Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

7027082

7041185

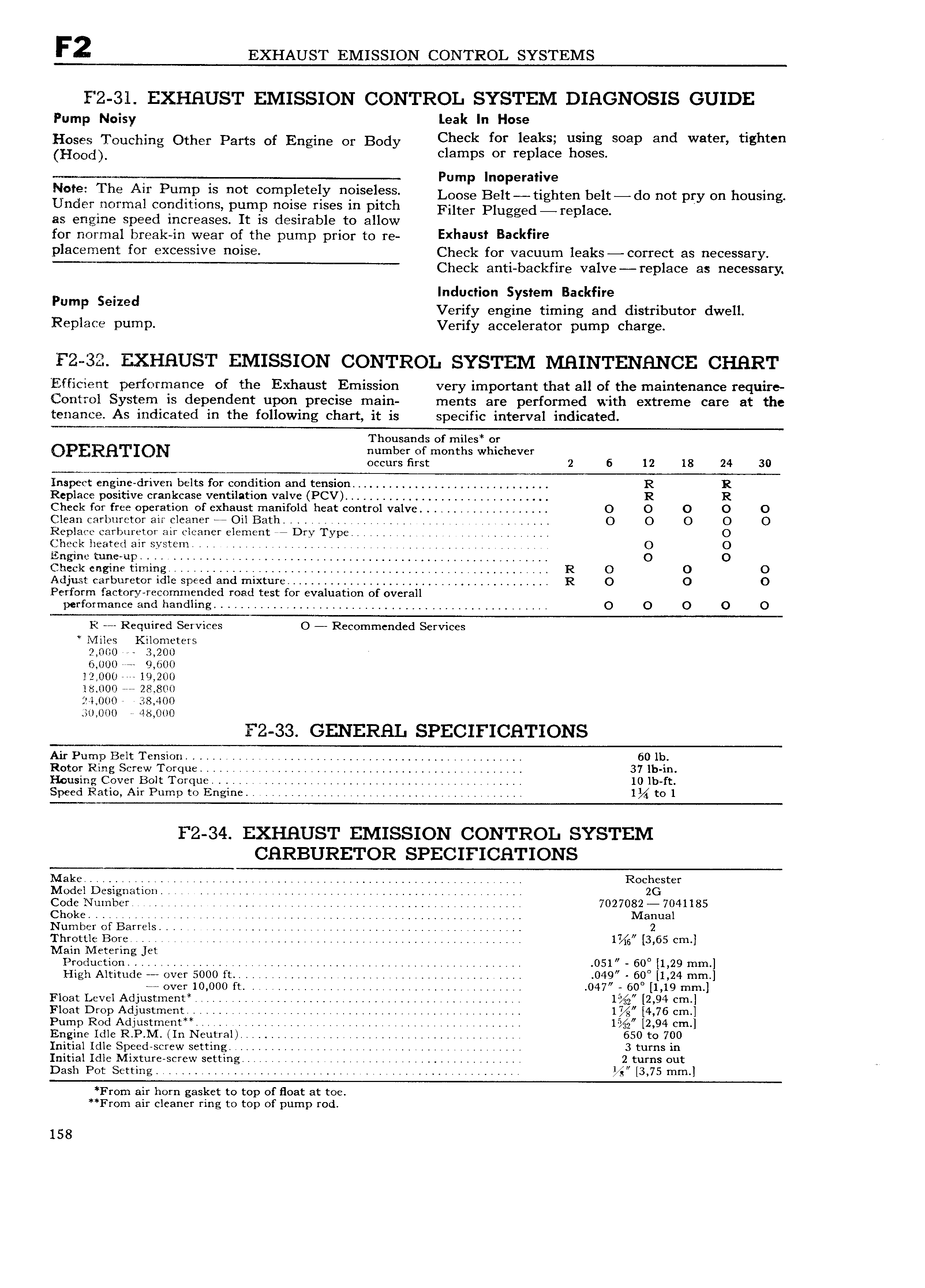

F2 EXHAUST EMISSION CONTROL SYSTEMS F2 31 EXHHUST EMISSION CONTROL SYSTEM DIHGNOSIS GUIDE Pump Noisy Leak In Hose Hoses rnncinng other Pants of Engine or Body Check f r leaks Si g S r md water sht HOOd Cl3l l 1pS Ol I pl8C hoses Pump Inoperative NME The Ar PUT is mt comllletely 1S l SS Loose Belt tighten belt do not pry on housing Un erlnormal Conditions pump IIOISB rises in pitch Filter P1ugg d plaC as engine speed increases It is desirable to allow for normal break in wear of the pump prior to re EXl UST B8 kf f Pl8 m t for excessive noise Check for vacuum 1eaks correct as necessary Check anti backfire valve replace as necessary Induction System Backfire Pump Seized Verify engine timing and distributor dwell Replace pump Verify accelerator pump charge F2 32 EXHHUST EMISSION CONTROL SYSTEM MHINTENHN CE CHHRT Efficient performance of the Exhaust Emission very important that all of the maintenance require Control System is dependent upon precise main ments are performed with extreme care at the tenance As indicated in the following chart it is specific interval indicated PE H I Thousands of miles or R number of months whichever O T occurs first 2 6 12 18 24 30 Inspect engine driven belts for condition and tension R R Replace positive crankcase ventilation valve PCV R R Check for free operation of exhaust manifold heat control valve O O O O O Clean carburetor air cleaner Oil Bath A O O O O O Replace carburetor air cleaner element Dry Type O Check heated air system A O O Engine iZune up A O O Check engine timing A A R O O O Adjust carburetor idle speed and mixture R O O O Perform factor31 rec mr11ended road test for evaluation of overall performance and handling r A O O O O O R Required Services O Recommended Services I Miles Kilometers 2 000 A 3 200 6 000 r 9 600 12 000 19 200 li 000 r 28 800 1 4 000 V 38 400 30 000 A 48 000 F2 33 GENERHL SPECIFICHTIONS Air Pump Belt Tension AA A t 60 lb Rotor Ring Screw Torque AAA A i 37 lb in Housing Cover Bolt Torque A AA AA A 10 lb ft Speed Ratio Air Pump to Engine 1 to 1 F2 34 EXHHUST EMISSION CONTROL SYSTEM CHRBURETOR SPECIFICHTIONS Make A A Rochester Model Designation A AA 2G Code Number A A 7027082 7041185 Choke A A A A A A A Manual Number of Barrels A A A 2 Throttle Bore A A A A A AA 1 3 65 cm Main Metering jet Production A A A 051 60 1 29 High Altitude over 5000 ft A 049 60 1 24 mm over 10 000 ft A 047 T 60 1 19 Float Level Adjustment A A A A A A A A AA 1 2 94 cm Float Drop Adjustment A A 1 4 76 cm Pump Rod Adjustment A 1 2 94 cm Engine Idle R P M In Neutral A 650 to 700 Initial Idle Speed screw setting A A AA A 3 turns in Initial Idle Mixture screw setting AA A A 2 turns out Dash Pot Setting A A A A 3 75 mm From air horn gasket to top of float at toe From air cleaner ring to top of pump rod 158

Next

Next