Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

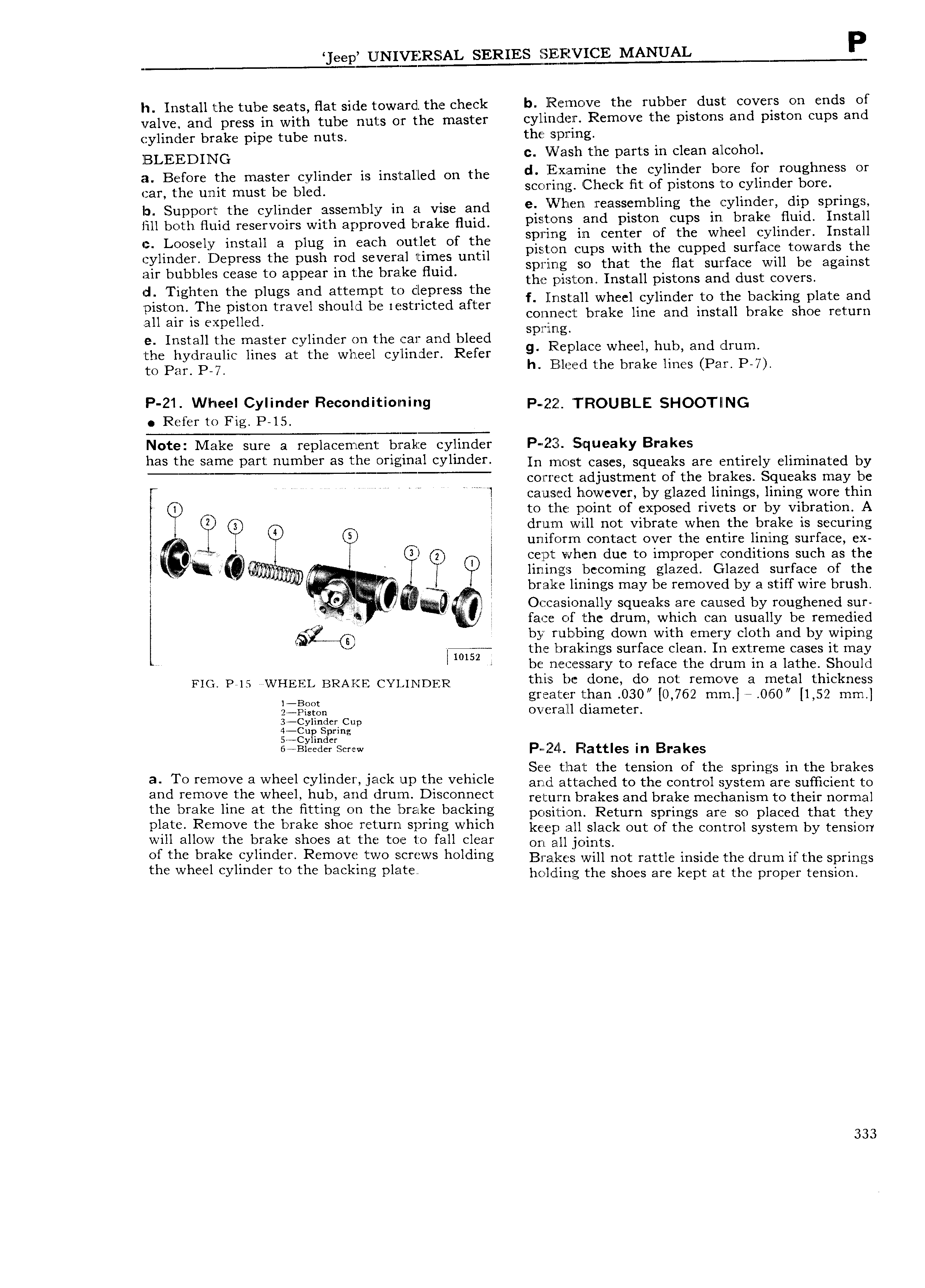

eep UNIVERSAL SERIES MANUAL R h Install the tube seats flat side toward the check b lRemc ve the rubber dust covers on ends of valve and press in with tube nuts or the master cylm ler Remove the pistons and piston cups and cylinder brake pipe tube nuts the 5f 3l71i 1g lean alcohol IBLEEDING c I Vash the parts mrc I I 5 it Il d th d Ecxlamirie the cylinder bore for roughness or rT3 IigrEm 1cm iS r Iizgldcr 1 ms a e On C scor iiiilg Check fit of pistons to cylinder bore l lo Support the cylinder assembly in a vise and e Wlhlenl reeeeeerbheg th y r e r Hdl 1 Sgrulgii lill both fluid reservoirs with approved brake fluid p f O S eee Tstfmf cg h ac iYHnE r Iggtgu li 1LzOS l msmutk pm indeach rfglligslinggfugilii Bxiviitcli tclie cupped surfagze towards the Ly m Cr pr SS E pus Y0 sevc spring so that the flat surface will be agamst grr rlgubflee ctilase Qto appegr m the bY3 kelHuld th thc I I t C III Install pistons and dust 0V Y ig ten t e p ugs an attempt to cepress e f msmu Wheel C A i ylmder to the backing plate and t ig 1 pE 3n travel Should be lcstuctlyd after co1 me t brake line and install brake shoe return spring e Install the master cylinder on the car and bleed I l D I the h draulic lines at the wheel cylinder Refer g Rcpl m whcch hLlb 3nd 1rum Y to PHL P 7 h lE lleed the brake lines Par P 7 P 21 Wheel Cylinder Reconditioining P 3g TRQUB E QQT N Refer to Fig P l5 Note Make sure a replacenigrit brake cylinder P 2El S queaky Brakes has the Same Daft number as lih Oflgimril Ylmd Y In most cases squeaks are entirely eliminated by correct adjustment of the brakes Squeaks may be I if I iiii cau s l however by glazed linings lining wore thin I to tlrie point of exposed rivets or by vibration A 2 0 I E drunti will not vibrate when the brake is securing 5 uniforrn contact over the entire lining surface ex r W 3l 2 1 cept when due to improper conditions such as the V E I g I lininegcs becoming glazed Glazed surface of the l k brake linings may be removed by a stiff wire brush ii i 9 A O r z2nsionally squeaks are caused by roughened sur i face of the drum which can usually be remedied 5 by rubbing down with emery cloth and by wiping i W the briakiings surface clean In extreme cases it may be n e es sary to reface the drum in a lathe Should FICL RIS WHEEL BRA E CY II1 IDER this be done do not remove a metal thickness l B Ot greater than 030 0 762 mm 0 60 1 52 mm 2 r teri overall diameter i d r e I 6 B1eeder Screw P iZ ll Flattles lh Brakes See tl t th t fthe r th b ke e Te rereeve e wheel ey1i der ierek up the vehiele and affleteiieti tg leegtreiiiyiliehligarensutiieiegilt errd rerrrerve the wheel hee and drum Dieeenneet rettrm brakes and hrake mechanism to their normal the bYak him et th Httmg OU th lbmkf b3 k g pc sition Return springs are so placed that they plate Remove the brake shoe return spring which keep Hu Slack Out Of the COIIU OI System by tensicm will allow the brake shoes at the toe to fall clear OH an jC IntS ef the brake eyheder Remeve twe eerews heldmg Brakes will riet rattle inside the drum if the springs the Wheel eylmder te the beekmg piertet h lding the shoes are kept at the proper tension 3 33

Next

Next