Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

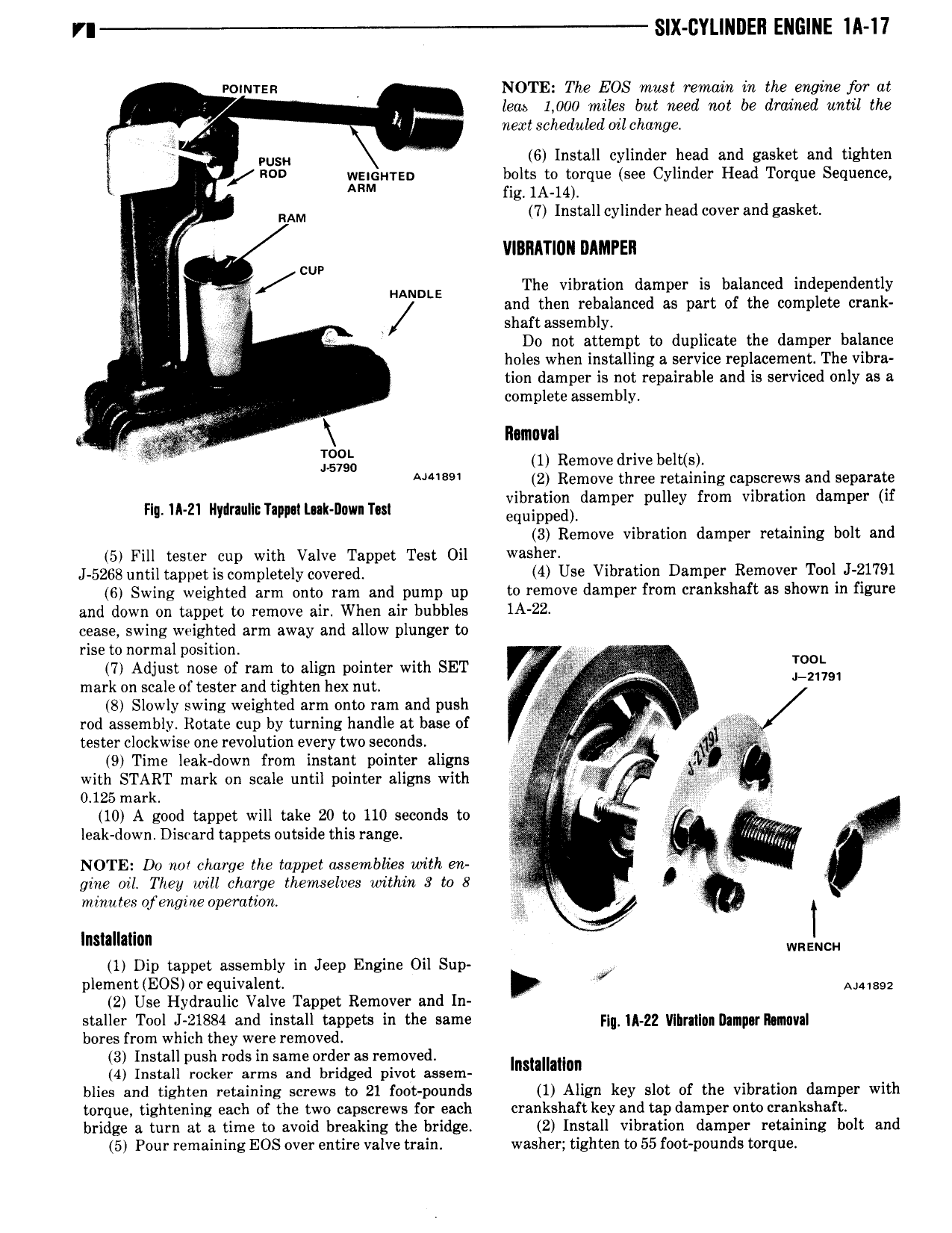

SIX CYL NllE l ENGINE lll 17 Pomrzn NOTE The EOS must remain in the engine for at leas 1 000 miles but need not be drained until the I L next scheduled oil change S PUSH 6 Install cylinder head and gasket and tighten V non welqurgp bolts to torque see Cylinder Head Torque Sequence O ARM fig 1A 14 l 0 RAM 7 Install cylinder head cover and gasket l VIIINITIUN DNMFEN T cur j my HANDLE The vibration damper is balanced independently ii 2 and then rebalanced as part of the complete crank I shaft assembly ll Q Do not attempt to duplicate the damper balance u holes when installing a service replacement The vibra I tion damper is not repairable and is serviced only as a complete assembly f r I E r Removal A IES 1 Remove drive belt s 9 2 Remove three retaining capscrews and separate H WZ y c1 Fmmk n w T I lb1i a t gg Vdamper pulley from vibration damper if 3 Remove vibration damper retaining bolt and 5 Fill tester cup with Valve Tappet Test Oil W9 Sh l J 5268 until tappgtig completely c0vgro l 4 Use Vibration Damper Remover Tool J 21791 6 Swing weighted arm onto ram and pump up to remove damper from crankshaft as shown in figure and down on tappet to remove air When air bubbles IA 22 cease swing weighted arm away and allow plunger to rise to normal position H 7 Adjust nose of ram to align pointer with SET Iogljlm mark on scale of tester and tighten hex nut Q 8 Slowly swing weighted arm onto ram and push V rod assembly Rotate cup by turning handle at base of l MQ lit tester clockwise one revolution every two seconds Z ln 9 Time leak down from instant pointer aligns e ln T with START mark on scale until pointer aligns with lv V l I 0 125 mark 5 ii 10 A good tappet will take 20 to 110 seconds to ii V leak down Disrard tappets outside this range A I i NOTE Do not charge the tappet assemblies with en gine oil They will charge themselves within 3 to 8 minutes ofenm he operation l Installation WRENCH 1 Dip tappet assembly in Jeep Engine Oil Sup plement EOS or equivalent A 41892 2 Use Hydraulic Valve Tappet Remover and In staller Tool J 21884 and install tappets in the same F u 1 zz llllmllqg mmng lhmnygl bores from which they were removed 3 Install ush rods in same order as removed 4 instaiiprorker arms and bridged pivot mem blies and tighten retaining screws to 21 foot pounds 1 Align key slot of the vibration damper with torque tightening each of the two capscrews for each crankshaft key and tap damper onto crankshaft bridge a turn at a time to avoid breaking the bridge 2 Install vibration damper retaining bolt and 5 Pour remaining EOS over entire valve train washer tighten to 55 foot pounds torque

Next

Next