Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

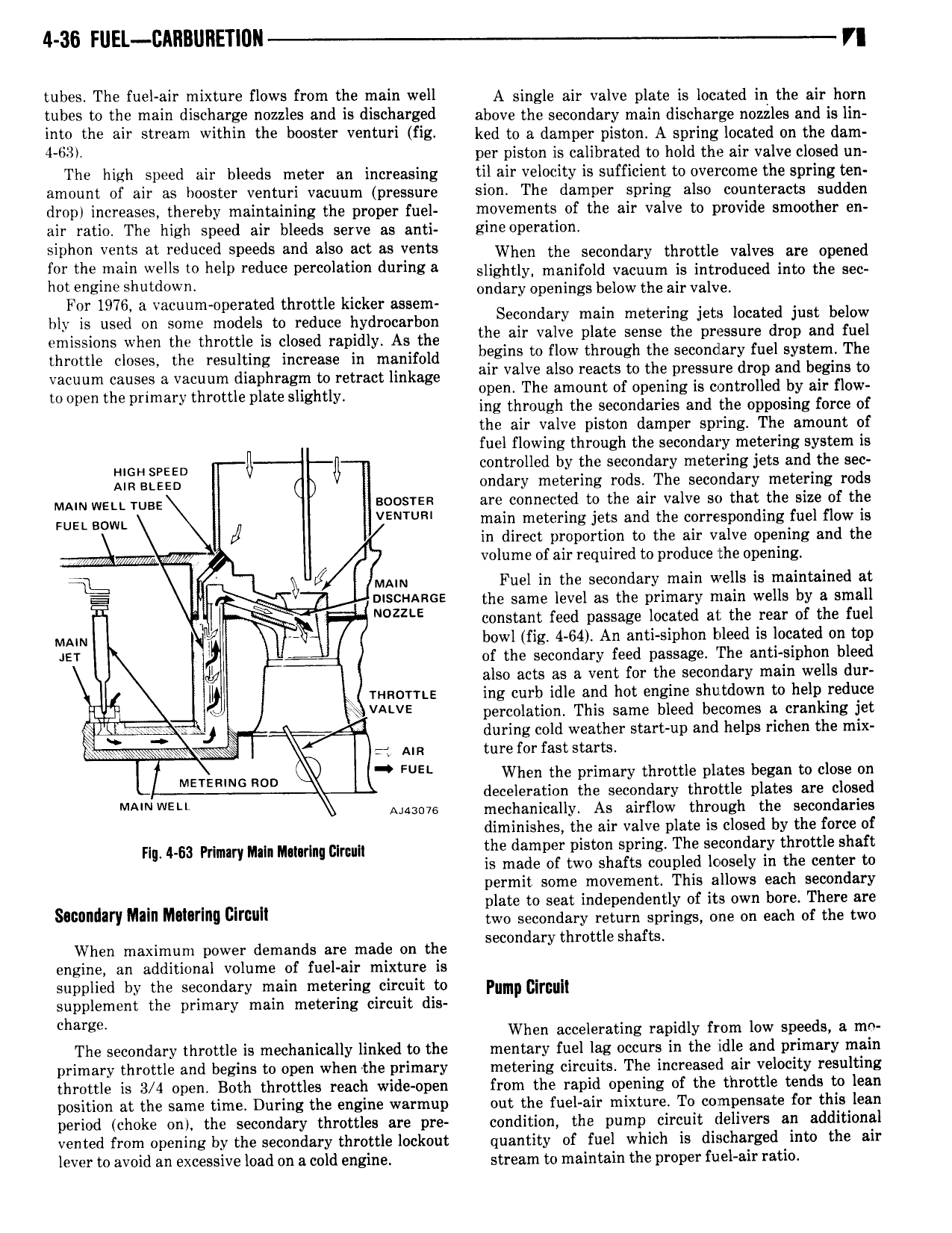

4 36 FllEL CMlB JRETl0N YI tubes The fuel air mixture flows from the main well A single air valve plate is located in the air horn tubes to the main discharge nozzles and is discharged above the secondary main discharge nozzles and is lin into the air stream within the booster venturi fig ked gg a damper piston A Spying located gn the dam 4 63 per piston is calibrated to hold the air valve closed un The high speed air bleeds meter an increasing til air velocity is sufficient to overcome the spring ten amount of air as booster venturi vacuum pressure sion The damper spring also counteracts sudden drop increases thereby maintaining the proper fuel m0Veme ef the ei valve tv P 0Vlde Smeether en air ratio The high speed air bleeds serve as anti Hineepefdtlenv Sllehen Ven 5 at Vedeeed Speeds and else eee ee Yente When the secondary throttle valves are opened for the main wells to help reduce percolation during a Slightly manifold vacuum is intmduced nm the sec het engine ShetdeWn ondary openings below the air valve For 1976 a vacuum operated throttle kicker assem bly is used on some models to reduce hydrocarbon Seqmdary mlam metering Jets Imatiid Just hetioili emissions when the throttle is closed rapidly As the thefm Valve D me Sense the pressure mp me ue urmoie closes the resorting increase an mrruu beans 0 ew emgh the v M1 y e 1 T vacuum causes a vacuum diaphragm to retract linkage 2 Xagl eaiigigitgftglglsiEgegmgggggii giglgigx w Open the primary thmme plate shghtly ing through the secondaries and the opposing force of the air valve piston damper spring The amount of fuel flowing through the secondary metering system is HIGH SPEED ll 8 cor trolled by the secgndrgly metergig jets aged the seg Amsuazo on ary metering ro s e secon ary me ring ro s MA WELL TUBE soosrza are connected to the air valve so that the size of the FUEL BOWL VENTUN main metering jets and the corresponding fuel flow is J in direct proportion to the air valve opening and the volume of air required to produce the opening 7 if Mann Fuel in the secondary main wells is maintained at V 0H RGE the same level as the primary main wells by a small zz E constant feed passage located at the rear of the fuel mam bowl fig 4 64 An anti siphon bleed is located on top Jer of the secondary feed passage The anti siphon bleed JZ also acts as a vent for the secondary main wells dur maornz ing curb idle and hot engine shutdown to help reduce EI VALVE percolation This same bleed becomes a cranking jet K J during cold weather start up and helps richen the mix mmmm d Am ture for fast starts Fuel M E R I d 2 L 12l fl h5li 5322 Zi ZiZ 2 WEU Auaovc mechanically As airflow through the secondaries diminishes the air valve plate is closed by the forceagf the damper piston spring The secondary throttle s t Hal 4 63 mm Mal Mmmm mmm is made of two shafts coupled loosely in the center to permit some movement This allows each secondary plate to seat independently of its own bore There are s m y Mlm Matmnq mmm two secondary return springs one on each of the two When maximum power demands are made on the secondary throttle Shafts engine an additional volume of fuel air mixture is supplied by the secondary main metering circuit to pump ci u supplement the primary main metering circuit dis charge When accelerating rapidly from low speeds a mn The secondary throttle is mechanically linked to the mentary fuel lag occurs in the idle and primary main primary throttle and begins to open when the primary metering circuits The increased air velocity resulting throttle is 3 4 open Both throttles reach wide open from the rapid opening of the throttle tends to lean position at the same time During the engine warmup out the fuel air mixture To compensate for this lean period choke on the secondary throttles are pre condition the pump circuit delivers an additional vented from opening by the secondary throttle lockout quantity of fuel which is discharged into the air lever to avoid an excessive load on a cold engine stream to maintain the proper fuel air ratio

Next

Next