Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

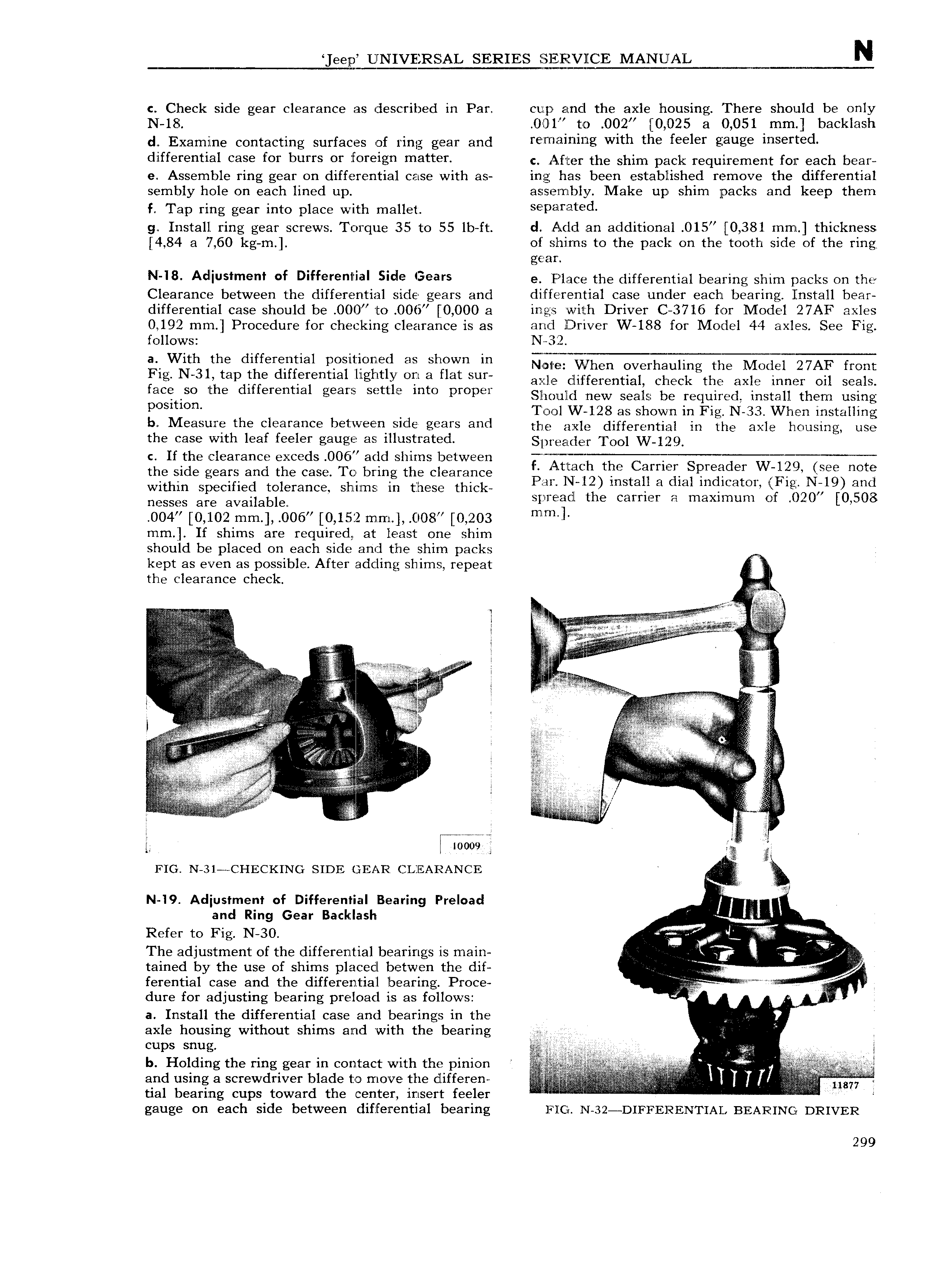

jeep UNIVEESAL SERIES MANUAL N c Check side gear clearance as described in Par cup and the axle housing I here should be only N 18 00l to 002 0 025 a 0 051 mm backlash d Examine contacting surfaces of ring gear and Y YVV tUml g with the f 1 Y 8Z8Ug inserted differe ti 1 case for burrs Or F r ig matter e After the shim pack requirement for each bear e Assemble ring gear on differential case with as ing has been established remove the differential sembly hole on each lined up assembly Make up shim packs and keep them f Tap ring gear into place with mallet F 8 Y Ht d g Install ring gear screws T rque 35 to 55 lb ft d Add an additional 015 0 381 mm thickness 4 84 a 7 60 kg m of shims to the pack on the tooth side of the ring gear N l8 Adllusimem f Differential Side Gears e F lace the differential bearing shim packs on the Clearance between the differential side gears and differential case under each bearing Install bear differential case should be 0 0 to 006 0 000 a ings with Driver C 3716 for Model 27AF axles 0 192 mm Procedure for checkin clearance is as ancl Driver W 188 for Model 44 axles See Fig g follows N 32 Wifi 1 1 6 d f a1 F i i as S f V m Nine W hen overhauling me Model 27AF nent flg Ltapdfffe I l nt1a iglt OQ a dt Sufi a l e differential check the axle inner oil seals ac SO it 8 1 Henna gearb Sem B mm propel Slhoulld new seals be required install them using P Teei W 128 as shown in Fig N 33 When installing b Measllf the clearance b i W ld gears and the axle differential in the axle housing use the case with leaf feeler gauge as illustrated 5 m e r TOO W jg9 c If the clearance exceds O06 add shims between f T the side gears and the case To bring the clearance tim Gini Pr id r W g 2i 1 Si HON within specified tolerance shiimsi in these thick dbh mst 3 A13 m 1C8tQI lk 1 9 3nf1 mass s are available spiea t e carrier ri maximum of 020 0 508 004 0 102 nini 006 0 15 2 mrn 008 0 203 mmf mm If shims are required at least one shim should be placed on each side and the shim packs kept as even as possible After adding shims repeat the clearance check i i Y l e it i ii 5 Q iti i i i F iiiii if i 2 ii i f t f i e Y I f X e A ifi l i i i i t iii A 1 i i 5 r et i i V i if iE e c iiicioiiii A FIG N 31 CHECKING SIDE GEAR1 CLEARANCE I x N 19 Adjustment of Differential Bearing Preload I i f and Ring Gear Backlash Refer to Fig N 2 0 e The adjustment of the differential bearings is main V tained by the use of shims placedl betwen the dif VV ferential case and the differential bearing Proce V J dure for adjusting bearing preload is as follows A a Install the differential case and bearings in the axle housing without shims and with the bearing wps S i er e i b Holding the ring gear in contact with the pinion and using a screwdriver blade to move the dliffererr lr T 7 I i i tial bearing cups toward the center insert feeler is i i i j i gauge on each side between diflferential bearing FIG I I 32 DIFI E12ENTIA1 BEARING DRIVER 299

Next

Next