Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

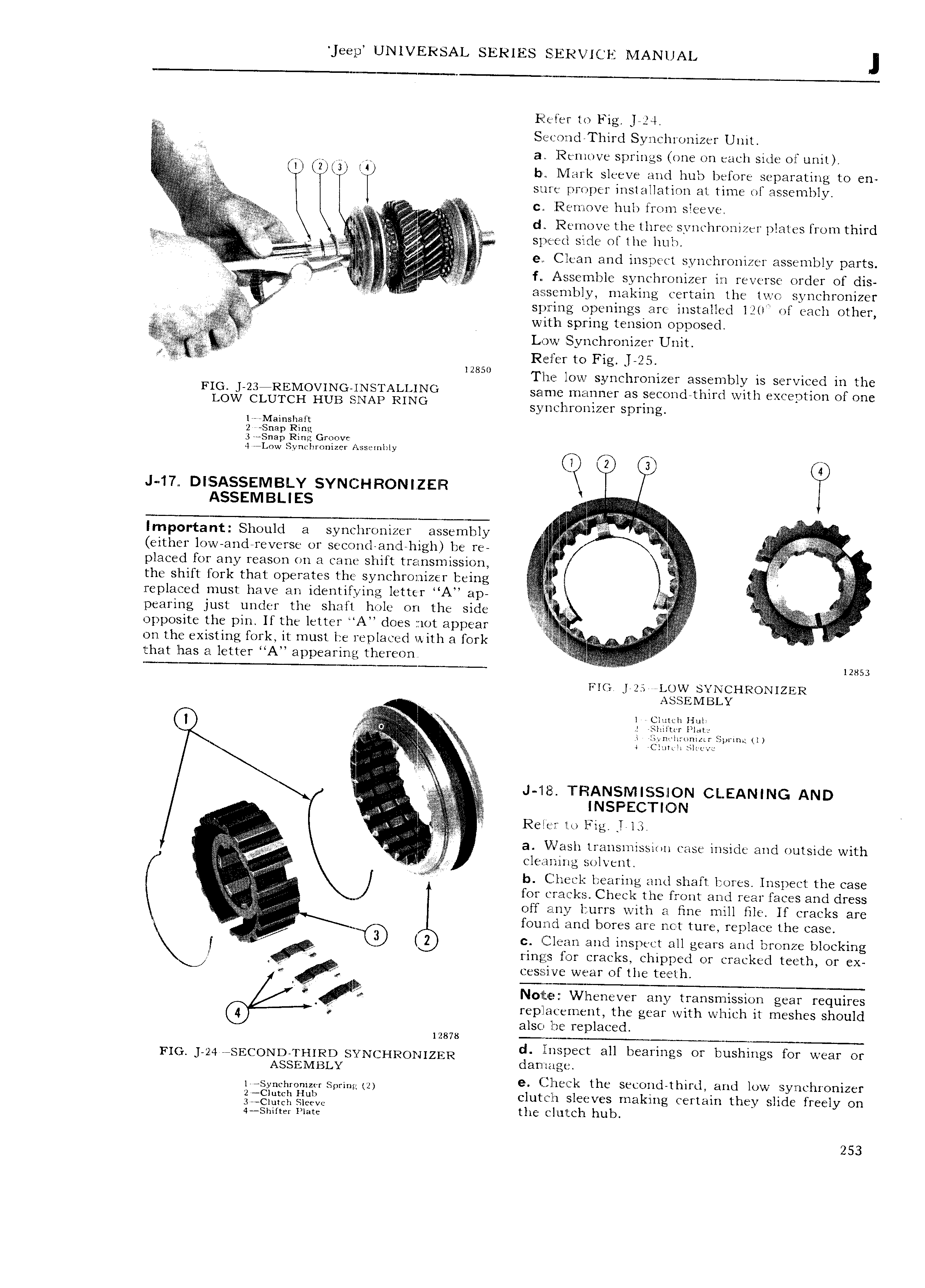

Iee 1 UNIVERSAL SERIES SlE R I l IANUAL J I EZT t et to Fig I 24 Second Third Syn hronizer Unit a Remove springs one on each side of unit I I U U U bi Mark sleeve and hub before separating to en i sure rc Jer installation at time of assembl 2 V I y i i W A c Reniiove hub from sleeve i i 2 Y 13r i Fit 2 d R erno ve the three synchronizer plates from third is V S 4 S Q 4i Z l side of the limb ii if l i e Clean and inspect synchronizer assembly parts A l i i f Assemble synchronizer in reverse order of dis f S assembly making certain the two synchronizer spring openings are installed l2 of each other with spring tension opposed iiii Ss Low Svnchronizer Unit 5 o r Reiler to Fig I 2E 12850 I ii e low synchronizer assembly is serviced in the FIG J 23 REMOVINGQINSTALLING same manner as secondthird with exception of one LOW CLUTCH HUB NAP RING Sym hI miZ Y Spring I Mainshaft 2 Snap Ring 3 Snap Ring Groove 4 Low Synchronizcr Assembly M i 2 1 4 J 1 DITSASSEIVIBLY SYNCZHRONIZEIR ASSEIVIBLIES g Y Important Should a synchronizer assembly iiiii either low and reverse or second an l high be re placed for any reason on a cane shift transmission K i i the shift fork that operates the synchronizer being replaced must have an identifying letter A ap pearing just under the shaft hole on the side ti g opposite the pin If the letter A does not appear se A izy g on the existing fork it must be replaced w ith a fork i that has a letter A appearing thereon I e FIG Ir2i LOW SYINICHRONIZELR ASSEMBLY t g l Clutch Hul I 1 siiirt r mate K iiylnelironiztr Sprint I 4 rCIt1Itlii l1 t v i J IE TFIANSIVIIESSIION CLEANING AND y Ei i NSPECTWN I I Rem l rig J ia a j A a Vl ash transmission case inside and outside with cle 1n ing solvent i b Check hearing and shaft bores Inspect the case V for cracks Check the front and rear faces and dress off ariy burrs with a fine mill tile lf cracks are 1 I found and bores are not ture replace the case 2 c Clean and inspect all gears and bronze blocking yi rings for cracks chipped or cracked teeth or ex 1 cessi ve wear of the teeth r V E2 t Tf wa N01 Eie i Wlnenever any transmission gear requires j replacement the gear with which it meshes should also be replaced 1 287u FIG J 24i SECOND4THIRD SYNCHRONIZER d fnspect all bearings or bushings for wear or ASSEMBLY d ifllelgti lrgsymhmnmr Sprmmh e Zlhecl the second third and low sytnchronizer 2 C1urch Hub clutcl 1 sleeves making certain they slide freely on 3e Clutch Sleeve 4 4 ssarm mate the clutch hub 253

Next

Next