Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

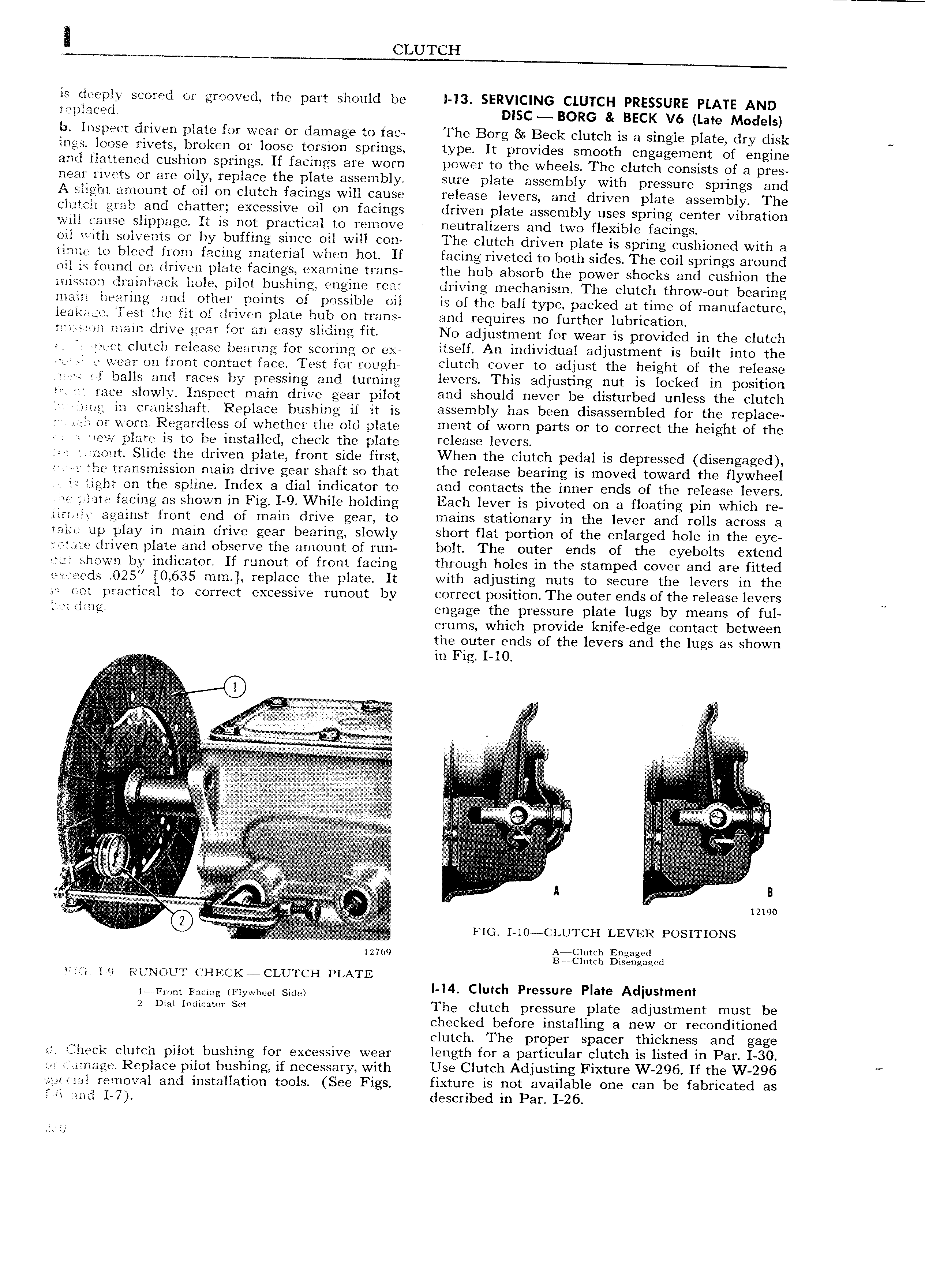

H CLUTCH is deeply scored or grooved the part should be I T3 SERVICING CLUTCH PRESSURE PLATE AND rr pla erl DlSC BORG BECK V6 Late Models b Inspect driven plate for wear or damage to fac The Borg Beck clutch is a single plate dry disk ings loose rivets broken or loose torsion springs type It provides smooth engagement of engine and flattened cushion springs If facings are worn power to the wheels The clutch consists of a pres near rivets or are oily replace the plate assembly sure plate assembly with pressure springs and A slight amount of oil on clutch facings will cause release levers and driven plate assembly The clutch grab and chatter excessive oil on facings driven plate assembly uses spring center vibration will cause slippage It is not practical to remove neutralizers and two flexible facings oil with solvents or by buffing since oil will con The clutch driven plate is spring cushioned with a tinue to bleed from facing material when hot If facing riveted to both sides The coil springs around oil is found on driven plate facings examine trans the hub absorb the power shocks and cushion the mission drainbacl hole pilot bushing engine rea driving mechanism The clutch throw out bearing main bearing and other points of possible oil is of the ball type packed at time of manufacture ieakagge Test the fit of driven plate hub on trans and requires no further lubrication ini i ni main drive gear for an easy sliding fit No adjustment for wear is provided in the clutch t V ri igtjt Clutch rgylgggg bgglring fOr gcgyjng gr gy itself AH individual 3djLlSU 1 l Ht is built into l 1 wear on front contact face Test for rough clutch 0V F tn adjust tht height of the f lcase pf balls and races by pressing and turning levers Tl1lS 8 ljL1Sti1 1g nut is locked ill position xi race slowly Inspect main drive gear pilot and should never be disturbed unless the clutch r twig in crankshaft Replace bushing if it is asscmbly has been disassembled for the replace or wom Regardless of whetlier the old plate mcnt of worn parts Or to correct