Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

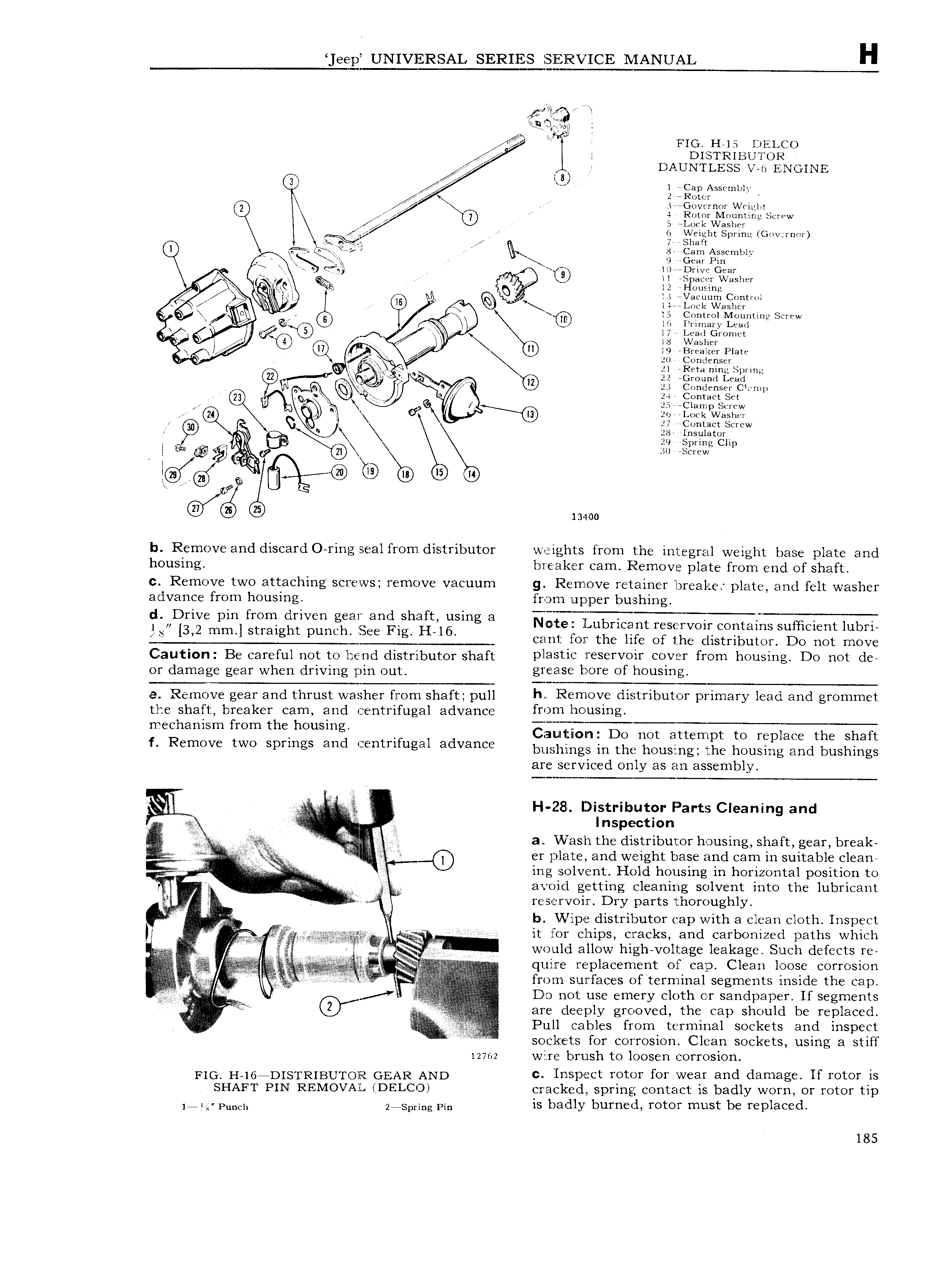

ee p UNIVERSAL SERIES SERVICE INIANUAL H K6 wig VN E V YF IG hH 15r loercci V J l DAU iiTE1 i N iNE 2 KE 1 Y Cap Asscrnllly V i riuliz 0 Q 4 Rotor Mounting Screw 7 5 Locl Washer V ii geiglit Spring Govxnor E Q af 7 ia 0 G5 XJ v V m rCan Assembly f i G f5 i P8L V I KL lg il riipacer Washer E xf 2 ii V i C A l Lock Washer 1 E rr V XUUD Q n trol Mo 1rntiiip Screw e e 2 i ra X l lo Washer 22 5rr a a r Plate 4 i 21 ondenser S Jl Reta ning Spring l 2 i r r g r pJ L M ri ES5 Z i i LEf S iQ i gimtacgSct s V 2 w am fore 4 J Rl 6 I i U Lockl asl N Fontait Screw V l V 1 Sl l H Ul I 1 E j G D R 5 cgggggs Chr lo ef i G 13400 b Remove and discard O ring seal from distributor weights from the integral weight base plate and housing b reak er cam Remove plate from end of shaft c Remove two attaching screws remove vacuum g Remove retainer breaker plate and felt washer advance from housing from upper bushing d Drive pin from driven gear and shaft using a T 1 U 3 2 mm Straight punch Sec Fig H l6 e iaubricant reservoir contains suPf1c1entlubri cant 1 r the hfc Of the clistributvr D0 not move Caution Be careful not to be nd distributor shaft D l3St1 3 1V S FV011 cover from housin D0 not de g or damage gear when driving pin out g1 iS lF 0T of h0L1S1Hg e Remove gear and thrust washer from shaft pull h R mO diSUibL1l 0Y Primary load and grommet the shaft breaker cam and centrifugal advance from l3C U 1 1g Teghamsm from th hOuSmi f I d Caultiioinz Do not attempt to replace the shaft mOV two Sprmgs an rentn uga a Vzmck bushings in the housing the housing and bushings are serviced only as an assembly ii H 28 Distributor Parts Cleaning and A V g i V Inspection Q rl an l ski the distributor housing shaft gear br 3k i i g V f G 1 er plate and weight base and cam in suitable clean ec D ing solvent Hold housing in horizontal position to l Q avoid getting cleaning solvent into the lubricant re s e r voir Dry parts thoroughly I i i i W r b VVipe distributor cap with a clean cloth Inspect 5 ligl E Af Y V 5 it for chips cracks and carbonized paths which v r 1 wgrild gllow high V0l1 3g leakage SL1Ch defects I E f ql ll Y Dl3C 1 T1 Dt of Cap Cl 3I1 loose Qorrosion ii f g V W iT i r D from surfaces of terminal segments inside the cap Yg Iavvn A U Zvi Vlvg DO nm use emu y Cloth OY Sandpapen If Segments e z V are deeply grooved the cap should be replaced Pull cables from terminal sockets and inspect sockets for corrosion Clean sockets using a stiff 12702 wire brush to loosen corrosion FIG H 16 DISTRIBUTOR GEAR AND C ilniipcct rotor for wear and damage If rotor is SHAFT PIN REMOVAL DELCO crack ed spring contact is badly worn or rotor tip Q punch Zcespmg pm is badly burned rotor must be replaced 185

Next

Next