Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

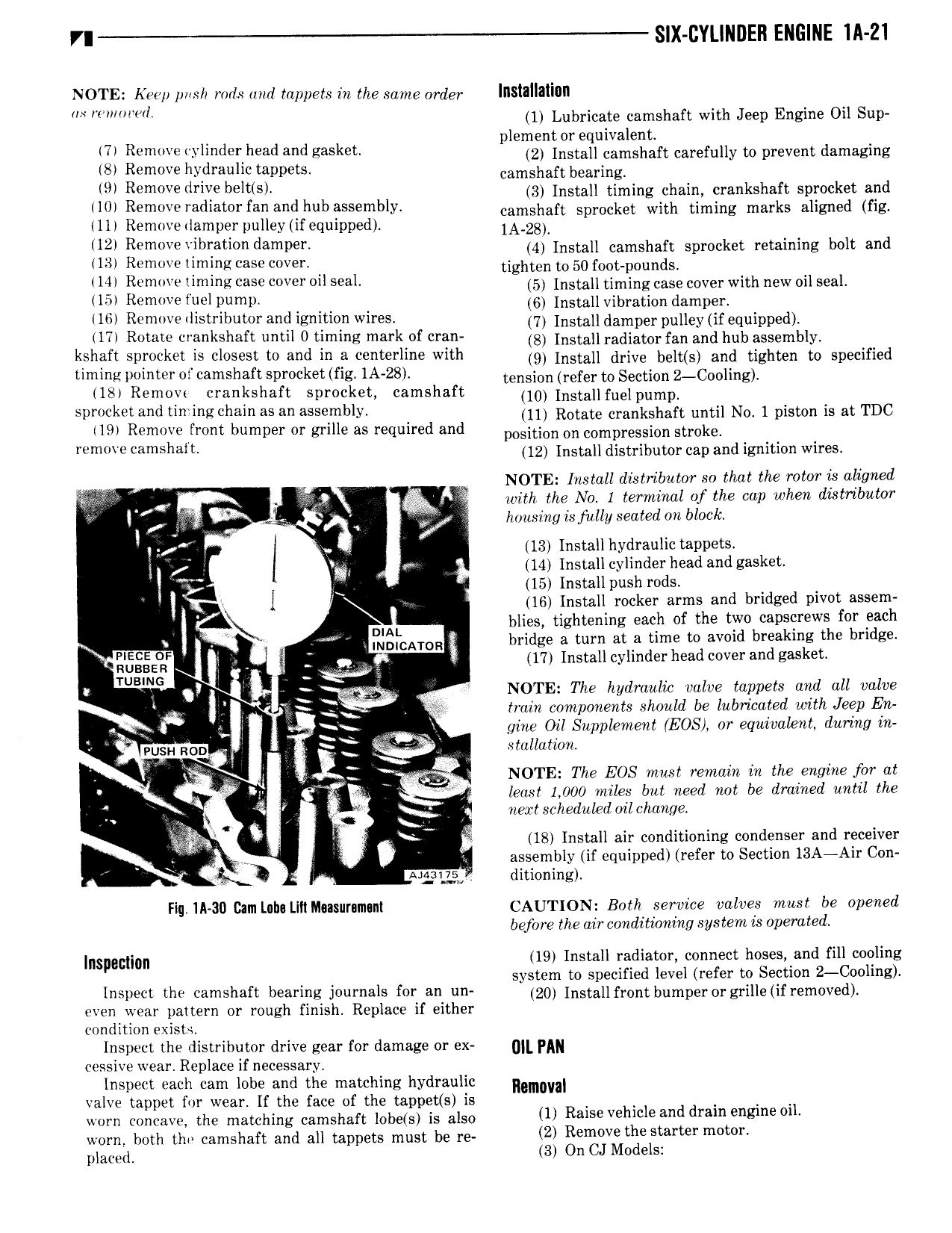

VI SIX CYLINDER ENGINE lA 21 NOTE Keep pus 1 rorls and lappets in the same order l ISllll3ll l I 1 Lnbeiente camshaft with Jeep Engine oii snp I V plement or equivalent ggmgg Itwrndeilihigd Mg gasket 2 Install camshaft carefully to prevent damaging I mu we camshaft bearing Eiggjg Srhleslelgisli dh b bl 3 Install timing chain crankshaft sprocket and 1 a ia or anan u assem y h ft kt th tr It I d 11 Removeilamperpulley ifequipped iirggs Spmc 8 Wl lmmg mar S mgm lg EZQEWE Ivfgxzgon damp 4 Install camshaft sprocket retaining bolt and We case mv tighten to 50f0ot pounds rise v r ml s al 5 Install timing case cover with new oil seal 6 1 t ll ii t ei 16 Remove distributor and ignition wires 27 I t Itg i r E uG equippedI 17 Rotate crankshaft until 0 timing mark of cran 8 Instau radiator fan and hub assembly l Sl ft SpY k tr S cloijesg to ang mf 9 m h with 9 Install drive beIt s and tighten to specified iming poin er oe cams a t sproc et ig IA 28 tension refer to Section 2 CO0ling 18 Removi crankshaft sprocket camshaft I0 lnSta IfueIpIIrrIp Sprocket and tiniing Cham as an assembly 11 Rotate crankshaft until No 1 piston is at TDC 19 Remove front bumper or grille as required and position on compression Str0k mmm 9 cemehr L 12 Install distributor cap and ignition wires I I V V L NOTE Install distributor so that the rotor is aligned V i t with the No 1 terminal of the cap when distributor e l Q housing isfully seated on block I lr i 13 Install hydraulic tappets I r wr 14 Install cylinder head and gasket I 15 Install push rods I 1 l I I 16 Install rocker arms and bridged pivot assem V DIAL blies tightening each of the two capscrews for each V I 1 M INDICATOR bridge a turn at a time to avoid breaking the bridge Piece RUBBER 2 R 17 Install cylinder head cover and gasket TUBING i I NOTE The hydraulic valve tappets and all valve I Y train components should be lubricated with Jeep En Iii g E Q 5 gine Oil Supplement EOS or equivalent during in Y pusy RO S slallaticnz I li I LZ T I NOTE The EOS mus remain in the engine for at V Q H t least 1 000 miles but need not be drained until the f ra neat scheduled oil change r I I if 18 Install air conditioning condenser and receiver assembly if equipped refer to Section 13A Air Con ik I A 51 V ditioning Fiq lA 30 Dam Luholllt Mclsltrnmcnl CAUTION Both service valves mus be opened bejbre the ai r conditioning system is operated lngpggiign 19r Install radiator connect hoses and fill cooling I th h it b 1 f system to specified level refer to Section 2 Couling USPW Cams 8 m E J0u 5 0 an U 20 Inst llfrontb mperorgrille ifremoved oven wear pattern or rough finish Replace if either a u condition exists Inspect the distributor drive gear for damage or ex ml PAN cessive wear Replace if necessary Inspect each cam lobe and the matching hydraulic MIIIIIWI valve tappet for wear If the face of the tappet s is I worn concave ine matching camshaft labels is also 1 R S V h1 l dd si 1 worn both tho camshaft and all tappets must be re 2 Remmle the Starter m t I III I d 3 On CJ Models

Next

Next