Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

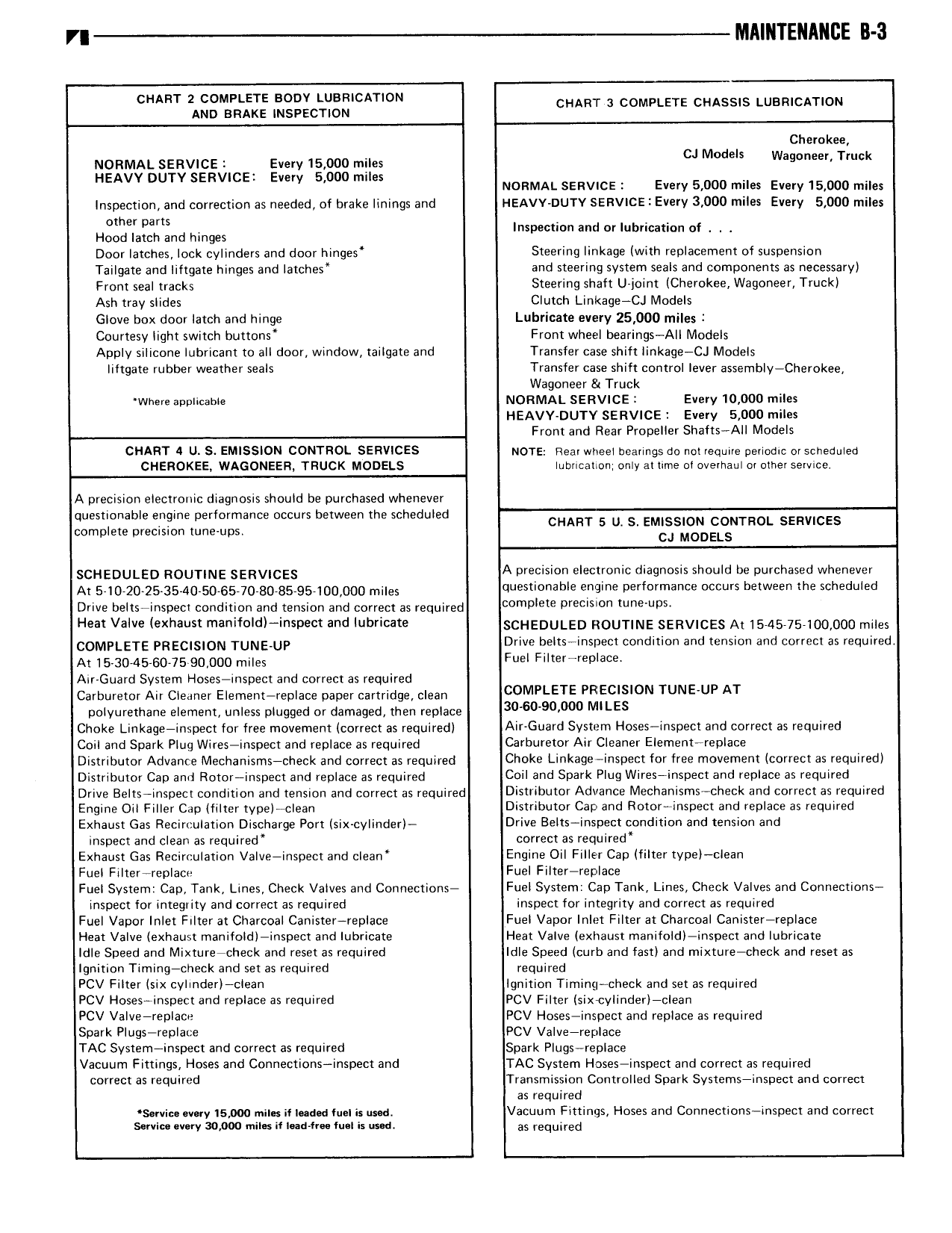

r MAINTENANCE B 3 CHART 2 ETE B T cnmr s corvrptere cmtssrs Luomcarrou AND BRAKE INSPECTION Cherokee Nonrvrm senvrc z Every 15 000 miles M d T HEAW DUTY E E E 5 uonmai serrvrcs Every 5 000 miles Every 15 000 miles Inspection and correction as needed of brake linings and NEAVV DU I V senvlcz Every 3 000 miles Every 5 000 miles H Z d hmges lnrpeeraerr and or rutsrreanerr or Door latches lock cylinders and door hrnges Steerrng linkage with replacement of suspension Tailgate and Irftgate hinges and Iatches and steering system seals and components as necessary Front seal tracks Steering shaft Urioint Cherokee Wagoneer Truck Ash tray slides Clutch Linkage CJ Models Glove box door latch and hinge Luhricate every 25 000 miles I Courtesy light switch buttons Front wheel bearings All Models Apply silicone lubricant to all door window tailgate and Transfer case shift linkage CJ Models Irltgate rubber weather seals Transfer case shift control lever assembly Cherokee Wagoneer Truck rwhere applreapie NORMAL SERVICE 1 Every 10 000 miles HEAVY DUTV SERVICE Every 5 000 miles Front and Rear Propeller Shafts All Models CHART 4 U S EMISSION CONTROL SERVICES NOTE Rear vvneel bearings do not require periodic or scnedrrled CHEROKEE WAGONEER TRUCK MODELS lubrication only at time or overrraul or otner service A precision electrornc diagnosis should be purchased whenever ggggz l i E EL b h cunt s u s emission courncr scnvrces CJ MODELS SCHEUULED ROUTINE SERVICES A precision electronic diagnosis should be purchased whenever Ay 5 0 20 25 g5 40 g0 65 y0 g0 85 g5 100 000 miles questionable engine performance occurs between the scheduled Drive belts inspect condition and tension and correct as required Eompiele D Heat Valve exhaust manifold inspect and Iubricate ggHEDu ED ROUTINE SERVICES Ay 15 45 75 r0g 00C mlm COMPLETE pg ECISION UNE Uy Drive belts inspect condition and tension and correct as requiredr At 15 3045r60 75 00 000 males Fuel Fii rsr l ArrrGuard System Hoses inspect and correct as required Carburetor Arr Clerrner Ererrrenr repiaee paper eartraage ereen COMPLETE EC 0N TUNEUP AT peryurernarre elerrrenr unless plugged