Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

Prev

Next

Next

231156

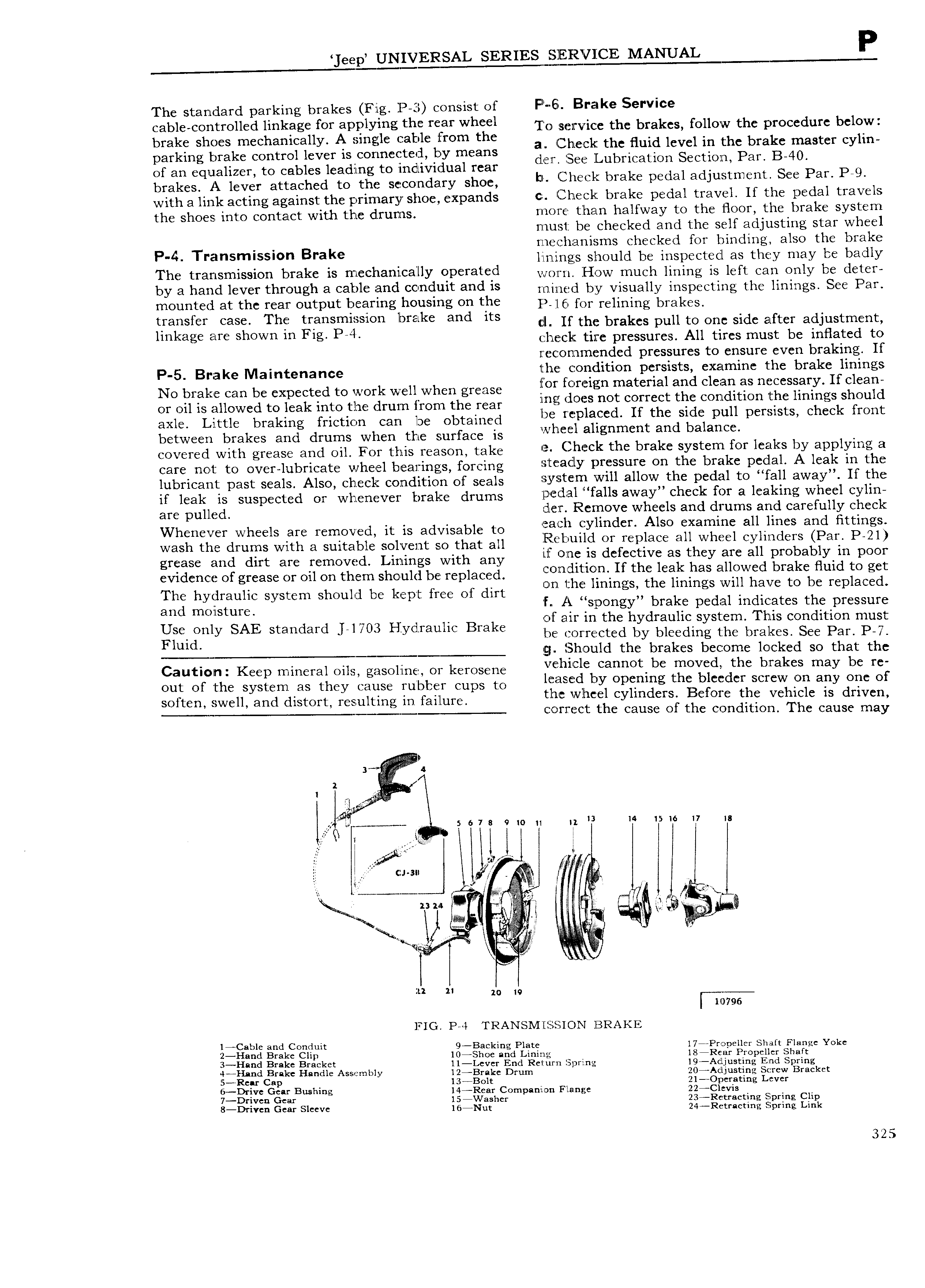

eep UNIVERSAL SERIES SlERVICE MANUAL P The standard parking brakes Fig P 3 consist of F 6 Brake Service abL CC trOu d k giifOfXpPly i g UE fflfif whiff To zservicce the brakes follow the procedure below ra e s oes mec amca y singge ea e rom e l parking brake control lever is connected by means ZLrlflglcfliefltgi L Oith al ggastcr Cylm of an equalizer to cables leading to individual rear l 6 n brakes A iavar attached to the secondary sim l h l brake pedal adiustmem Sec Par P 9 with a link acting against the prirnary shgci expands C ll hlecki brake pedal travel If the pedal travels the Shoes into Contact with the drums more than halfway to the Hoor the brake system must be checked and the self adjusting star wheel P 4 T B k meclianisms checked for binding also the brake rdnsrnlsslon ra e 4 linings should be inspected as they may be badly The transmission brake is n lechani cally operated Wnl n HOW much lining is left can Only be delay by 3 h3hd lever through 3 3hl 3hd Cohchht 3hd ls mined by visually inspecting the linings See Par mounted at the rear output bearing housing on the lg1 16 Ola nalining brnkee vmler me The Smi 5l ll l and its 1 ll rr the brakes pair to one side aaa adjustment linkage me Shown m Flg Phil 7 he cl tire pressures All tires must be inflated to reczlomrnended pressures to ensure even braking If P 5 Brake Maintenance lrlie condition persists examine the brake linings NO brake can be expected to Work Well when grease or foreign material and clean as necessary If clean or oil is allowed to leak into the drum from the rear jlngi laws not correct the Condition the hnmgs Should axle Little braking friction can be obtained the I p 1aF d If the Side pun p mlSts Check mnt between brakes and drums when the surface is Wheel l1g m t and bakm covered with grease and oil For this reason