Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

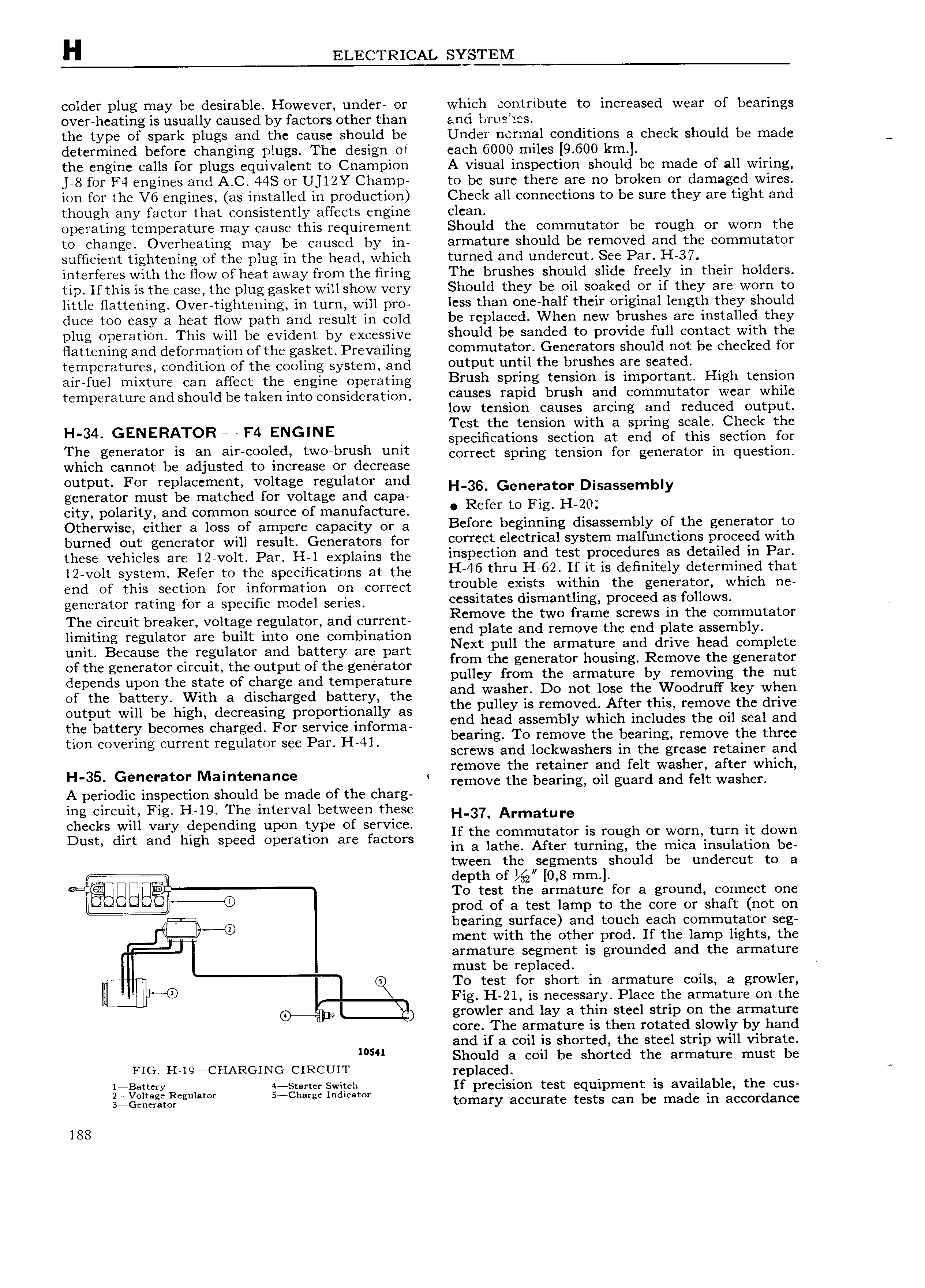

H ELECTRICAL SYSTEM colder plug may be desirable However under or which contribute to increased wear of bearings over heating is usually caused by factors other than and brus 1es the type of spark plugs and the cause should be Under normal conditions a check should be made V determined before changing plugs The design of each 6000 miles 9 600 km the engine calls for plugs equivalent to Champion A visual inspection should be made of all wiring J 8 for F4 engines and A C 44S or U Il2Y Champ to be sure there are no broken or damaged wires ion for the V6 engines as installed in production Check all connections to be sure they are tight and though any factor that consistently affects engine clean operating temperature may cause this requirement Should the commutator be rough or worn the to change Overheating may be caused by in armature should be removed and the commutator sufficient tightening of the plug in the head which turned and undercut See Par H 37 interferes with the flow of heat away from the firing The brushes should slide freely in their holders tip If this is the case the plug gasket will show very Should they be oil soaked or if they are worn to little ilattening Over tightening in turn will pro less than one half their original length they should dugg tug easy d heat flew path and result in cpld be replaced When new brushes are installed they plug Operdtidd This will be evident by gxcggsivg should be sanded to provide full contact with the Hgttgning and dgfgymatign Of the gasket Pygvailing COH lI IlL1lZ2 lZOI Generators ShOL1ld 1 lOlZ be checked OT temperatures condition of the cooling system and Output until tho brushes No S at d air fuel mixture can affect the engine operating Brush spring tensien is important High tonsron temperature and should be taken into consideration fausecs rapid brush and commiutatgr vn Ear while ow ension causes arcmg an re uce ou pu M4 T EF4 QE d 2 d ii S1 t Y i E2 fiZl l E2 The genetatet is an arr oOO1od twe brush unit correct spring tension for generator in question which cannot be adjusted to increase or decrease output For replacement voltage regulator and H 36 Generator Disassembly generator must be matched for voltage and capa city polarity and common source of manufacture Refer te Flg Otherwise either a loss of ampere capacity or a Bororo beginning disassembly ortho ge er t r t burned out generator will result Generators for c rre t e1eetr ea1system