Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

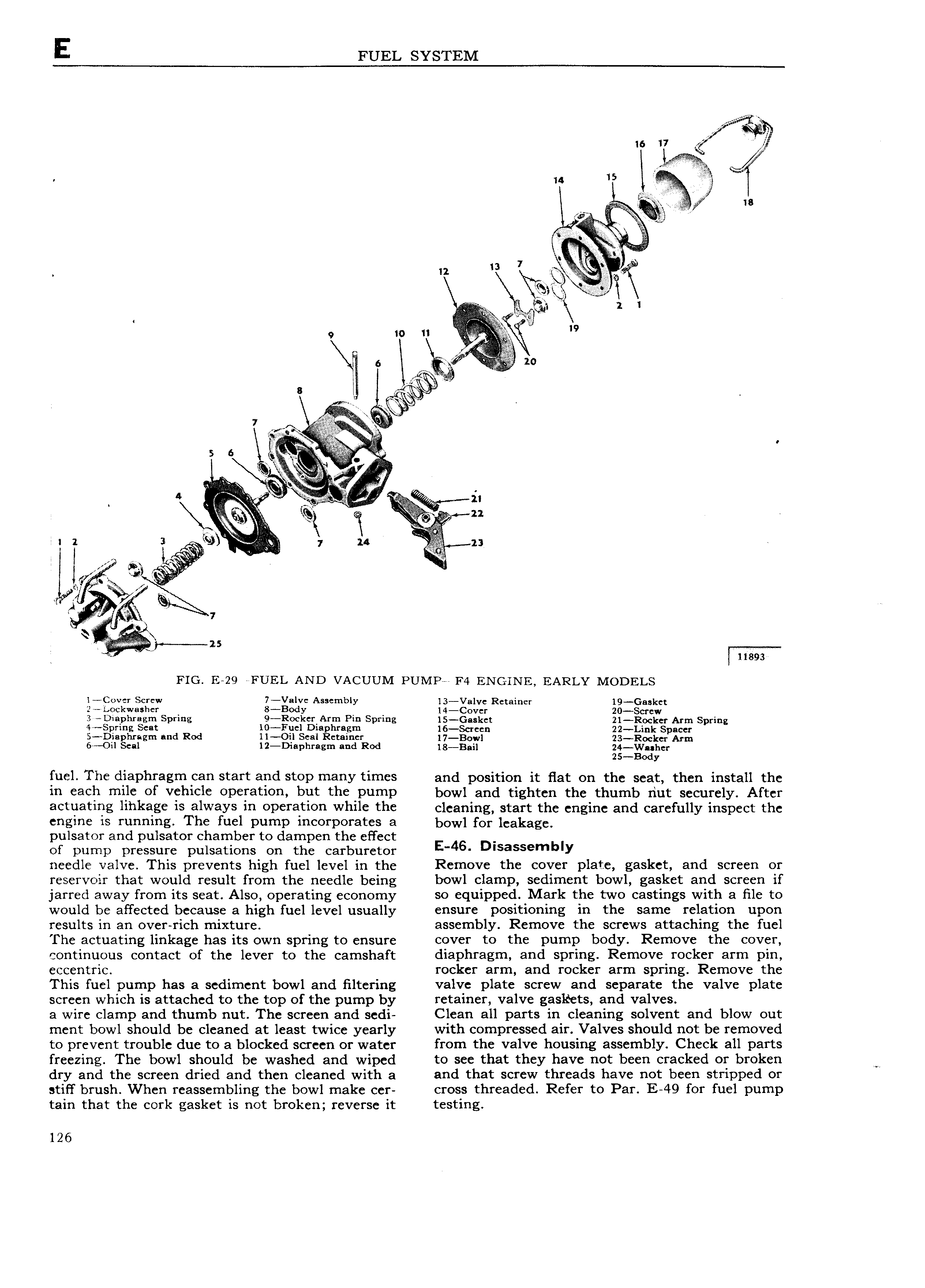

E FUEL SYSTEM A I E M E IZ 13 7 3 2 A f i 2 I 3 z v v VVV fl 2 ii s 9 10 11 V W v F 8 1 ii i U 1 5 6 li i 4 F i l I i Y1 il S Qi T A i T 3 i q 1 24 za A IV W S Vlv V M 2 5 I 11893 FIG E 29 VFUEL AND VACUUM PUMP F4 ENGINE EARLY MODELS 1 Cover Screw 7 Valve Assembly l3 Valve Retainer 19 Gasket Lockwasher V 8 B0dy l4 Cover 20 Screw 3 D a phragm Spring 9 Rocker Arm Pin Spring 15 Gasket 21 R0cker Arm Spring 47 Spring Seat l0 Fuel Diaphragm 16 Screen 22 Link Spacer 5 Diaphragm and Rod 11 011 Seal Retainer 17 Bowl 23 Rocker Arm 6 Oil Seal 12 Diaphragm and Rod 18 Bail 24 Wa her 25 B0dy fuel The diaphragm can start and stop many times and position it flat on the seat then install the in each mile of vehicle operation but the pump bowl and tighten the thumb nut securely After actuating linkage is always in operation while the cleaning start the engine and carefully inspect the engine is running The fuel pump incorporates a bowl for lgakagg pulsator and pulsator chamber to dampen the effect of pump pressure pulsations on the carburetor E 46 D as mb Y needle valve This prevents high fuel level in the Remove the cover plate gasket and screen or reservoir that would result from the needle being bowl clamp sediment bowl gasket and screen if jarred away from its seat Also operating economy so equipped Mark the two castings with a file to would be affected because a high fuel level usually ensure positioning in the same relation upon results in an over rich mixture assembly Remove the screws attaching the fuel The actuating linkage has its own spring to ensure cover to the pump body Remove the cover continuous contact of the lever to the camshaft diaphragm and spring Remove rocker arm pin eccentric rocker arm and rocker arm spring Remove the This fuel pump has a sediment bowl and filtering valve plate screw and separate the valve plate screen which is attached to the top of the pump by retainer valve gaskets and valves a wire clamp and thumb nut The screen and sedi Clean all parts in cleaning solvent and blow out ment bowl should be cleaned at least twice yearly with compressed air Valves should not be removed to prevent trouble due to a blocked screen or water from the valve housing assembly Check all parts freezing The bowl should be washed and wiped to see that they have not been cracked or broken dry and the screen dried and then cleaned with a and that screw threads have not been stripped or stiff brush When reassembling the bowl make cer cross threaded Refer to Par E 49 for fuel pump tain that the cork gasket is not broken reverse it testing 126

Next

Next