Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

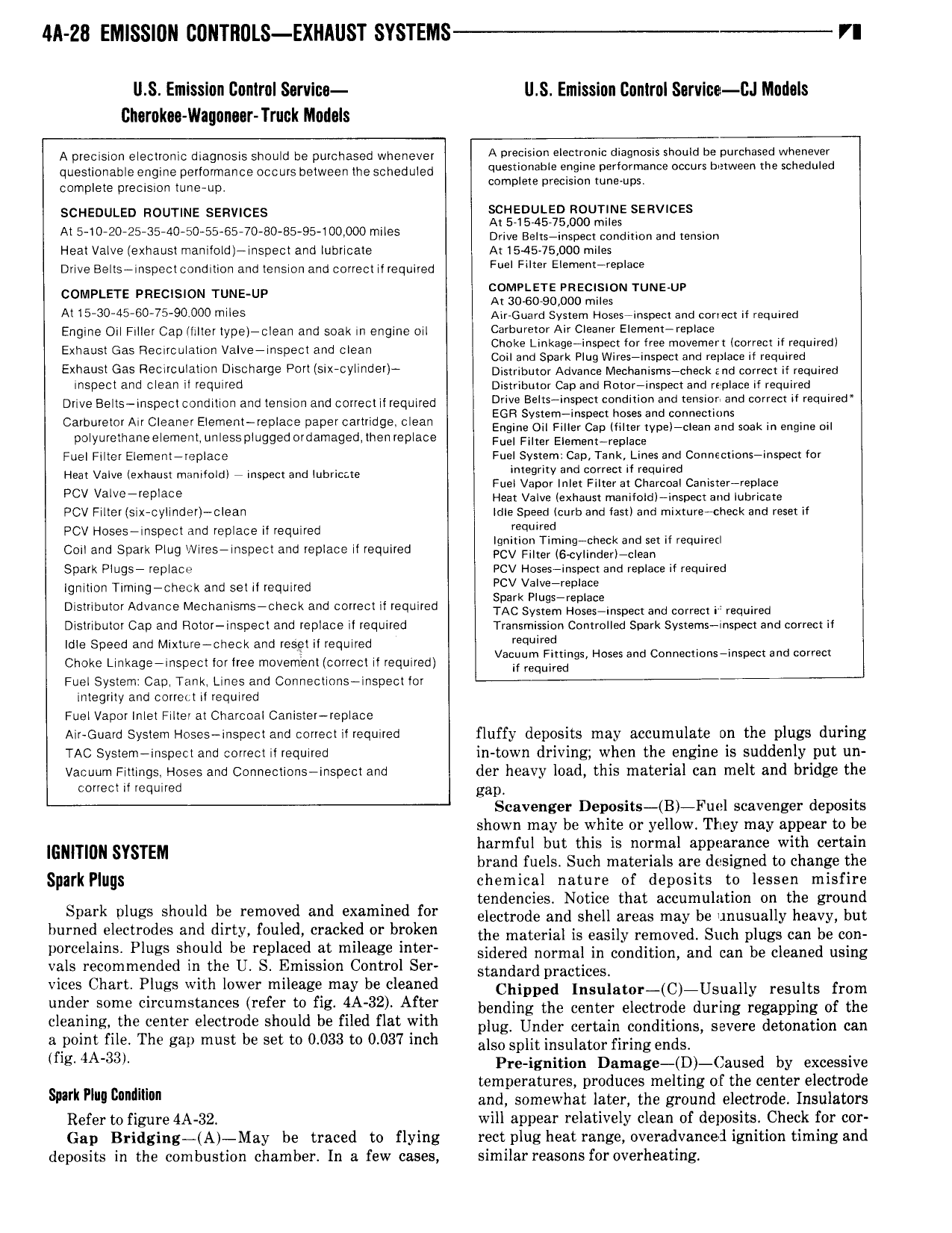

4ll 28 EMISSll Il COIlTlIOLS EXHAUST SYSTEMS 1 VI U S Emission Conlrol Service U S Emission Conlrol Service CJ Models Cherokee Wagoneer Truck Models A precision eleclronic diagnosis should be purchased whenever A precision electronic dlagnosrs should tn purchase wt r vrL questionable engine pertorrnance occurs berwearr me scheduled cruestlorrable enornelper orrnance occurs ttvveen r e se e u e SCHEDULED FIOUTINE SERVICES g U l IIl lsE SERVICES Al 5 I0 20 25 40 50 55 55 70 E0 85 95 l 00 000 miles Dm E Bgl s mspeu mndmon and mmlm Heal Valve lexhaust rnaniloldl lnspect and lubrlcale Ar15 45 75 000 miles me eerreernepeer me r e ere renererr ere correct rl requrree Fuel F r r r a comrters vnscisron Tune uv iffgzggg g rj f E U Al I5 30 45 50 75 90 000 lll Arr Guerra system rrasesarrspeer and correct rr requrreu Engine Oil Filler Cap llrller lype cIean and soak in engme orl Carburetor Arr Cleaner Element replace l Choke Linkage mspect for lree movamert correct r required E ha s Gas R l l Val F Sp and l cou and Spark Plug vvrresrrrrepeer and replace rr required Exhaust Gas Hecrrculalren Dlsonarcs Pwr ls rcvl r rl orerrrsuror Advance meehenremeeerreet erra correct rr required mspecl and clean ll required Distributor Cap and Hotorwnspect and replace il required Dru 9 B llS lnspecl cdrrdillon and lensron and correct rl requlreq l2g sg l lr1SD2 llvllldltion and tensitrrr and correct I requrred O A C El l a papal a 9E B errgrrre on raiser cap urrrer rypereeieerr erru soak arr errgrrre err polyurellraneelerrrerrl unlessplugged ordarnaged then replace Fuel Fllu Elsmsnpreplam Fuel Filler E emenl repIace Fuel System Cap Tank Lines and Connsctions ins ect for l l i dl lj L integrity and correct il required l 3 f T an Fuel vaeer rrrrer rrrrer at charcoal cer ererere reee V 7 Heat Valve exhaust mamloldlfrnspect and Iubricate PCV Filler si cyllnderl clean Idle Speed lcurb and fasll and mixture check and reset il d l l d required PC HWS l lip E ren r e r m ne er eer and eee rr requrretr Coll and Spark Plug Nlresilnspecl and replace lt requlred PCV Flller l6 yllnd l Clean Spark Plugsf replace PCV Hoseswnspect and replace if required Ignrlron Trmrngwneek and sel rr requrreu PCV Ve Spark PIugs replace