Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

3219052

7050471

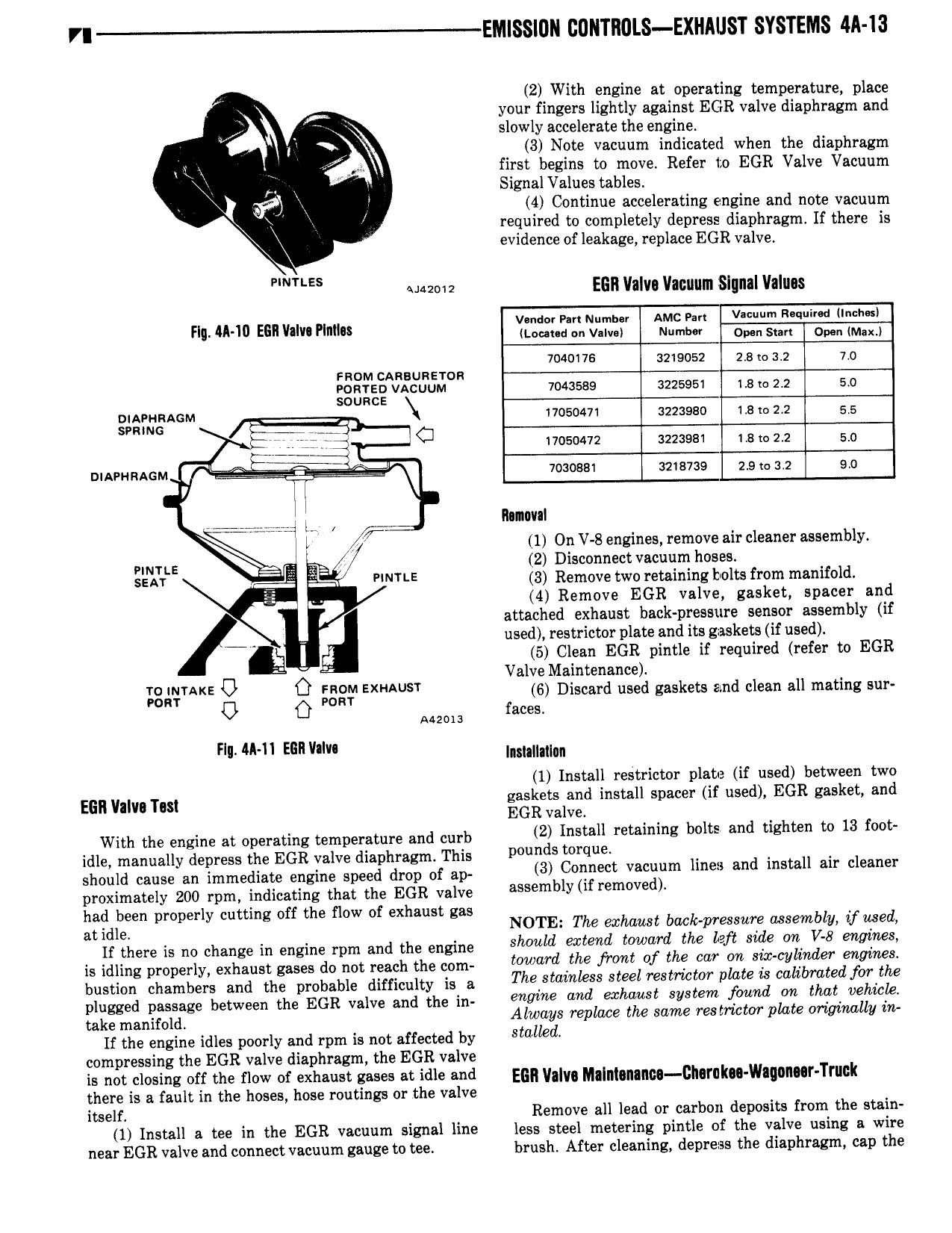

VI EM SSll N GUNTIIGLS EXHl UST SYSTEMS 4A 13 2 With engine at operating temperature place your fingers lightly against EGR valve diaphragm and slowly accelerate the engine p 3 Note vacuum indicated when the diaphragm 7 first begins to move Refer lc EGR Valve Vacuum r l Signal Values tables 4 Continue accelerating engine and note vacuum required to completely depress diaphragm If there is evidence of leakage replace EGR valve slum EGR Valve Vacuum Slgnal Values V pt v R wa ti an l ng ul in eau v lv rlml L ZL Z f L Il lI lil i ZI 7o o11s 3219052 zsms 2 7 o eso c n m vE T5 l masses may is 0 2 souncs oaaensacm l7050471 szzasso 1 srs 2 2 B svmuc n CI G 5 1 DIAPHRAGM vosossl azisvzs za ta a 2 Y l are srs lr L 1 On V 8 engines remove air cleaner assembly rm1 i e R 2 Disconnect vacuum hoses SEAT NT E 3 Remove two retaining bolts from manifold s 4 Remove EGR valve gasket spacer and L attached exhaust back pressure sensor assembly if f used restrictor plate and its gaskets if used A I 5 Clean EGR pintle if required refer to EGR Valve Maintenance LSAQTAKE O O S32 EXHAUST 6 Discard used gaskets and clean all mating sur 0 O Anon faces Flu IA 11 Ellll V Iv mmlmn 1 Install restrictor plate if used between two EGR ya ns gaskets and install spacer if used EGR gasket and EGR valve With the engine at operating temperature and curb 2 Install retaining b l s and ughwn tu 13 f t idle manually depress the EGR valve diaphragm This pounds torque Should cause an immediate engine speed drop of ap 3 Connect vacuum lines and install air cleaner proximately 200 rpm indicating that the EGR valve a Ssmb y f m eu hdl 1 tt ffthfl t li t ailidleien proper y cu mg 0 Q Ow 0 ex aus gas NOTE The exhaust bwck pressure assembly tf assed If there is no change in engine rpm and the engine Should e e d m d me lm Slug V 8 mglwsl is idling properly exhaust gases do not reach the com foward Phe fm 0f th uu O nj Vll d enmneu bustion chambers and the probable difficulty is a The Stu L Steel mstnctor plum is calibrated f T th e plugged passage between the EGR valve and the in Meme and exhaust system found on that vehicle take manifold Always replace the same resmctor plate ongmally in If the engine idles poorly and rpm is not affected by SL ued compressing the EGR valve diaphragm the EGR valve is not closing off the flow of exhaust gases at idle and Em V y Ma mgmnM qr wqggM r 1 ru there is a fault in the hoses hose routings or the valve itself Remove all lead or carbon deposits from the stain 1 Install a tee in the EGR vacuum signal line less steel metering pintle of the valve using a wire near EGR valve and connect vacuum gauge to tee brush After cleaning depress the diaphragm cap the

Next

Next