Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

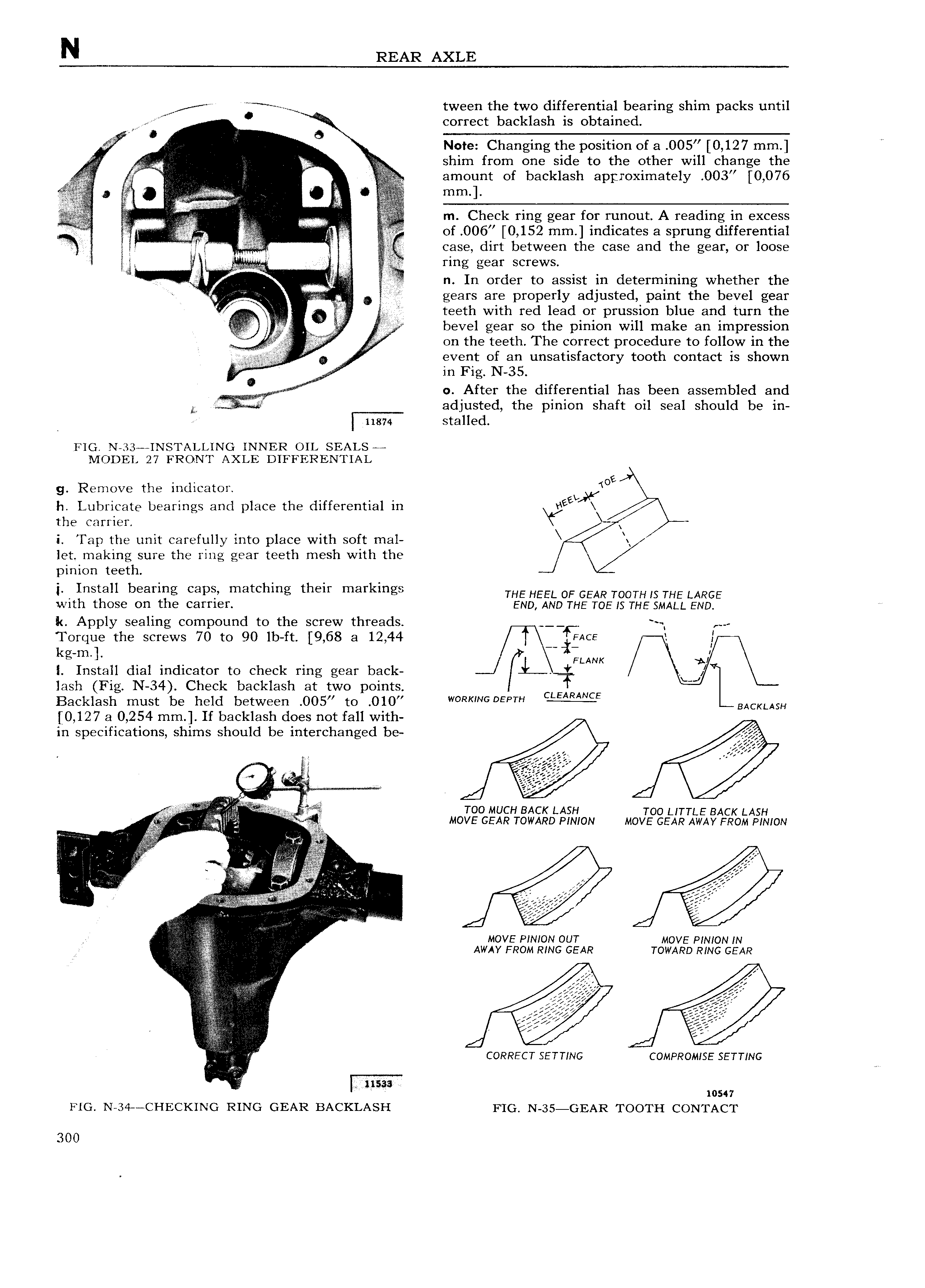

N REAR AXLE J tween tlze tg cgfferer tial bgaring shim packs until correct ac as is 0 tame 9 G Note Changing the position of a O05 0 127 mm Al A I shim from one side to the other will change the amount of backlash approximately 003 0 076 i T i Q mm I j I u I AJAA m Check ring gear for runout A reading in excess V of 006 0 152 mm indicates a sprung differential A T ii T i case dirt between the case and the gear or loose I E 3 ring gear screws 3 V i I I I U n In order to assist in determining whether the 1 4 I n t I I gears are properly adjusted paint the bevel gear Q it A teeth with red lead or prussion blue and turn the bevel gear so the pinion will make an impression T T i T V I on the teeth The correct procedure to follow in the V event of an unsatisfactory tooth contact is shown I Vr a in F1g N ss V I V V l 0 After the differential has been assembled and L adjusted the pinion shaft oil seal should be in 4 11874 stalled FIG N 33 INSTALLING INNER OIL SEALS MODEL 27 FRONT AXLE DIFFERENTIAL 2 g Remove the indicator 10 h Lubricate bearings and place the differential in We the carrier Y i Tap the unit carefully into place with soft mal let making sure the ring gear teeth mesh with the pinion teeth j Install bearing caps matching their markings THE HEEL OF GEAR TOOTH IS THE LARGE with those on the carrier END AND THE TOE IS THE SMALL END I R Apply sealing compound to the screw threads r Torque the screws 70 to 90 lb ft 9 68 a 12 44 ACE E i kg m T I FLANK ssl I Install dial indicator to check ring gear back J lash Fig N 34 Check backlash at two points CTEANC Backlash must be held between 005 to 010 RK GDEPT E BACKLASH 0 127 a 0 254 mm If backlash does not fall with in specifications shims should be interchanged be 2 577 J2 Q W TOO MUCH BACK LASH TOO LITTLE BACK LAgH MOVE GEAR TOWARD PINION MOVE GEAR AWAY FROM PINION af yl A X iiii i I ii A i I 1 ATAAT TTT ti jj r 4 4 I V I MOVE PINION OUT MOVE PINION IN AWAY FROM RING GEAR TOWARD RING GEAR V a2 I i i Z f CORRECT SETTING COMPROMISE SETTING usaa I 10547 FIG N 34 CHECKING RING GEAR BACKLASH FIG N 35 GEAR TOOTH CONTACT 300

Next

Next