Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

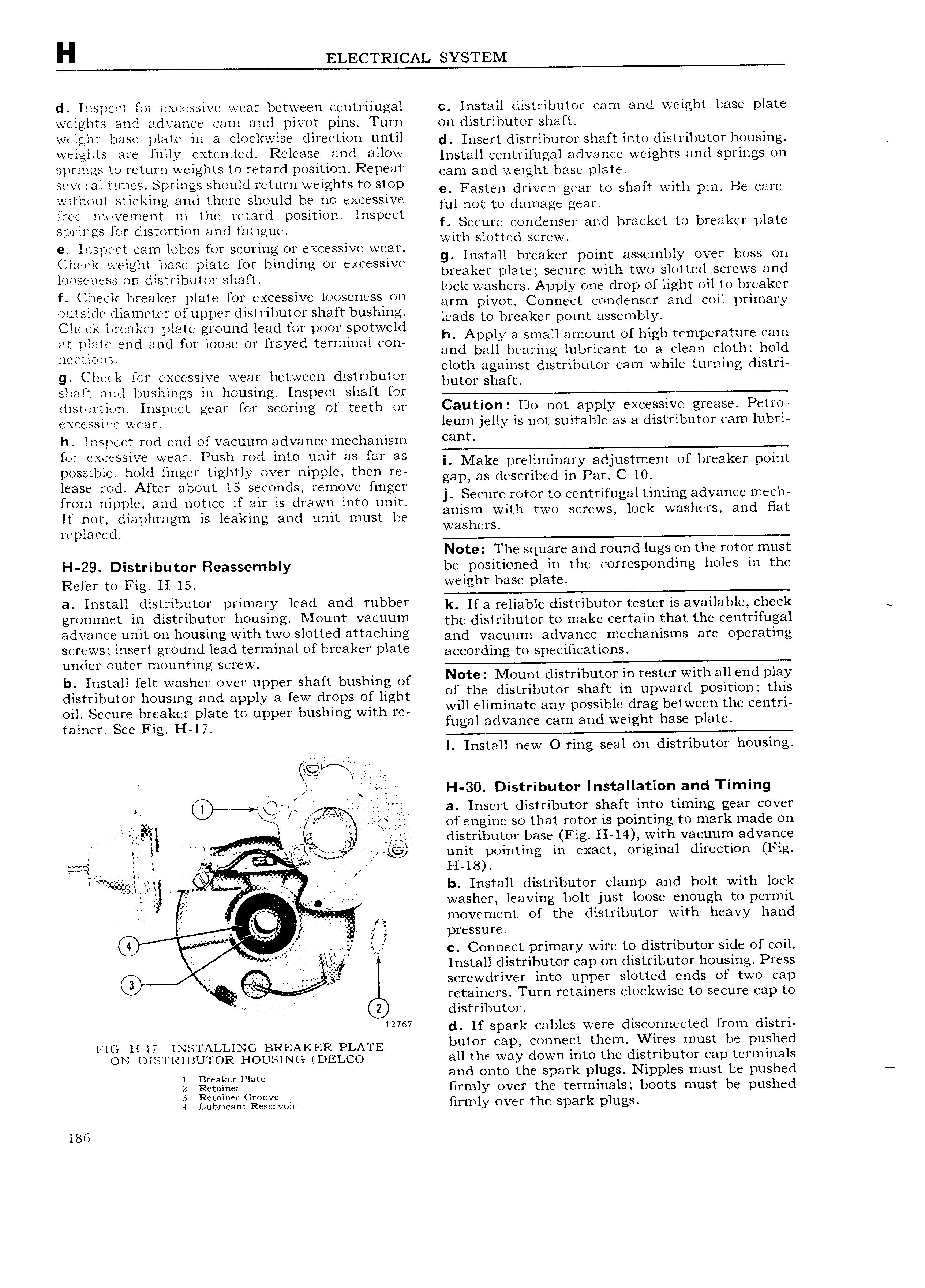

H ELECTRICAL SYSTEM cl lnsprct for excessive wear between centrifugal c Install distributor cam and weight base plate weights and advance cam and pivot pins Turn on distributor shaft W l lll llasc Plata lll a lO l WlS difectivu umil d Insert distributor shaft into distributor housing W l lilllS are lullY Xl uu l Release and allow Install centrifugal advance weights and springs on springs to return weights to retard position Repeat cam and neighi base plete several times Springs should return weights to stop e Fasmn driven ggar to shaft with pill BC Can without sticking and there should be no excessive fu nm tO damage ggas ree movement in the retard position Inspect f secu Gnd HS 3 d bm ket tO breaker late springs for distortion and fatigue X ith Sloapcd SCFCWCI n C p e lnspect cam lobes for scoring or excessive wear I tl HI b k l bl b Cheri weight base plate for binding or excessive Us i ma Bl pcmit asscm y Over OSS On iOssM l sS Cm diswibutm Shaft breaker plate secure with two slotted screws and f h k kmakp 1 A lock washers Apply one drop of light oilto breaker i l f pete fw X SSl l O SS ml arm pivot Connect condenser and coil primary outside diameter of upper distributor shaft bushing igads to breaker pmnt assembly Check breaker plate ground lead for poor spotweld h A I m H O t Of hi h tcm nature Cam at plate end and for loose or frayed terminal con a d Sglybaegrigg iglgfiignt mi C1 3 ClOth hO1d nmlilmmi cloth against distributor cam while turning distri g Cherk for excessive wear between distributor butor shaft shaft and bushings in housing Inspect shaft for distortion Inspect gear for scoring of teeth or Caution Do not apply excessive grease Petro excessive wear leum jelly is not suitable as a distributor cam lubri h Inspect rod end of vacuum advance mechanism call for excessive wear Push rod into unit as far as L Make preliminary adjustment Of breaker pOmt possible hold linger tightly over nipple then re gap as dgscribed in Par C 10 lease rod After about I5 seconds remove linger L l A I mm nipple and HOUCC if gif is drawn mm unit Securelrotor to centrifugal