Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

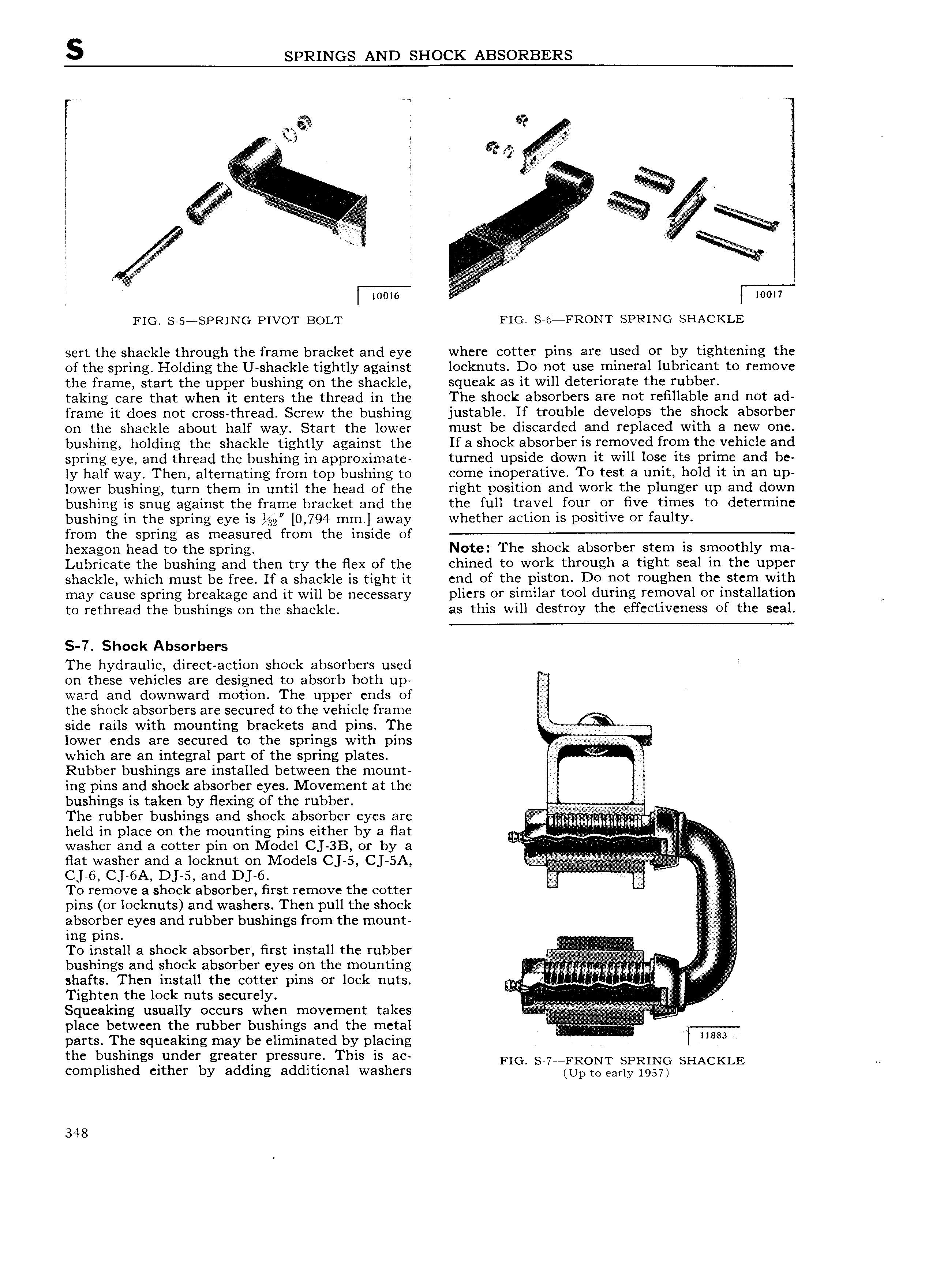

S SPRINGS AND SHOCK ABSORBERS fr ki VV in Q VV T g f l I 1 Z V l V 5 I L V X i Q E l I 10016 l noon FIG S 5 SPRING PIVOT BOLT FIG S 6 FRONT SPRING SHACKLE sert the shackle through the frame bracket and eye where cotter pins are used or by tightening the of the spring Holding the U shackle tightly against locknuts Do not use mineral lubricant to remove the frame start the upper bushing on the shackle squeak as it will deteriorate the rubber taking care that when it enters the thread in the The shock absorbers are not reiillable and not ad frame it does not cross thread Screw the bushing justable If trouble develops the shock absorber on the shackle about half way Start the lower must be discarded and replaced with a new one bushing holding the shackle tightly against the If a shock absorber is removed from the vehicle and spring eye and thread the bushing in approximate turned upside down it will lose its prime and be ly half way Then alternating from top bushing to come inoperative To test a unit hold it in an up lower bushing turn them in until the head of the right position and work the plunger up and down bushing is snug against the frame bracket and the the full travel four or five times to determine bushing in the spring eye is 2 0 794 mm away whether action is positive or faulty from the spring as measured from the inside of hexagon head to the spring Note The shock absorber stem is smoothly ma Lubricate the bushing and then try the Hex of the chined to work through a tight seal in the upper shackle which must be free If a shackle is tight it end of the piston Do not roughen the stem with may cause spring breakage and it will be necessary pliers or similar tool during removal or installation p to rethread the bushings on the shackle as this will destroy the effectiveness of the seal S 7 Shock Absorbers The hydraulic direct action shock absorbers used on these vehicles are designed to absorb both up ward and downward motion The upper ends of i the shock absorbers are secured to the vehicle frame side rails with mounting brackets and pins The lower ends are secured to the springs with pins which are an integral part of the spring plates Rubber bushings are installed between the mount ing pins and shock absorber eyes Movement at the bushings is taken by flexing of the rubber Mw 4 WY The rubber bushings and shock absorber eyes are Q held in place on the mounting pins either by a Hat e 5 I washer and a cotter pin on Model CJ 3B or by 3 q Aff E r fiat washer and a locknut on Models Cj 5 C SA To remove a shock absorber first remove the cotter pins or locknuts and washers Then pull the shock absorber eyes and rubber bushings from the mount 2 ing pins To install a shock absorber first install the rubber E bushings and shock absorber eyes on the mounting l shafts Then install the cotter pins or lock nuts 1 nr Tighten the lock nuts securely A Squeaking usually occurs when movement takes place between the rubber bushings and the metal parts The squeaking may be eliminated by placing i 11883 the bushings under greater pressure This is ac W complished either by adding additional washers FIG 5 7 i i21 I 5 gi SHACKLE W 348

Next

Next