Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

8123004

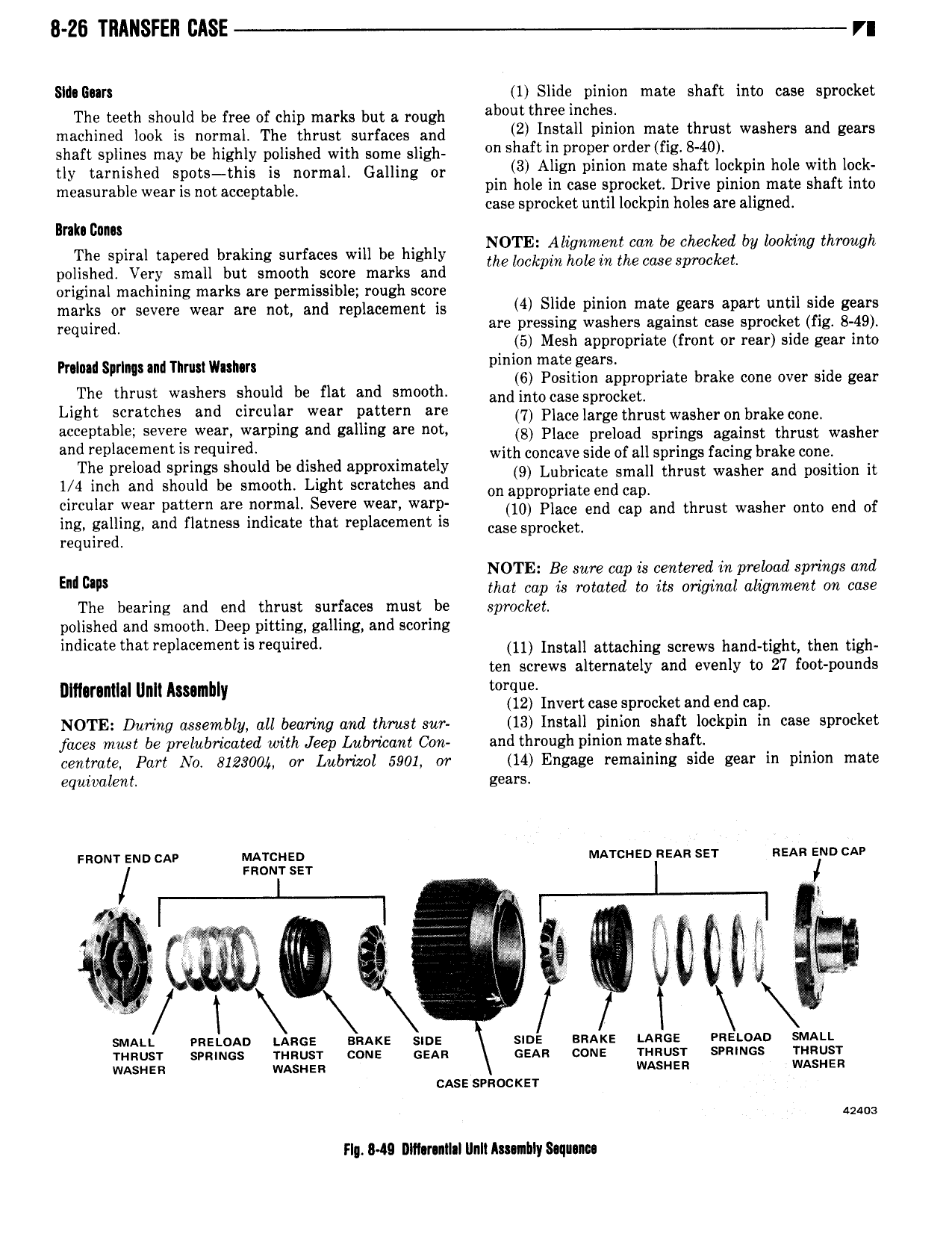

8 26 TRANSFER CASE r Silk Guan 1 Slide pinion mate shaft into case sprocket The teeth should be free of chip marks but a rough ab l h s machined look is normal The thrust surfaces and 2 Isstau pmwn mass thrust washers and gears shaft splines may be highly polished with some sligh shaft p F Y d f g 8 40 ny tarnished spots this is normal chang or 3 A mm hsft 2 s h 1 wh l5 l msasutallls Wear ls nat actaptabla pm hole in case sprocket Drive pinion mate shaft into case sprocket until lockpin holes are aligned llnlucnnax NOTE Alignment can be checked by looking through The spiral tapered braking surfaces will be highly A h ke polished Very small but smooth score marks and thelockmn Diem thgwsespmc t original machining marks are permissible rough score marks or severe wear are not and replacement is 4 Sllde D l0 mateagears apart until side gears are pressing was ers against case sproc e ig was 5 M l ll 2 es appropria e ron or rear sl e gear in Pnllml Sprlnp and Tbnlsl lllubm p mat sears 6 Position appropriate brake cone over side gear The thrust washers should be flat and smooth andlntoaass spmckatl Light scratches and circular wear pattern are 7 Platalargetl ustWashatanbtal sc0ns acceptable severe wear warping and galling are not Sl place ptaload springs agalnst thrust wssllsl and ls em ls qu d with concave side of all springs facing brake cone The praised S should be dishes s ly ol sublime small thrust washer and position it I 4 inch and should be smooth Light scratches and on appropriate and caps circular wear pattern are normal Severe wear warp 10 Place and cap and thrust washes Onto and of ing galling and flatness indicate that replacement is casa sprocket required NOTE Be sure cap is centered in preload springs and EM up that cap Ls rotated to its original alignment im case The bearing and end thrust surfaces must be sprocket polished and smooth Deep pitting galling and scoring lndlcam shatreplacementls l l d 11 Install attaching screws hand tight then tigh ten screws alternately and evenly to 27 foot pounds Dlllaranllal llnll Assembly I2 Invert case sprocket and end cap NOTE During assembly all bearing and thrust snr 13 Install pinion shaft lockpin in case sprocket fmces must be prelubricated with Jeep Lxulmbant Con and through pinion mate shaft centrote Part No 8123004 or Lnbrizol 5 901 or I4 Engage remaining side gear in pinion mate equivalent gears Fnom sun cnr Marcnen Marcuen ann sz r sean sun cnr rnour ser x l V l ly I ll l i x l g v LM U L ll atl t L J l swim eazcoan Lancs anx sm sms snake LARGE enacono smau runusr svnmcs runusr cone can can cons mnusr senmcs mnusr wasi use wasuzn wasuen wasuzn cass svnocxzr FI M9 llltlcrnllal llnll Auombly Seqnm

Next

Next