the height of thc new plate is to be installed check the plate release l V rS slmit Slide the driven plate front side first When thc clutch pedal is dcprssscd disengaged a he transmission main drive gear shaft so that the release bearing is moved toward the flywheel i gigm On the splint Index 3 dial indicator to and contacts the inner ends of the release levers rw plate facing as shown in Fig L9 While holding Each lever is pivoted on a floating pin which re iirin v against front end of main drive gear to mains stationary in the lever and rolls across a mite up play in main drive gear bearing slowly short flat portion of the enlarged hole in the eye r i i driven plate and observe the amount of run bolt The outer ends of the eyebolts extend shown by indicator If runout of front facing through holes in the stamped cover and are fitted exceeds O25 0 635 mm replace the plate It with adjusting nuts to secure the levers in the not practical to correct excessive runout by correct position The outer ends of the release levers M sling engage the pressure plate lugs by means of ful crums which provide knife edge contact between the outer ends of the levers and the lugs as shown VA V V in Fig I 10 v i V I s X E2 li ili l l i i i rl 2 6 i l i i i S S f l I f f i i i lli ll i liil i l lli lli ii I ili it tf fr t l l i lli r l lr l i i o f i l r i r r i f e i l i i i at l i Q tl i I i i l tir iis lttiii i l t i V I l il f i i A i 4 i I i l l l li QZQ imo i in Q l Z I i l EY i li I i l il t L FIO I IOr OI UTOII LEVER POSITION S si latzlx i i s t lie VRUNOUT CHECK CLUTCH PLATE FX m Facing Fxywhecl Side I I4 Clutch Pressure Plate Adjustment 2 Dial I li at Sei The clutch pressure plate adjustment must be checked before installing a new or reconditioned clutch The proper spacer thickness and gage ti Check clutch pilot bushing for excessive wear length for a particular clutch is listed in Par I 30 il iTl l ig Replace pilot bustling if necessary with Use Clutch Adjusting Fixture W 296 If the W 296 tial removal and installation tools See Figs fixture is not available one can be fabricated as nid I 7 described in Par I 26

Next

Next