Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

Prev

Next

Next

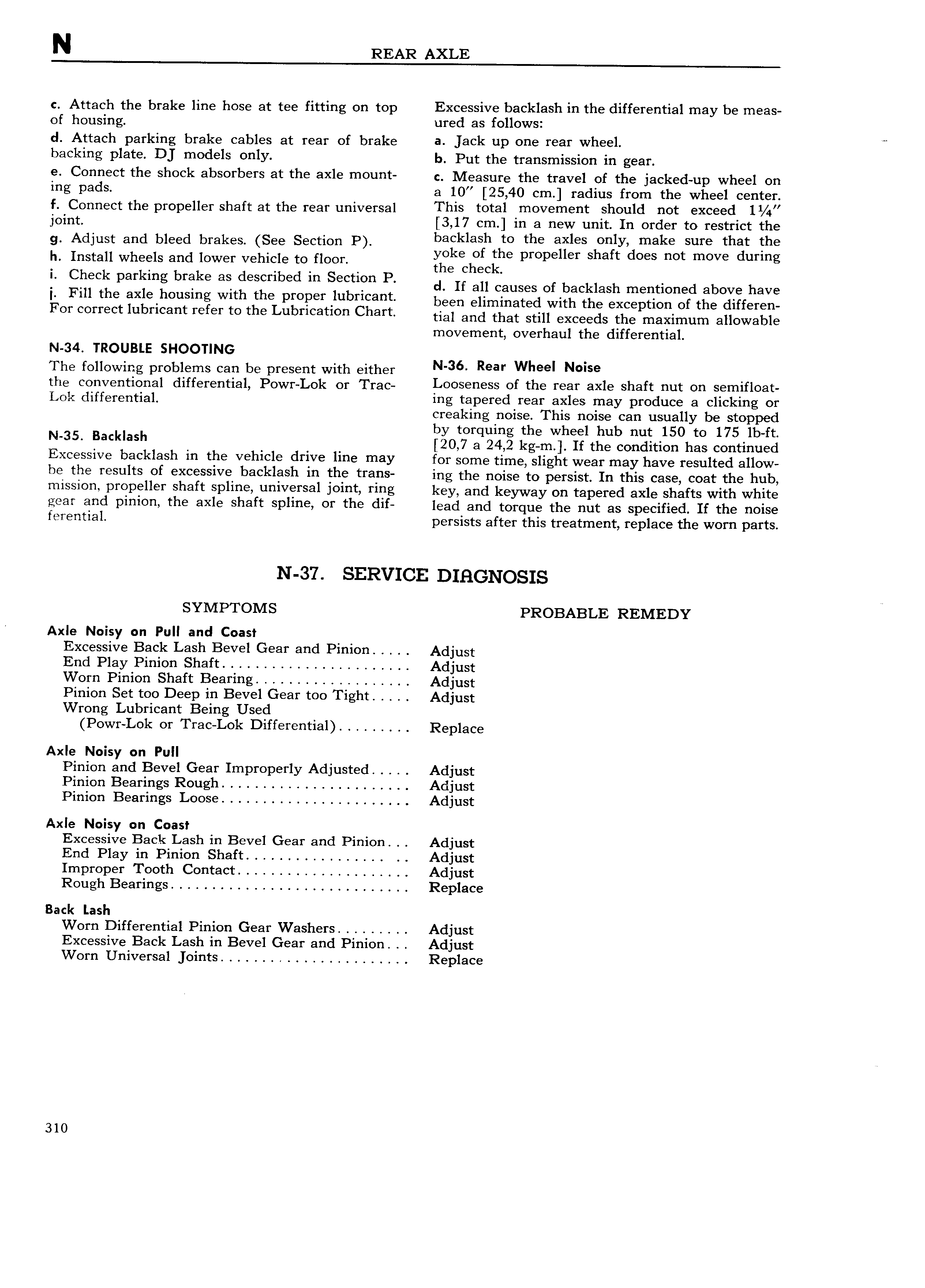

N REAR AXLE c Attach the brake line hose at tee fitting on top Excessive backlash in the differential may be meas of housing ured as follows d Attach parking brake cables at rear of brake B Jack up OHS f 8f wheel backing plate D models only b Put the transmission in gear e Connect the shock absorbers at the axle mount c Measure the travel of the jacked up wheel on ing Pads a 10 25 40 cm radius from the wheel center f Connect the propeller shaft at the rear universal ThiS7 total lmovement should not exceed 1 join 3 1 cm in a new unit In order to restrict the g Adjust and bleed brakes sae saandn P belikielb ge the elxiee e 1y meke Sure that the h Install wheels and lower vehicle to floor illge ilf cli 6 pmpe let Shaft does not move urmg Cbeeb pa k g beebe ee deeebbed be beeeeb P ai it all of backlash mentioned above have r Fm the eX1e be S s Web the Deeper 1 b ee t been eliminated with the exception ofthe dinaian For correct lubricant refer to the Lubrication Chart tial and that Still exceeds the maximum allowable movement overhaul the differential N 34 TROUBLE SHOOTING The following problems can be present with either N 36 Rear Wheel N e the conventional differential Powr Lok or Trac Lcoseness pf the rear axle shaftdnut on fer 1f1 at Ijgk diff l tja ing tapere rear ax es may pro uce a c IC mg or creaking noise This noise can usually be stopped by torquing the wheel hub nut 150 to 175 lb ft N 35 Beekleeb 20 7 a 24 2 kg m If the condition has continued Excessive backlash in the vehicle drive line may for some time slight wear may have resulted allow be the results of excessive backlash in the trans ing the noise to persist In this case coat the hub mission propeller shaft spline universal joint ring key and keyway on tapered axle shafts with white gear and pinion the axle shaft spline or the dif lead and torque the nut as specified If the noise ferential persists after this treatment replace the worn parts N 37 SERVICE DIHGNOSIS SYMPTOMS PROBABLE REMEDY L Axle Noisy on Pull and Coast Excessive Back Lash Bevel Gear and Pinion Adjust End Play Pinion Shaft Adjust Worn Pinion Shaft Bearing Adjust Pinion Set too Deep in Bevel Gear too Tight Adjust Wrong Lubricant Being Used Powr Lok or Trac Lok Differential Replace Axle Noisy on Pull Pinion and Bevel Gear Improperly Adjusted Adjust Pinion Bearings Rough Adjust Pinion Bearings Loose Adjust Axle Noisy on Coast Excessive Back Lash in Bevel Gear and Pinion Adjust End Play in Pinion Shaft Adjust Improper Tooth Contact Adjust Rough Bearings Replace Back Lash Worn Differential Pinion Gear Washers Adjust Excessive Back Lash in Bevel Gear and Pinion Adjust Worn Universal joints Replace 310

Next

Next