Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

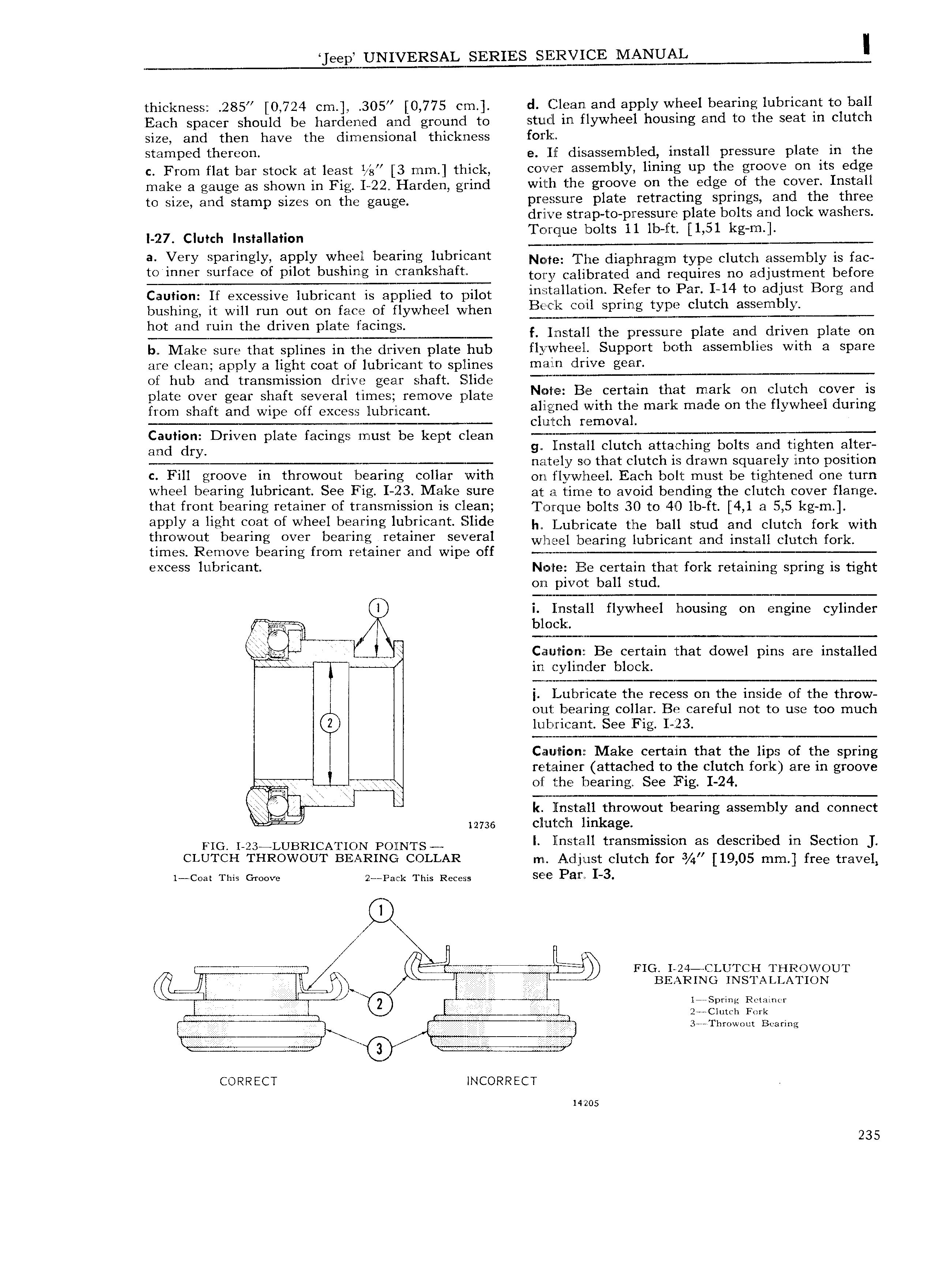

jeep UNIVERSAL SERIES ICE lVlANU L I thickness 285 0 724 cm 305 0 77 5 cm d Clean and apply wheel bearing lubricant to ball Each spacer should be hardened and ground to stucll in flywheel housing and to the seat in clutch size and then have the dimensional thickness forlsx stamped 1 hereon e If disassembled install pressure plate in the c From flat bar stock at least 3 mm thick cover assembly lining up the groove on its edge make a gauge as shown in Fig I 22 Harden grind with 1 he groove on the edge of the cover Install to Silo and Stamp Sizog on tho ggugg pI 4E3SSUlT plate I tI 3 CiClI lg SpI 1I1gS and tl 1 tl lI drive stra to ressure late bolts and lock washers p 111 lbf p 1 1 k r 27 a E 1 fiEli Yi fL L E Z L a Very PaYi 1Y QPPIY Wh l bearing lllbmiam Note The diaphragm type clutch assembly is fac E Inner Surface Of pllot bushffg m fE lihaft tory calibrated and requires no adjustment before Caution If excessive lubricant is applied to pilot 1 ii ll iitl 0 R i i to P8 L 4 to Hdilliiit Borg and bushing it will run out on face of flywheel when Sprmg ty C utc assgrjn Y TL and mm th d f l V p1at i iiH c i i f jlnstiall the pressure plate and driven plate on bn l aka Sum that splines in tht diyiveti plate hub flj5wwheel Support both assemblies with a spare are clean apply a light coat of lubricant to splines miliifl df lV6 g6 i1 of hub and transmission drive gear shaft Slide 1 h plate over gear shaft several times remove plate N E l E Cermm tlf t mark OI hutch C O l er ls from shaft and wipe off excess lubricant a i n j Wlth ml mark made On t G YW eel urmg L c utc 1 remova C