Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

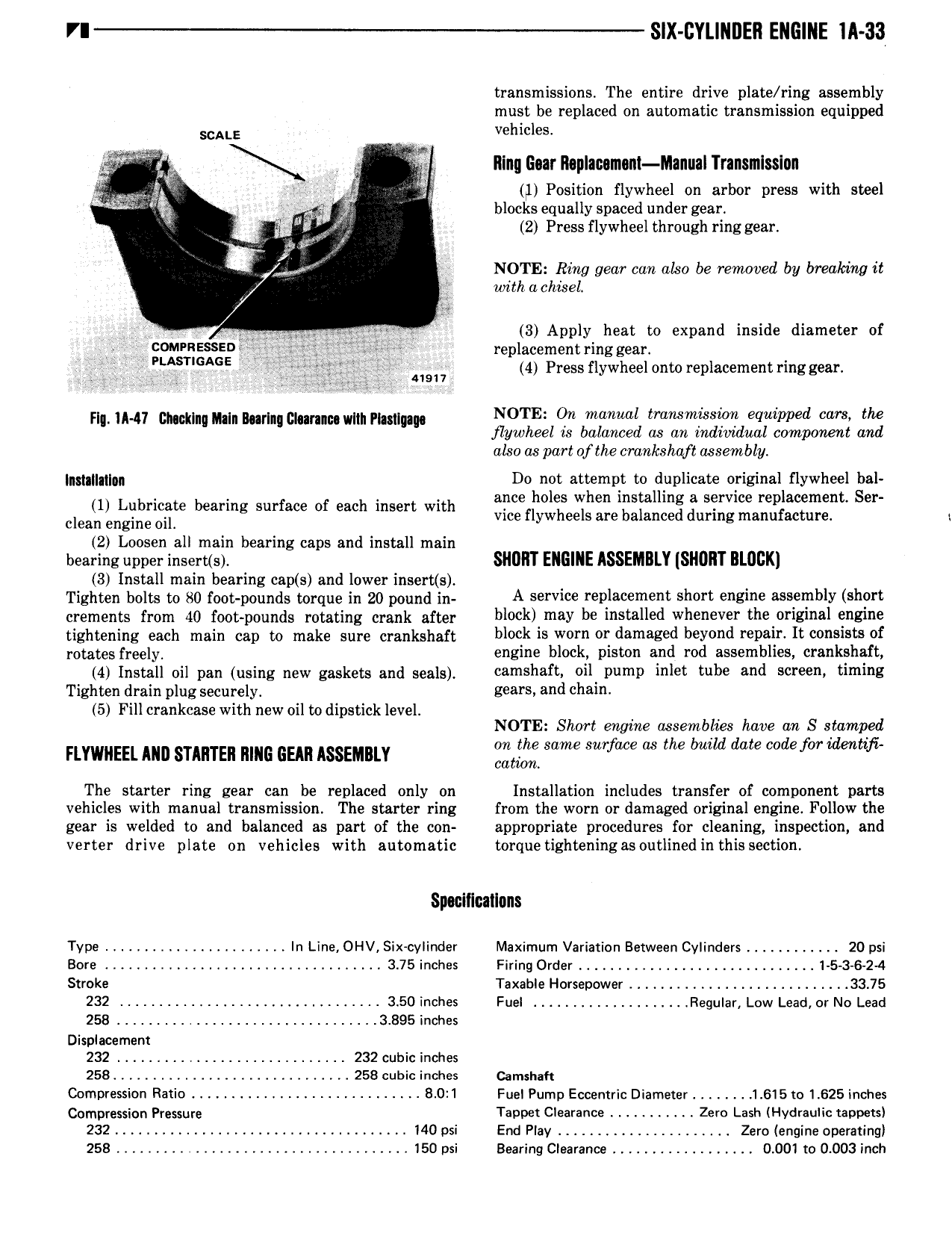

SIX CYLINDER ENGINE IA 33 transmissions The entire drive plate ring assembly must be replaced on automatic transmission equipped SCALE vehicles f t i A Illng lioar lloplaoomonl Manual Transmission l 4e V l A Position flywheel on arbor press with steel 2 gr I blocks equally spaced under gear e 2 Press flywheel through ring gear e 6 s if ele NOTE Ring gear can also be removed by breaking it mh orinscz W N g gf Y y M i 3 Apply heat to expand inside diameter of ssE replacement ring gear 9 jelTf sl A E gm 4 Press Hywheel onto replacement ring gear er 5 2 2 3 i fel a x a 3 1 n u 41 cnniiqmiiosmnunnrn oirirunipn N0TE Qu mem emeemeeiee eqeirved em the flywheel is balanced as an individual component and also as part ofthe crankshaft assembly lnmllgllgp Do not attempt to duplicate original flywheel bal rn r i iar bearing surface of each insert with eveegelf hen ge e gg ee e eme Ser clean Engine DHA vice yw ee s are a ance urmg manu acture 2 Loosen all main bearing caps and install main bearing upper inserds SNDNT ENGINE ASSEMBLY SNONT BLUBKI 3 Install main bearing cap s and lower insert s Tighten bolts to 80 foot pounds torque in 20 pound in A V replacement Snort Englne 855 nblY nnnrt crements from 40 foot pounds rotating crank after bl0 k F Y be n t ll d whenever n l lKln l nK n tightening each main cap to make sure crankshaft block IS Wnrn OT damaged beyond 9P8n It cdnslsw of rotate freely engine block piston and rod assemblies crankshaft 4 Install oil pan using new gaskets and seals camshaft 0ll Pump inlet tube and screen timinz Tighten drain plug securely 8981 and chain 5 Fill crankcase with new oil to dipstick level NOTE Short engine assemblies have an S stamped th lh bold d t il iklenti FLYWNEELNNII srmen NINE ono ASSEMBLY Qfmf f e Q The starter ring gear can be replaced only on Installation includes transfer of component parts vehicles with manual transmission The starter ring from the worn or damaged original engine Follow the gear is welded to and balanced as part of the con appropriate procedures for cleaning inspection and verter drive plate on vehicles with automatic torque tightening as outlined in this section Spuiitioallons Type In Line OHV Six cylinder Maximum Variation Between Cylinders 20 psi Bore 3 75 inches Firing Order 1 5 3 6 24 Stroke Taxable Horsepower 33 75 232 3 50 inches Fuel Regular Low Lead or No Lead 258 3 895 inches Displacement 232 232 cubic inches 258 258 cubic incnes Camshaft Compression Raiio 8 0 1 Fuel Pump Eccentric Diameter 1 615 to 1 625 inches compression Pressure Tappet clearance Zero Lash 1 lyclrsuiic rappers 232 140 psi End Play Zero engine operating 258 150 psi Bearing Clearance 0 001 to 0 003 inch

Next

Next