Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

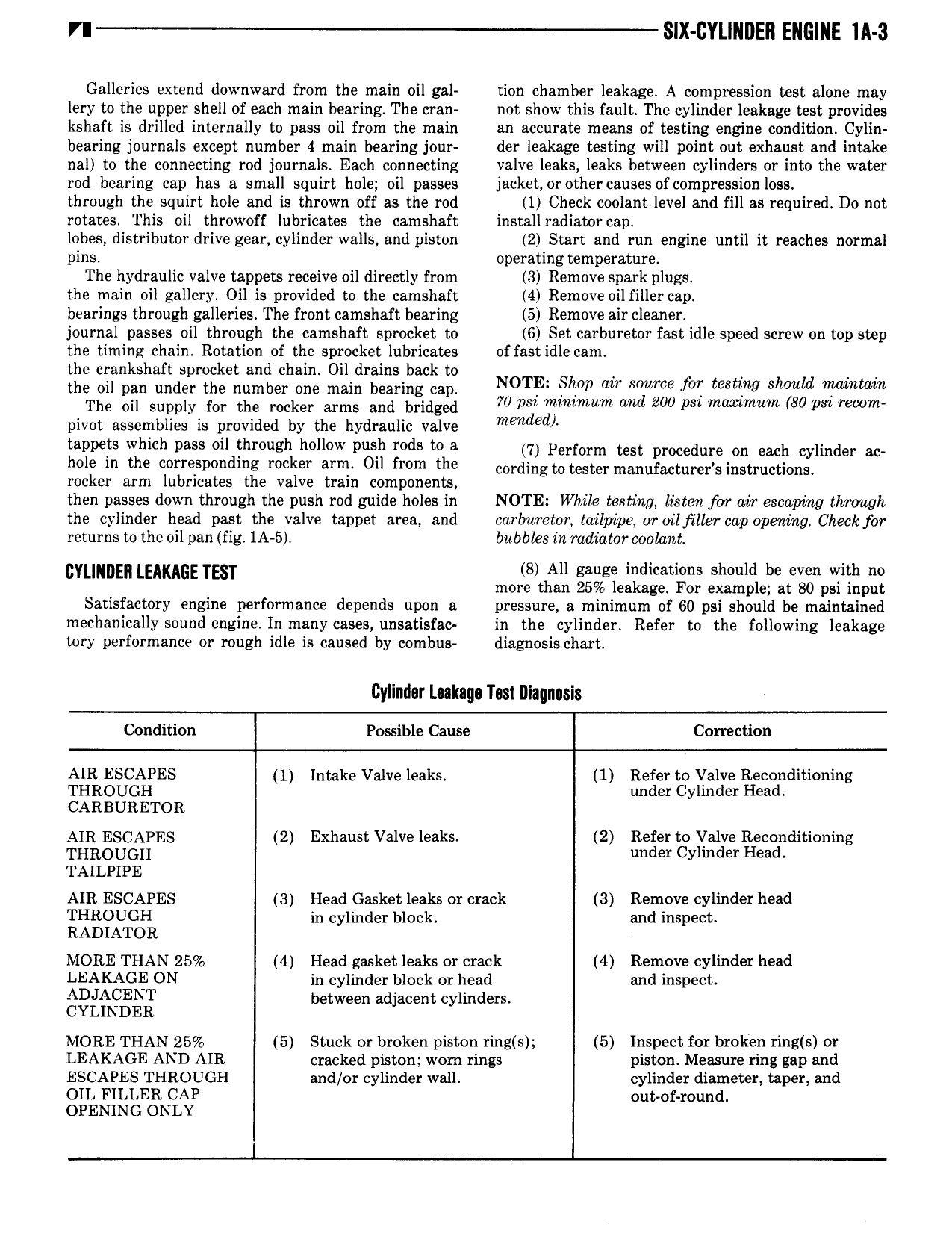

VI SIX CYLINDER ENGINE IA 3 Galleries extend downward from the main oil gal tion chamber leakage A compression test alone may lery to the upper shell of each main bearing The cran not show this fault The cylinder leakage test provides kshaft is drilled internally to pass oil from the main an accurate means of testing engine condition Cylin bearing journals except number 4 main bearing jour der leakage testing will point out exhaust and intake nal to the connecting rod journals Each co necting valve leaks leaks between cylinders or into the water rod bearing cap has a small squirt hole ol passes jacket orothercauses of compression loss through the squirt hole and is thrown off the rod 1 Check coolant level and fill as required Do not rotates This oil throwoff lubricates the amshaft install radiator cap lobes distributor drive gear cylinder walls and piston 2 Start and run engine until it reaches normal pins operating temperature The hydraulic valve tappets receive oil directly from 3 Remove spark plugs the main oil gallery Oil is provided to the camshaft 4 Remove oil fillercap bearings through galleries The front camshaft bearing 5 Remove air cleaner journal passes oil through the camshaft sprocket to 6 Set carburetor fast idle speed screw on top step the timing chain Rotation of the sprocket lubricates of fast idle cam the crankshaft sprocket and chain Oil drains back to the oil pan under the number one main bearing cap NOTE S fm tem shwld u rhd dd ddppiy dd the rocker arms ddd bridged 70 Pm mmimum mm 2001 5 mmmum 80 remem pivot assemblies is provided by the hydraulic valve mmdedl tappets which pass oil through hollow push rods to a 7 perform best procedure on each cylinder M hole in the corresponding rocker arm Oil from the cordingmwsm m mufacmm Sinm ucti0ns rocker arm lubricates the valve train components then passes down through the push rod guide holes in NOTE While testing listen for air escaping through the cylinder head past the valve tappet area and carburetor tailpipe orolljlller cap opening Checkfor returns to the oil pan fig 1A 5 bubbles in radiator coolant gyllupm LEAKAGE TEST 8 All gauge indications should be even with no more than 25 leakage For example at 80 psi input Satisfactory engine performance depends upon a pressure a minimum of 60 psi should be maintained mechanically sound engine In many cases unsatisfac in the cylinder Refer to the following leakage tory performance or rough idle is caused by combus diagnosis chart Cylinder Lukaga Tas Dlaqnusis Condition Possible Cause Correction AIR ESCAPES 1 Intake Valve leaks 1 Refer to Valve Reconditioning THROUGH under Cylinder Head CARBURETOR AIR ESCAPES 2 Exhaust Valve leaks 2 Refer to Valve Reconditioning THROUGH under Cylinder Head TAILPIPE AIR ESCAPES 3 Head Gasket leaks or crack 3 Remove cylinder head THROUGH in cylinder block and inspect RADIATOR MORE THAN 25 4 Head gasket leaks or crack 4 Remove cylinder head LEAKAGE ON in cylinder block or head and inspect ADJACENT between adjacent cylinders CYLINDER MORE THAN 25 5 Stuck or broken piston ring s 5 Inspect for broken ring s or LEAKAGE AND AIR cracked piston worn rings piston Measure ring gap and ESCAPES THROUGH and or cylinder wall cylinder diameter taper and OIL FILLER CAP out of round OPENING ONLY

Next

Next