t D I l t f 5 i b k t l j 8 Iggy Ul en p 3 G acmg mus Q Gp C ean g Install clutch attaching bolts and tighten alter L t t 1 nately st that clutch is drawn gquayoly into position c Fill groove in throwout hearing collar with on flywheel Each bolt must be tightened one turn Wh66l b63Yi g lL1b1 iC8Ht 66 Fig I 23 M lke SU1 6 at a time to avoid bending the clutch cover flange that front bearing retainer of transmission tis clean Ti rqu e bolts 30 to 4 l lb ft 4 1 a 5 5 kg m apply a light coat of wheel bearing lubricant Slide hw Lu b r Cat the ball Stud and Clutch fork with tllmwout bearing QVEY beam g Hamer al wheel bearing lubricant and install clutch fork times Remove bearing from retainer and wipe off excess lubricant Nnlle Be certain that fork retaining sprin is ti ht g E on pivot ball stud l i ljrnstall flywheel housing on engine cylinder t I b l ocl Q r Y A C El 1lii lI 22 Be ce rtain that dowel pins are installed 7 in cylintler block i Luhricate the recess on the inside of the throw out bearing collar Be careful not to use too much 2 lul i ricar1t See Fig I 123 C z u1ti r1 Make certain that the lips of the spring retainer attached to the clutch fork are in groove i of the bearing See Fig I 24 Iii mm i k llnstall throwout bearin assembl and connect wd 1 in 1 k g Y rugs c utc in age FIG I 23 LUBRICATION POHNTS I llnstall transmission as described in Section J crurcn Tnaowour B12 lR1Nc coLL AR mi A dji ist clutch for 3 ii 19 05 mm free travel l Coat This Groove 2 Pack This Recess s 7 PHY I 3 2 6 g tf Eii FIG I 24 CLU I CH Tl II l WOUT BEARING INSTALLATION 4 lf Spring Retainer t 2 Clutch Fork M lJ 3 Throwout Bearing Q i D Gy 1r w CORRECT INCORRECT 14 2 05 235

Next

Next