Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

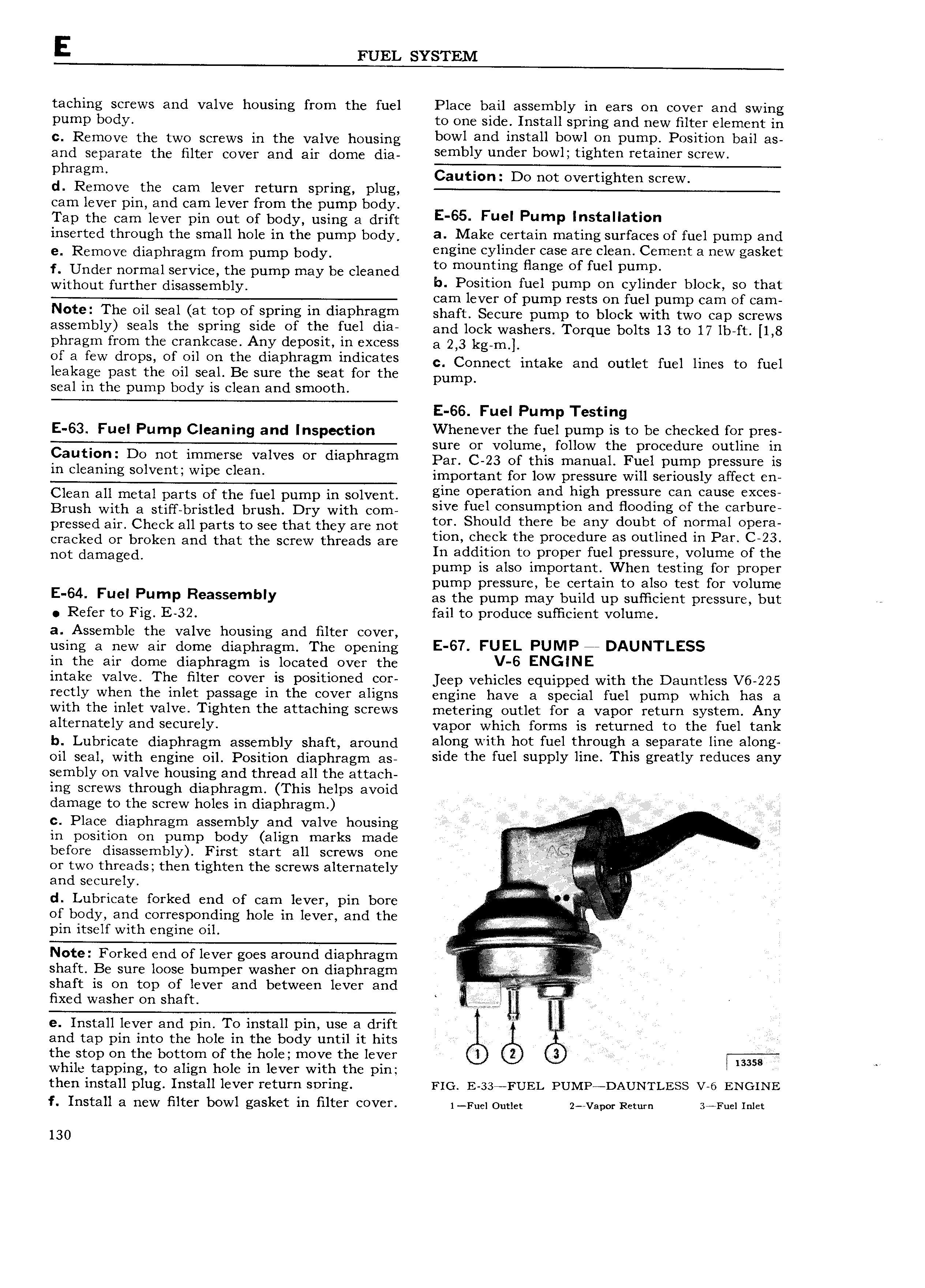

E FUEL SYSTEM taching screws and valve housing from the fuel Place bail assembly in ears on cover and swing pump body to one side Install spring and new filter element in c Remove the two screws in the valve housing bow lemd glstill liolgl all pump Ppsltlpll ball HS and separate the filter cover and air dome dia Sem Y up l OWS lg t Y U llll l l W phragm Caution Do not overti hten screw d Remove the cam lever return spring plug cam lever pin and cam lever from the pump body Tap the cam lever pin out of body using a drift E e5 Fuel PumP lnstallatmn inserted through the small hole in the pump body a Make certain mating surfaces of fuel pump and e Remeve diaphragm mm pump bOdy engine cylinder case are clean Cement a new gasket f Under normal service the pump may be cleaned to moupimg Hangc Of fuel puH p Wimeut further disassembiy lo Position fuel pump on cylinder block so that cam lever of pump rests on fuel pump cam of cam N te The Oil seal at wp Of Spflllg lll diaphragm shaft Secure pump to block with two cap screws assembly seals the spring side ef the fuel dia and loek washers Torque bolts is to 17 lb ft 1 8 phragm from the crankcase Any deposit in excess 3 2 3 kg m el 3 few deeper efell ee the dievhream mdlcaces c Connect intake and outlet fuel lines to fuel leakage past the oil seal Be sure the seat for the puma seal in the pump body is clean and smooth E 66 Fuel Pump Testing E 63 Fuel Pump Cleaning and Inspection Whenever the fuel pump is to be checked for pres Caution Do not immerse valves or diaphragm inlgie ge2 Og iisfgigiyiaieepgefgismg iilegelsiqiee IQ in cleaning Solvent Wipe elee important for low pressure will seriously affect en Clean all metal parts of the fuel pump in solvent gine Operatlen and hlgh pressure can cause eXeeS Brush with a stiiepbristlad brush Dry with eOm sive fuel consumption and fiooding of the carbure pressed air Check all pattt to tee that they att het eee Slieulel there be eey l l eei eeemel eieere cracked or broken and that the screw threads are elem elieek the