Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

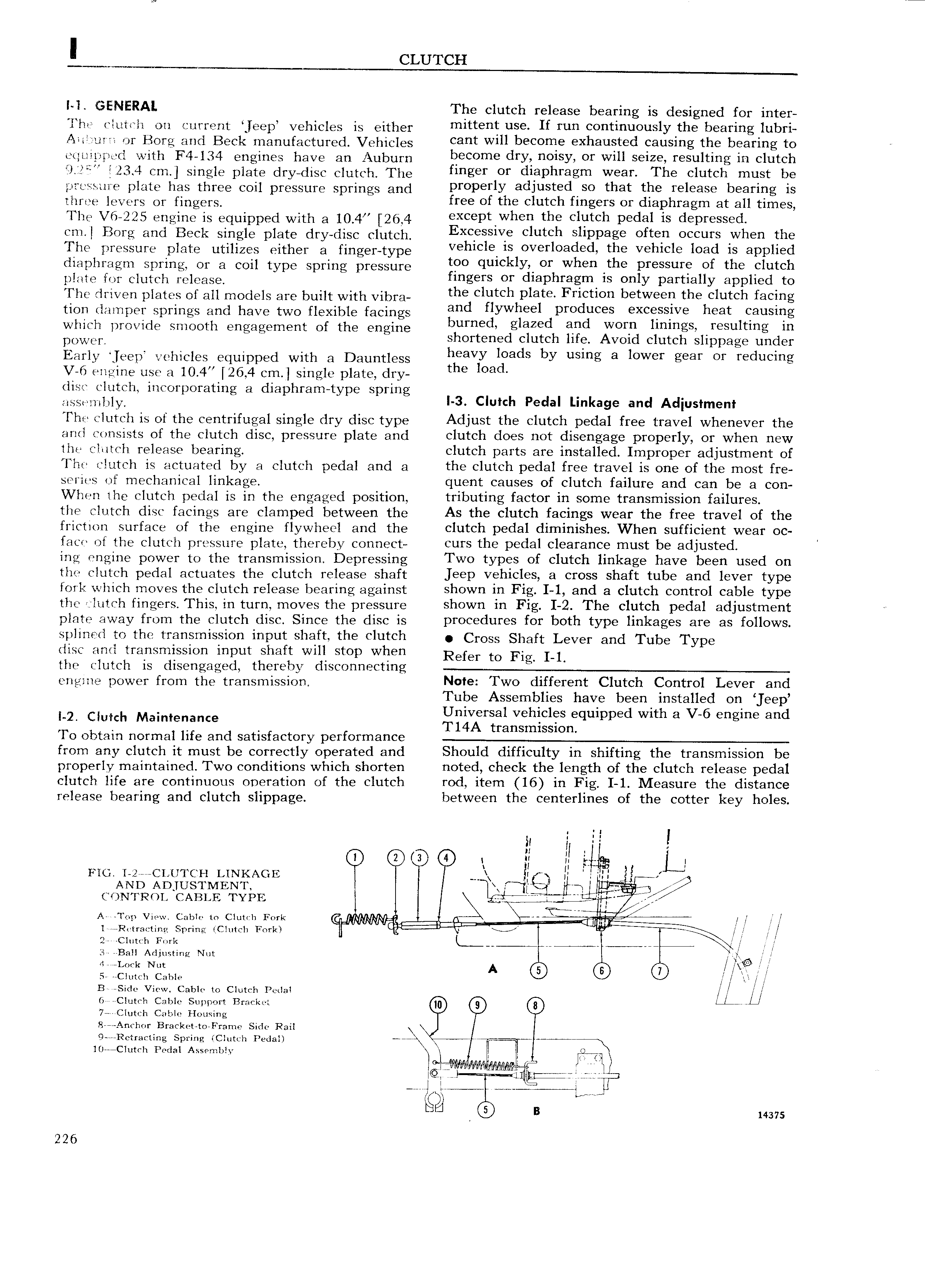

l CLUTCH I l GENERAL The clutch release bearing is designed for inter Thw clutch on current leep vehicles is either mitteet use Ir rua cOrrrrnueusrY the bearing rubrr Aiwuire or Borg and Beck manufactured Vehicles eam will beeerrre exhausted eausrng the bearing to a p pp ti withiF4 134 engines have an Auburn beeeme dry isy er will seize resultiris in clutch 9 2 a 23 4 cm single plate dry disc clutch The firmer er draprrragrrr wear The eluteh must be i t sszir e plate has three coil pressure springs and properly adjusted se that rue release bearrrlg is hwg IQVHS Or mg rS free of the clutch fingers or diaphragm at all times The v6 22s ppgmp is equipped with 3 10 4 26 4 eXeePt Whe the Clutch Pedel is depressed cm l Borg and Beck single plate dry disc clutch Exccssure crutch shepese eftee Occurs Wherr the The pressure plate utilizes Either 3 fmgeptype vehicle is overloaded the vehicle load 1S applied diaphragm spring or a coil type spring pressure pe q 1ek1 g erhWhe the Fressuie Er thelcrgrcfh plate for clutch release mg 1 S OY 1313 f3g1 H 1S On y par 13 y app 16 o The driven plates of all models are built with vibra the crutch plete Frrctraa betweee the crutch racrag tion damper springs and have two flexible facings ind gywaaardpradgcas cxcissrve hear Isausrag lah r d g U t f th urne gaze an worn 1n1ngs resu ing in i rIDrm1 9 smOO 1 Qngdgamen O 8 enema shortened clutch life Avoid clutch slippage under Early leep vehicles equipped with a Dauntless gjevly gaads by usmg a lewef gear Or raaucrag V 6 engine use a lO 4 26 4 cm single plate dry 8 ee disc clutch incorporating a diaphram type spring 3 CI t h P d I L k d Ad SS j y u c e a in age an Iustment The clutch is of the centrifugal single dry disc type Adjust the clutch pedal free travel whenever the and consists of the clutch disc pressure plate and clutch does not disengage properly or when new the clutch release bearing clutch parts are installed Improper adjustment of The clutch is actuated by a clutch pedal and a the clutch pedal free travel is one of the most fre serics of mechanical linkage quent causes of clutch failure and can be a con When the clutch