Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

998386

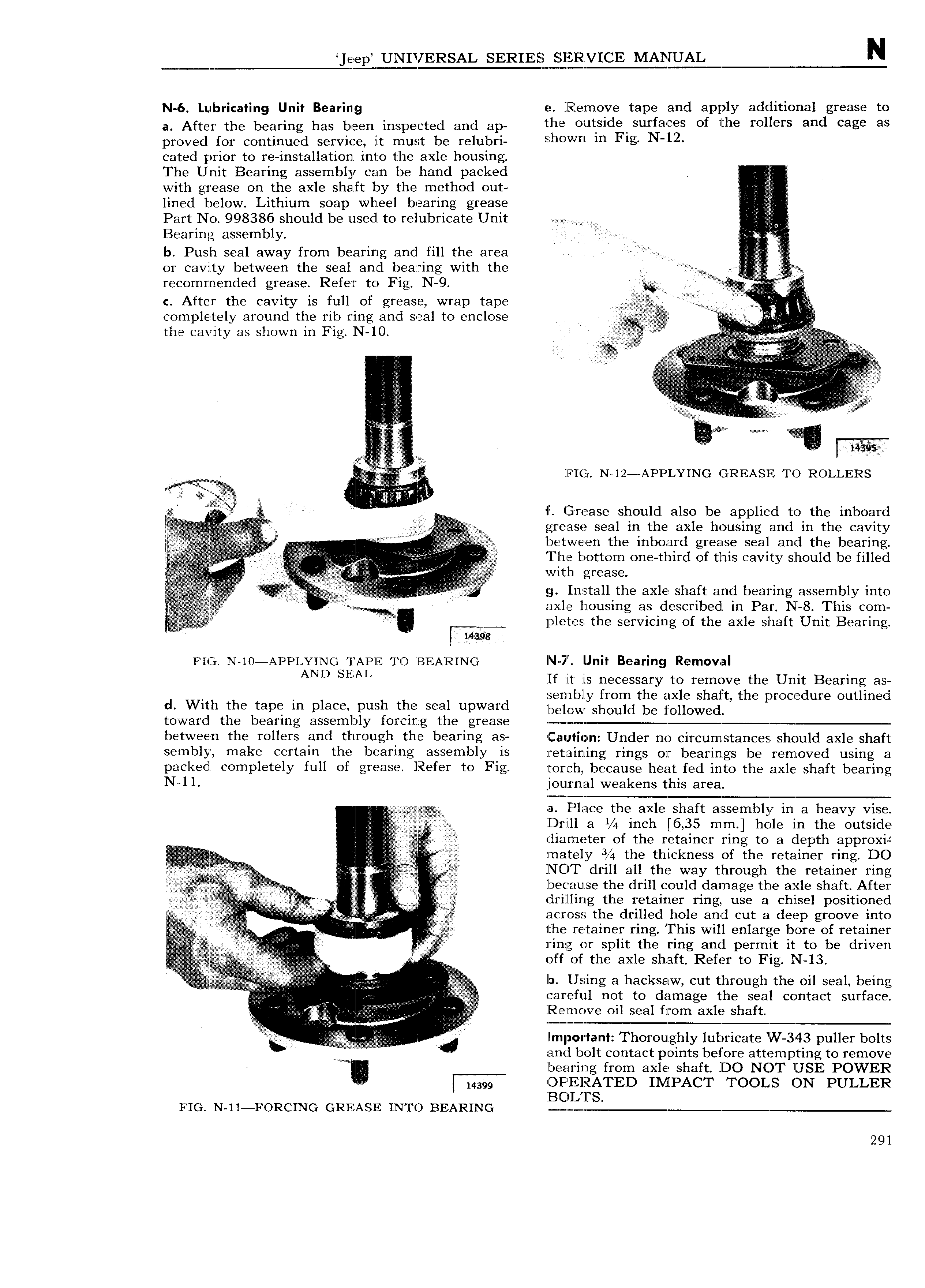

eep UNIVERSAL SERIES SERBVICE MANUAL N N 6 Lubricating Unit Bearing e Remove tape and apply additional grease to at After the bearing has bfitan imspeeted and ep the outsidelsurfaces of the rollers and cage as proved for continued service it must be relubri S t w In Fig N l2 cated prior to re installation into the axle housing The Unit Bearing assembly can be hand packed 1 with grease on the axle shaft by the method out e fj lined below Lithium soap wheel bearing grease I Part No 998386 should be used to relubricate Unit in Bearing assembly r b Push seal away from bearing and fill the area 4 or cavity between the seal and bearing with the V recommended grease Refer to Fig N 9 Ve iAV i c After the cavity is full of grease wrap tape YL m completely around the rib ring and seal to enclose the cavity as shown in Fig N 10 jjj W e V V T f V A ZE i I ik i i r eV i j I i r aw EIE rr W M 14395 iz is FIG N 12 APPLYING GREASE TO ROLLERS ag 2 E lf h U A A A Grease should also be applied to the inboard lin V e grease seal in the axle housing and in the cavity V i w between the inboard rease seal and th bearin V g 9 g I e i V n Tlhe bottom one th1rd of this cavity should be filled 2 eleeee A with grease ti i gl Install the axle shaft and bearing assembly into x axle housing as described in Par N 8 This com pletes the serv1c1ng of the axle shaft Unit Bearing l 14208 rio N 10 A1 P1 Y1Nc TAPE To BEARING IN 7 Unit Bearing Removal AND SML If it is necessary to remove the Un it Bearing as s tbl f th zl h ft th ed tl d d With the tape in place push the seal upward ySh 1Td bg ii 1FO i1 G pmcl ure Ou me toward the bearing assembly forcing 1 he grease between the rollers and through the hearing as Zaaution Under no circumstances should axle shaft sembly make C ftam the beafliig 3SS mbly is retaining rings or bearings be removed using a packed completely full of grease Refer t0 Fig torch because heat fed into the axle shaft bearing N 1 journal weakens this area the axle shaft assembly in a heavy vise A gte Drill a 1 4 inch 6 35 mm hole in the outside e diameter of the retainer ring to a depth approxi z eneng n Aeenll n V ikle p mately 3 the thickness of the retainer ring DO i gl f V ge NOT drill all the way through the retainer ring 1 Q z ge l E C ll l S the drill could damage the axle shaft After V l r ilr iZ lir1g the retainer ring use a chisel positioned i z q across the drilled hole and cut a deep groove into e i the retainer ring This will enlarge bore of retainer T i z ring or split the ring and permit it to be driven off of the axle shaft Refer to Fig N 13 i i if lb Using a hacksaw cut through the oil seal being VH r car eful not to damage the seal contact surface ii lfiemove oil seal from axle shaft cr O lm l t Thoroughly iubricate VV 343 puller bolts and bolt contact points before attempting to remove M B lbearing from axle shaft DO NOT USE POWER 1 14399 OPERATED IMPACT TOOLS ON PULLER B Cl LTS FIG N ll FORCING GREASE INTO BEARING L 291

Next

Next