Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

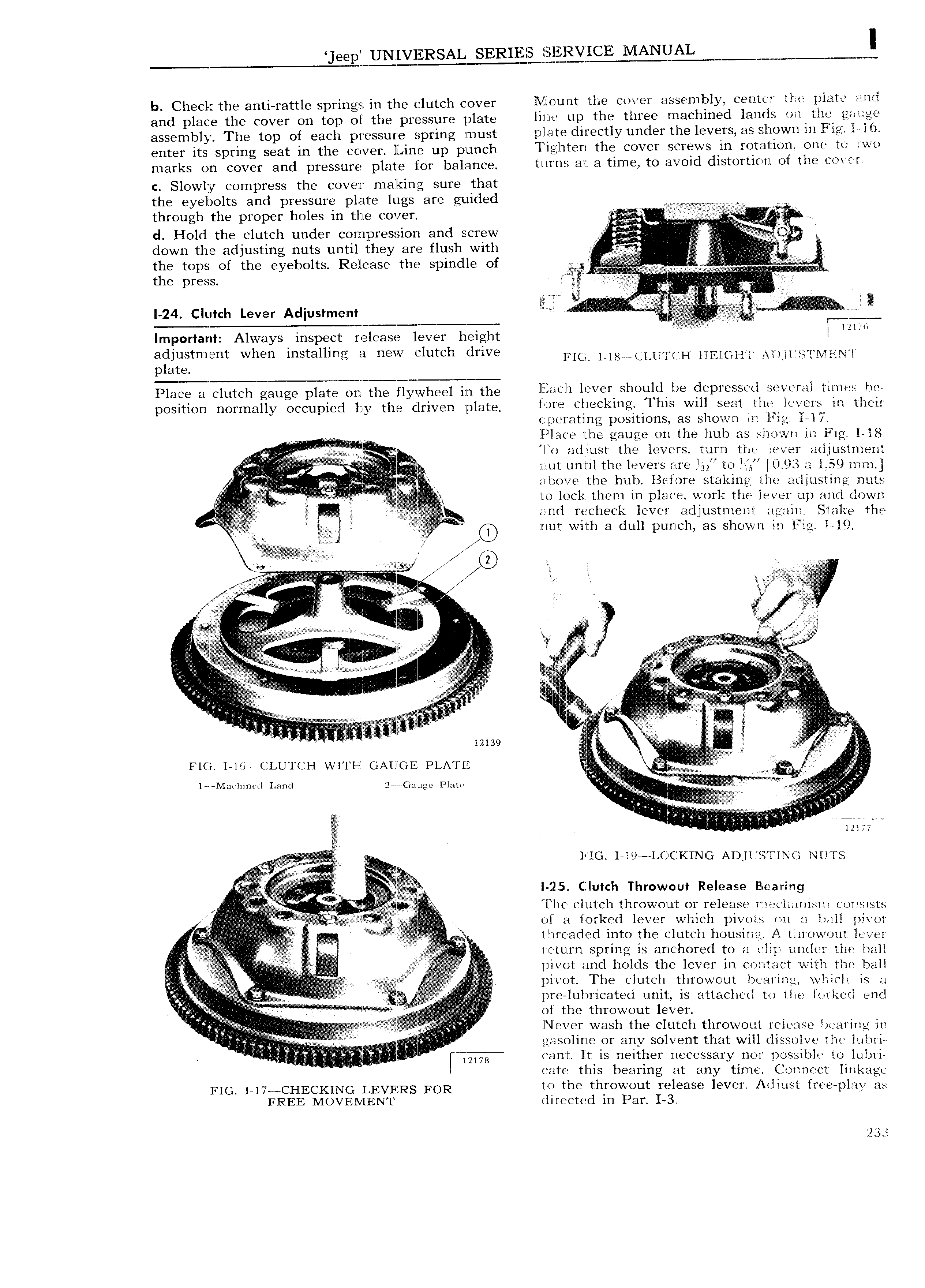

eep UNIVERSAL IVIANQAL H w b Check the anti rattle springs in the clutch cover l Yloun t the CUA i I assemhly centrr the plate and and place the cover On mp Ol the pressure plate lim up the three machined lands r ri tli e4 gaaaqge assembly The top of each pressure spring imust plate directly under the levers as shown in l ig l l ti enter its spring seat in the cover Line up punch rl l hl 1 lhs V Y S Y W in Y ml lOl Om YU l marks Og Cover and pressure plate for balance l lll I1S ali 3 HUG to Z3VOld d1StOI IlOlll of the CCBVQF c Slowly compress the cover making sure that the eyebolts and pressure plate lugs are guided aal aNWalT l w y through the proper holes in the cover V I Q A rt cl Hold the clutch under cornprezssion and screw 1 l clown the adjusting nuts until they are flush with the wps f the eyebolts F i S l the Svindl of T 5 j o o v l the press F Y r e LH I 24 Clutch Lever Adlustmeinlr i Important Always inspect release lever height I adjustment when installing 1 new clutch drive FIG me grr g cclylecll HEIGH l I ll 1 Nlll N l plate lplace a clutch gauge plate all the flywheel lll the ll Za l i lever should he depressed several times he pesltlca normally Occupied lily tlh 9 clrlvea plate lore checking This will seat lhe levers in their lperati ng positions as shown in Fig l l7 e Ae lr V l lac e the gauge on the hub as shown in Fig I l8 z l Vr Z V l ia r adjust the levers turn thx lever adjustment I riut until the levers a re l to llf 0 93 zz 1 59 mm 2 1 i i 3 e l j I r r hove 1 he huh Betore staking rho adjusting nuts F I V lo lock them in place work the lever up and down r g ri nd recheck lever adjustmem agjaui Stake the l nut with a dull punch as shown in Fig l l9 ifi 5 V Yil y Z J r i El l A r lr 4 s f F Q owl F 7 ei I Y I 3 7 4 i fh V Y V7 ii ii4 i VM will r lr 5 il it D l 3c W i il l ily is ew X fijf r r Eva Lian cl MMS el MMV 4 4 V a R i il l i l T t We l l i r r E r ill lr l 2 i y r l r r i2139 r v l i V Frou 1 16 e jLU l CI I Wl l l l GAUGE PLATJZE i li M l Ma l1ii1 rl Land 2 r G Jg0 Plain w i i i f i i CY l i 1 r iii F c zi l T gizi 7 E PIG I l 1 LC CTKING AD lU l ll 1iQ Ntirs 4 s r r r I i I A M Clutch Throwcut Release Biear ing rf ly in l l ll l Cl 1 tl l OWOlL1 lf Ol l HS l l fC lirlillSll i Cl lll lSl S V ol a forked lever which pivots on a l ll pivot r l u eaded into the clutch housinlg A tlirowout ltver r r i F j l ieturn spring is anchored to a clip under the hall pivot and holds the lever in co ua ct with the ball 1 V E lirvot Phe clutch throwout heariiirg which is a I V A e V liz pre uljiricatedl unit is attached to The iiurlicil end V ii G l r i lii l i i i V Z il J i the throwout lever i L t V V Never wash the clutch throwout release hearing in if l V V lzasoline or any solvent that will dissolve the luhri E l jT7 a want It is neither necessary nor possible to lubri Z T ilj f this bearing at any time Connect linkagc FlG l ly CHECKlNG LIEVEZRS FC R to the throwout release lever Adiust free play as FREE Mov12cMEN r 1iret i ed in Par I 3 2 3

Next

Next