrii iireS ffieri i riSieii eeeie irrfe gine gaskets to ensure against vacuum oil gasoline bearing Cap gmoveg The P d g Qndf ef the and Water 1 akS Apply to h 3d gaskets Valve seals are again squirted with kerosene wiped off covers water pumps oil pan gaskets radiator and and peaned ever wld 8 hammer fe be Sure ef 3 heater hose connections felt gaskets gasoline and Seal ef the upper eerririe Img between the Cap and oil line connections stud bolts spark plug threads Cylmder block and grease retainer washers Refer to manufac turer s instructions on container for proper appli DI 73 Main Bearing and Crankshaft Installation cation procedure Refer to Fig D1 6 This procedure assumes that crankshaft main bear D y2 Cyjgndgr Block and Crankshaft ings have been inspectedand proven satisfactory Rea Oil Seals or that new crankshaft main bearings of appropriate B d d f b 1 d size have been selected If necessary check or select rai e a ric seas are presse into grooves of main bearings as described in Par D1 41 and Pars cylinder block and rear main bearing cap to rear DL42 and DL43 of the oil collecting groove to seal against oil leak age Ht me Crankshaft Refgr to Fig D1 32 a Install four upper mam bearing halves in seats of cylinder block so that prong of each bearing half fits into corresponding notch of seat Flanged thrust bearing must be installed in the second seat from gg g r front of engine Install a new upper cranksgaft rear oil seal in the cylinder block as describe in Par D1 72 r Caution Upper main bearing halves have an oil groove while lower halves are plain They must A f i not be interchanged MM W Appl enginlf hog to Lipper Fearing sugfaces I nsta l t e cran s a t so t at its our journa s rest i iii in the upper bearing halves e c Seat all four lower main bearing halves in cor 6 responding bearing caps Install a new lower crank 7 eee se7e9 3 2 es 2 y S iZ1 k Tia ii sm escri in ar aan u rica ea ower FIG D1 32 INSTALLING CRANKSHAFT main bearing surfaces with engine oil Position bear REAR OIL SEAL ing caps to cylinder block and crankcase journals 1 Neoprene Seal ztreimc seei Install two cap bolts loosely at each cap cl It is necessary to align thrust surfaces of the A 0Df 0mP0 iti0 Stick 931 is installed ifi second main bearing whenever it has been removed grooves in the sides of the rear main bearing cap from the engine TO do this pry the crankshaft to seal against leakage in the joints between the back and forth several times throughout its entire Cap and Cyiindef bl0 k The 0P1 0mP0Siti0 end travel with cap bolts of second main bearing expands in the presence of oil and heat This seal Only finger tight ie riririereize Wfierr riewiy rriefeiied Refer fe Fig e Tighten alternate cap bolts of each mein bearing DL32 cap a little at a time until they have been tight a The braided fabric seal can be installed in the ened to 80 to 110 lb ft 11 1 a 15 2 kg m torque cylinder block only when the crankshaft is re moved however the seal in the cap can be replaced DL74 Crankshaft End Play Check whenever the cap is removed Remove oil seal and place new seal in groove with both ends projecting Te measure crankshaft end playf momlt a dial akmvg parting Surface Of Cap Force Seal into groove indicator on the cylinder block and index its plung by rubbing down with hammer handle Or Smooth er to either a front or rear face of one crankshaft stick until seal projects above the groove not more coklnterwelghh PTY the cx ankshaff tc 0 ne limit than mn 1 59 mm Cut ends Off flush with sup of its end travel and adjust the dial indicator to face of cap using sharp knife or razor blade ger pry fhe crankshaft to its Qpposlte end traliel Lubricate the seal with heavy engine oil just before gsggkiggftp ii gigngxgfggcggaigeocggi to OO8 0 102 a 0 204 mm If end play is too Caution The engine must be operated at slow great it can be corrected only by replacement of speed when first started after new braided seal the second main thrust bearing has been installed b The neoprene composition seal is slightly longer 0 75 Pi l and C m i 9 Red I a a i than the grooves in the bearing cap The seal must This procedure assumes that connecting rod bear not be cut to length The seals are installed after ings have been inspected and proven satisfactory the bearing cap is installed in the block and torqued or that new connecting rod bearings of appropriate 96

Next

Next