procedure es Outlmed m Pee C 23 not damaged In addition to proper fuel pressure volume of the pump is also important Whenl testing ffor pqoper ump ressure be certain to a so test or vo ume E 64 Fuel Pump R 3 6mbl gs the gump may build up sufficient pressure but M Refer to Fig E 32 fail to produce sufficient volume a Assemble the valve housing and filter cover using a new air dome diaphragm The opening E 67 FUEL PUMP ee DAUNTLESS in the air dome diaphragm is located over the V 6 ENGINE intake valve The filter cover is positioned cor Jeep vehicles equipped with the Dauntless V6 225 rectly when the inlet passage in the cover aligns engine have a special fuel pump which has a with the inlet valve Tighten the attaching screws metering outlet for a vapor return system Any alternately and securely vapor which forms is returned to the fuel tank b Lubricate diaphragm assembly shaft around 8l0 g with hpt fuel thfpugh fi S p3l at li e 3l0llg oil seal with engine oil Position diaphragm as side tll fuel Supply llllp This gl 3tlY Yedllces 3llY sembly on valve housing and thread all the attach ing screws through diaphragm This helps avoid damage to the screw holes in diaphragm c Place diaphragm assembly and valve housing l in position on pump body align marks made V before disassembly First start all screws one or two threads then tighten the screws alternately i 4 i eee see rely i Y d Lubricate forked end of cam lever pin bore i li iiiii e i i of body and corresponding hole in lever and the z VVVV pin itself with engine oil i if i i r l Note Forked end of lever goes around diaphragm shaft Be sure loose bumper washer on diaphragm i I I shaft is On top of lever and between lever and iiiii fixed washer on shaft Ii Q e Install lever and pin To install pin use a drift i and tap pin into the hole in the body until it hits the stop on the bottom of the hole move the lever gf 0 mg while tapping to align hole in lever with the pin then install plug Install lever return spring rio E 33 FUEL PUMP DAUNTLESS v 6 ENGINE f Install a new filter bowl gasket in filter cover 1 pua outlet zwvhpot Rettthh sArue1 rhltt 130

Next

Next