timing advance mech H nm diaphragm is icking and unit must be amsm with two screws lock washers and fiat replaced washers Note The square and round lugs on the rotor must H 29 Distributor Reassembly be positioned in the corresponding holes in the Refer to Fig H 15 weight base plate a Install ll tl lbut0Y Pllmaly lead and rubber k Ifa reliable distributor tester is available check glammat lll Cllstllbutal llauslllg Muuut Vacuum the distributor to make certain that the centrifugal advance unit on housing with two slotted attaching and Vacuum advance mechanisms en e Opgfating screws insert ground lead terminal of breaker plate according tc Specinceitieng under outer mounting screw b Install felt washer over upper shaft bushing of N t Moupt dlstrlbutolim tester with ailimd play distributm housing and apply 3 few drops Of iight of the distributor shaft in upward position this On Secure breaker plate tO upper bushing with r will eliminate any possible drag between the centri taineyr Sec Fig H i7 fugal advance cam and weight base plate I Install new O ring seal on distributor housing i I H 30 Distributor Installation and Timing i fs a Insert distributor shaft into timing gear cover i AQ of engine so that rotor is pointing to mark made on l V i lifes distributor base Fig H 14 with vacuum advance i j i unit pointing in exact original direction Fig 5 i L b H 18 li lli b Install distributor clamp and bolt with lock l r I F Ls washer leaving bolt just loose enough to permit M movement of the distributor with heavy hand l V fl pressure I A l ix c Connect primary wire to distributor side of coil n Install distributor cap on distributor housing Press 8 A V screwdriver into upper slotted ends of two cap Wi retainers Turn retainers clockwise to secure cap to it distributor l2767 d If spark cables were disconnected from distri NGA HU INSTALLING BREAKER PLATE butor cap connect them Wires must be pushed QN DISTRIBUTQR HgU5lNG DEl i all the way down into the distributor cap terminals I W Breaker Plate and onto the spark plugs Nipples must be pushed i 1 i GrOOv firmly over the terminals boots must be pushed 5 LQi nCam Remveir firmly over the spark plugs 18ti

Next

Next