pedal is in the engaged position tributing factor in some transmission failures the clutch disc facings are clamped between the As the clutch facings wear the free travel of the friction surface of the engine flywheel and the clutch pedal diminishes When sufficient wear oc A face of the clutch pressure plate thereby connect curs the pedal clearance must be adjusted ing engine power to the transmission Depressing Two types of clutch linkage have been used on the clutch pedal actuates the clutch release shaft Jeep vehicles a cross shaft tube and lever type fork which moves the clutch release bearing against shown in Fig I 1 and a clutch control cable type the lutch fingers This in turn moves the pressure shown in Fig I 2 The clutch pedal adjustment plate away from the clutch disc Since the disc is procedures for both type linkages are as follows splined to the transmission input shaft the clutch Cross Shaft Lever and Tube Typg disc and transmission input shaft will stop when Refer to Fig I 1 thc clutch is disengaged thereby disconnecting engine power from the transmission Note Two different Clutch Control ever an Tube Assemblies have been installed on eep Universal vehicles equipped with a V 6 engine and liz mulch Mamreaanre T14A transmission To obtain normal life and satisfactory performance from any clutch it must be correctly operated and Shou d d1ff1cu ty in shi ting t e transmission e properly maintained Two conditions which shorten noted check the length of the clutch release pedal clutch life are continuous operation of the clutch rod item 16 in Fig I 1 Measure the distance release bearing and clutch slippage between the centerlines of the cotter key holes ly ll r 3 Maris lu FTC 3 CLUTCH LINKAGE l I J AND ADJUSTMENT sj as f NTRUI CABLE TYPE ir T riri i J e Q A Top View Cable to Clutch Fork IJ L i A q jpi r r If I i l R Yra 2tina S rine Gimp Fork V Ze Clnrrvh Fiwkp rr L r i t 1 Ball Adjusting Nut if 4 Lock Nu A i jr S Clut h Ciable 6 0 i ri Jl fl B Sido View C ble t Clutch Pedal 6 Clutch Cabl0aSupp rt Bracket Q 0 7 Clutch Cable Housing 8 Anchor Brackc t to Franie Side Rail e Rctracling Spring Clutch Pedal were Y so me rr r lU Clutcl1 Pedal Assembly U C W f lip e T l Eel B 14375 226

Next

Next