or damaged then replace 3 9 V E cneke Linkage inspect for ree rrrevernenr correct as required Air Guard System Hoses inspect and correct as required Coil and Spark Plug Wires inspect and replace as required Carburetor Air Cleaner Element replace Distributor Advance Mechanisms check and correct as required Choke Linkage inspect for free movement correct as required Distributor Cap and Rotor inspect and replace as required Coil and Spark Plug Wires inspect and replace as required Drive Belts inspect condition and tension and correct as required Distributor Advance Mechanisms check and correct as required Engine Oil Filler Cap filter type clean Distributor Cap and Rotor inspect and replace as required Exhaust Gas Recirculation Discharge Port six cylinder Drive Belts inspect condition and tension and inspect and clean as required correct as required Exhaust Gas Recirculation Valve inspect and clean Engine Oil Filler Cap filter type clean Fuel Filter replace Fuel Filter replace Fuel System Cap Tank Lines Check Valves and Connections Fuel System Cap Tank Lines Check Valves and Connections inspect Ior integrity and correct as required inspect for integrity and correct as required Fuel Vapor Inlet Filter at Charcoal Canister replace Fuel Vapor Inlet Filter at Charcoal Canister replace Heat Valve exhaust manifold inspect and Iubricate Heat Valve exhaust manifold inspect and Iubricate Idle Speed and Mixture check and reset as required Idle Speed curb and fast and mixture check and reset as lgnrrron Timing check and set as required required POV Filter six cylinder clean Ignition Timing check and set as required POV Hoses inspect and replace as required PCV Filter lsixcylrnderl clean PCV Valve replace PCV Hoses inspect and replace as required Spark Plugs replace PCV Valve replace TAC System inspect and correct as required Spark Plugs replace Vacuum Fittings Hoses and Connections inspect and TAC System Hoses inspect and correct as required correct as required Transmission Controlled Spark Systems inspect and correct as required S rvic v 1y 15 000 mules il Ioadod fu I is und Vacuum Fittings Hoses and Connections lnspeC and correct Sarvioo y ry 30 000 miles il I d r fu I is used as mqulyed

Next

Next