Drslrrbulor Advance Mechanlsmsicheck and correcl il required TAC syswm HDs mSp u and Ummm mqulred Dlslrrbulor Cap and Rol0r inspecl and replace ll required Transmission Controlled Spark Systsmsrmspect and correct il S a V r ir Hoses and rneeeer eee Choke Lrnkageiinspecl for lree mul errlenl correct rl required If required 9 Fuel 5ysIem Cap Tank Lines and Connecllnns lnspecl lor integrity and correct ll requrred Fuel Vapor Irllel Frller al Charcoal Canisler replace Air Guard Syslem H0ses rnspecl and correct rl required fluffy deposits may accumulate on the plugs during TAO systemernspectarru correct rr requrreu in t0wn driving when the engine is suddenly put un Vacuum Frtlrngs r roses and corrrleeirorrs inspect and der heavy load this material can melt and bridge the correct il required gap Scavenger Deposits B Fuol scavenger deposits shown may be white or yellow They may appear to be harmful but this is normal appearance with certain Icunmu SYSTEM brand fuels Such materials are designed to change the IllI l Plugs chemical nature of deposits to lessen misfire tendencies Notice that accumuliition on the ground Spark Umgs Shwld ht removed and examlned OY electrode and shell areas may be unusually heavy but hurnedlelectrodes and dirty fouled cracked or broken the material ls easlly removed Such plugs can be com l r la S Plugs Sl ld be replace at m l as M sidcred normal in condition and can be cleaned using vals recommended in the U S Emission Control Ser Standard practiclm vices Chart Rlugs with lower mileage may be cleaned chipped lnSulat Cl USu8lly results mm d me t Ste t r f r t0 he 4A 32 Alter berrdrrre me center electrode emrrrrg regepprrre ofthe cleanrnerthe center electrode should be flltd flat with plug Under certain conditions severe detonation can a lpoint file The gap must be set to 0 033 to 0 037 inch also split lnsulamr firing endsl me 33 P r D D c ri tr cesetve te 1 nl 10n amt 0 JBUSO y CX V temperatures produces melting of the center electrode an SOHIQW 3 B GI 9 POI Swl Flu l 1 rr r 1 r rn nd ereerreae trreuumre Refer to figure 4A 32 will appear relatively clean of deposits Check for cor Gap Bridging A May be traced to flying rect plug heat range overadvanced ignition timing and deposits in the combustion chamber In a few cases similar reasons foroverheating

Next

Next