malfunctions Pfooood with these vehicles are 12 volt Par H 1 explains the lnsoootlon and tost preeedures as dotonoo in Por 12 volt system Refer to the specincations at the H 46 thru H 62 lf it is definitely determined that end of this section for information on correct trenble oXr t within tho generator Which n generator rating for a specific model series oossrtatos dismantling Prooood os fellows i The circuit breaker voltage regulator and current Remeve tne twe name eerewe In tne cemmuteter limiting regulator are built into one combination gd plete enhd remove the enddplnte Seeeglmbly 1 unit Because the regulator and battery are part ext Pnl t e nrmnture end me ce eemp etc of the generator circuit the output of the generator from the generator nenelng Remevc tne genereter depends dpdd the state of charge ddd empddddd Pulley fiom the efmetufehbyvgcmevgekthe gut of the battery With a discharged battery the and Wee en De net lege t e eedm ey W en ddrpdt will be high decreasing prdpdrdddddy dd the Pulley rs removed ge the femevelthc img the battery becomes charged For service informa end heed assembly Wnle lneludee the el see en tion covering current regulator see Par H 41 been Ing Te remove tne neenng femeve tne tnree screws and lockwashers in the grease retainer and H 35 Generator Maintenance remove the retainer and felt washer after which remove the bearing oil guard and felt washer A periodic inspection should be made of the charg ing circuit Fig H 19 The interval between these H 37 Armature Checks will my eeeeedieg me type Of S Wi rr dd CO1 IllT1 1t3tOI is rough dr Wdm turn it ddwd Dusn dirt and high Speed Operation are factors in a lathe After turning the mica insulation be tween th s fgments lshould be undercut to a c depth of 32 0 8 mm To test the armature for a ground connect one Q prod of a test lamp to the core or shaft not on bearing surface and touch each commutator seg ment with the other prod If the lamp lights the armature segment is grounded and the armature must be replaced To test for short in armature coils a growler Fig H 21 is necessary Place the armature on the growler and lay a thin steel strip on the armature core The armature is then rotated slowly by hand and if a coil is shorted the steel strip will vibrate 1 5 Should a coil be shorted the armature must be FIG H l9 CHARGING CIRCUIT I cp ac d 1 B nery 4 S rt r Switch If precision test equipment is available the cus 2vVoltage Regulator 5 Ch rge Indicator 3 GC m tomary accurate tests can be made in accordance 188

Next

Next