take C h k thc hY3k Systfim for l 3kS by 3PPlylh 3 care not to over lubricate wheel bearings forcing t 3 ly PYQSSUYC Oh the hY3k P di3l A l 3k lh th lubricant past seals Also check condition of seals t l 1 Wlh l1 w fh P d3l th f3l1 3W3y If the if leak is suspected or whenever brake drums d 3l Hf3h 3W3y h k OY 3 l 3kihg wheel yhh are pu1 ed der Remove wheels and drums and carefully check Vvnenever Wheels ere removed it is advisable re leaclx eylinder Also examine all lines and fittings wash the drums with a suitable solvent so that all E Cbul1 i Of replace an Wheel Cyfmders Pa PQI grease and dirt are removed Linings with any ll Ol fs dcfcctwc as they are au b bly m poor evidence of grease or oil on them should be replaced lm i m iJ If the leak has Elupwcd brake fluid tO get The hydraulic system should be kept free of dirt Irlliniglfii mmgS t1i li mng i11 1 lgihvc to if r pla C d and mOglSture slpongy ra e pe a in iczates t e pressure cf air in the h draulic s st em Thi d t t U l A y y l s con i ion mus Fishin y SAE Standard J 1703 Hydrauhc Brake be corrected by bleeding the brakes See Par P 7 T EI h 0Ulld the brakes become locked so that the Caution Keep mineral oils gasoline or kerosene lh l Cannohbc movcdi thc brakes may bc TC out of the system as they cause rubber cups to l mS d by Opgmng the bl d f SCYCW Ph 3hy Ohc Of SOl t n Swell and disrertl resulting in failure the wheel cylinders Before the vehicle is driven j C7Ol l C t the 231156 of the CO1 1d1ti0n The cause may e 4 1 l Q i r J 5 6 7 B Q lo ll liz I3 I4 I5 I6 I7 IB f ll l lea l i 4 is l av li lf cu an l ll Q l l ll i YL I Ei tl a 23 zu li l h w l Q l li VI ar r r r il i I iiii A i U Il 10 19 m Time FIG PV4 TRANSM i EL E 1ON BRAKE gggiifg l lgii 2El ill me gand Brake Handle Assembly l24Brake Drum c uml Oprbna ggi ijigiggket Pf Cap 13 B 1t 21 Operating Lever g x G fBuShlng lg4 tarhCompan lou Flange 224 Clevis l l r 8 Driven Gear Sleeve 164NSi cr 325

Next

Next