Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

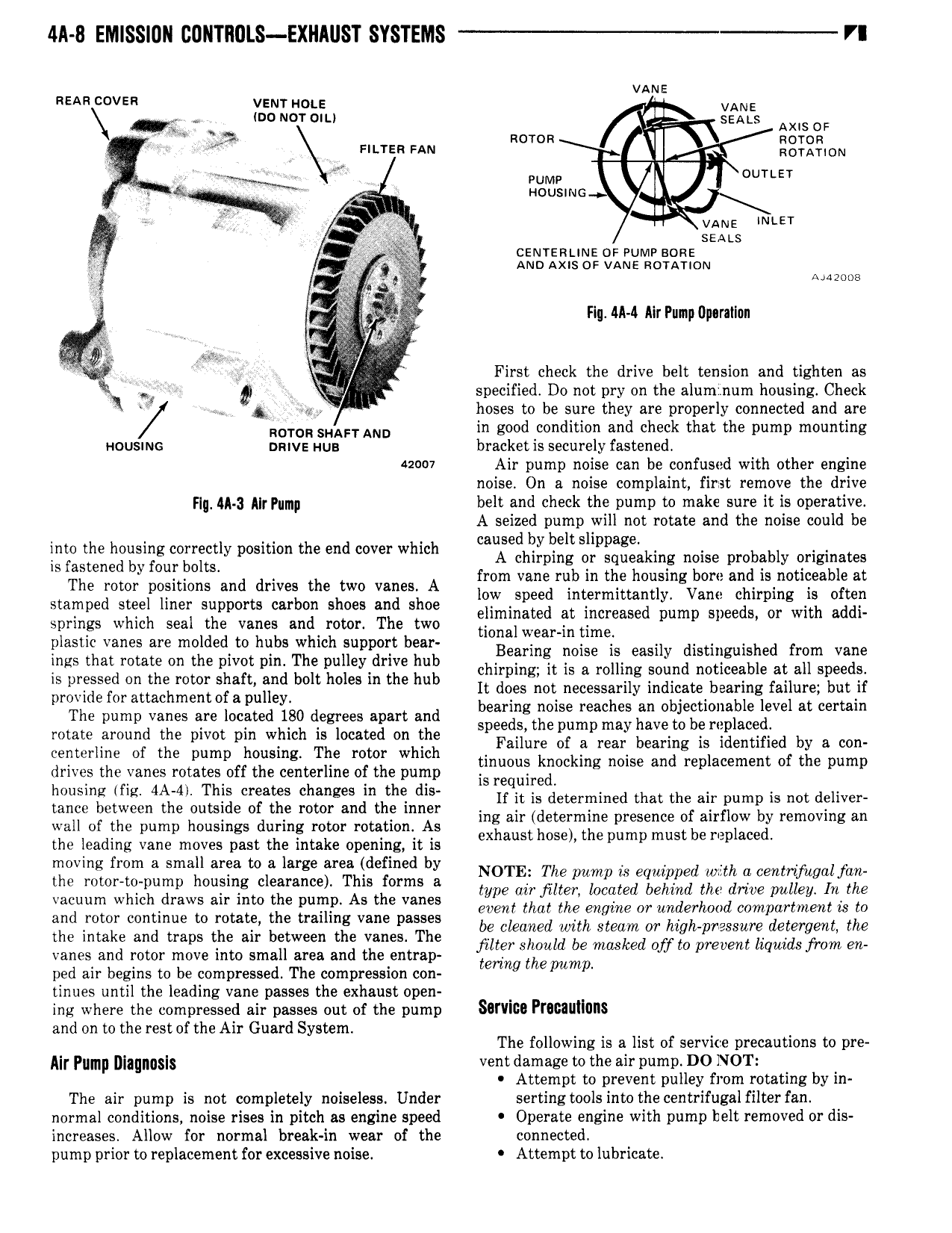

4Il 8 ENIISSIDN CONTll0LS EXl AUST SYSTEMS VI one coveu vsmr note WWE VANE loo moron seAts AXIS OF Q i KOTOR soton Q 6 muse nu ROTAHON V r ourtzv r V b wmv nousmo xv L be V x Ama Nl ET Q seats sept cemrentnme or now sons ey I kai Amo Axis or vane noraricrv M A lie te Fnqbu 4 Air Pump opmllun 3rb E f First check the drive belt tension and tighten as gf Q V 2 specified Do not pry on the alumtnum housing Check X bb g we hoses to be sure they are properly connected and are 0mRSHAF1 AND in good condition and check that the pump mounting HOUSING Dmvs nun bracket is securely fastened nom Air pump noise can be confused with other engine noise On a noise complaint first remove the drive F g M 3 Mr Pump belt and check the pump to make sure it is operative A seized pump will not rotate and the noise could be caused by belt slippage g g gg S gu g y me end com Wm A bbbbbbb bb bbbbbbbbb bbbb bbbbbbb bbbbbbbb y from vane rub in the housing bore and is noticeable at The rotor positions and drives the two V8 A IOW Speed mermmanqy vane chirping is often raced me lim S Ms rd bbmbbbbb bb bbbbbbbbb bbbb bbbbbb bb with bbbb springs which seal the vanes and rotor The two tionalwemnin time plastic vanes are molded to hubs which support bear Beam mise is easily distinguished from vane ings that rotate on the pivot pm The pulley drive hub chirpinggt is a rolling sound noticeable at all speeds gggggggjrogtggghgggggygfmgg bon hole in me b It bbbb bb bbbbbbbbby rbbbbbb bbbbbb rbbbbbb but ir The Pump as lmed 1 l me Md Z Z ZgriZ Eb T lZS ZZbZib Z ZZ biiVel rotate around the pivot pm which is located on the Failzmz of 3 rear bearin is identified by 3 com miterline Of the pump housing The mer which tinuous knocking noise and Eeplacement of the pump drives the vanes rotates off the centerline of the pump is required g S j ge 4 cg cigegs hj gw dc rr bb is bbbbbbbbbb that the bb bbmb is bbb dbbbbb ance Q een 9 Ou Sl Q 0 F m or an F mner ing air determine presence of airflow hy removing an wall of the pump housings during rotor rotation As exhaust hose the um mustbe rpplaced the leading vane moves past the intake opening it is p p moving from a small area to a large area defined by V the rotor to pump housing clearance This forms a Fogel umlggdelggigizdtzxt r e ZC g nf e irglmg W i d W5 algigw gf gy M me rem biibb bbbb bb bb bbbbbbbbb bbbbbbbbbblbb bb bb if 1 mndulue O S a F b i al 1 5 vane Pais be ckaued with steam or high pressure detergent the e m a B an raps B an e Ween B wmes e filler should be masked off to prevent liquids from en vanes and rotor move into small area and the entrap temlg the pump ped air begins to be compressed The compression con tinues until the leading vane passes the exhaust open ing where the compressed air passes out of the pump 0 VI6l Pl 00BlIll0IlS and on to the rest of the Air Guard System The following is a list of service precautions to pre Air Plllllp Dlannasls vent damage to the air pump DO NOT V Attempt to prevent pulley from rotating by in The air pump is not completely noiseless Under sertingtools into the centrifugal filterfan normal conditions noise rises in pitch as engine speed Operate engine with pump belt removed or dis increases Allow for normal break in wear of the connected pump prior to replacement for excessive noise Attempt to lubricate

Next

Next