Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

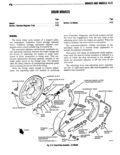

9 22 BRAKES MID WHEELS fl E v E m s t iirlf wheel cylinders require overhaul proceed to s ep l l3I IIIIlll 4 Disconnect brake line Do not bend line away ui Raise vehicle from wheel cylinder 4When cylinder is removed from Zi Remove wheels and drumu support plate line Awill separate from cylinder easily at Grasp adjusting lever with pliers and remove I5 Remove nyllnden mounting bvltn and nnmnve tang from hole in secondary shoe Cylmden 4 Place Brake Cylinder Clamps J 8002 over wheel 6 Remove lmks ind dug boots Push Ig ist P cylinders to hold pistons in place while shoes are plsmnsi and expanslcfn Spring fiom y r b removed Clean all metal parts with brake fluid 5 Remove return springs using Brake Spring 7 If bore is corroded or pitted replace wheel cyl Remover TeeiJ S057 inder lf bore is only stained or discolored it may be 6 Remove Secondary return Spring adjuster polished with crocus cloth Do not polish in a length cable primary return Spriugr cable guide adjuster wise direction polish by rotating cylinder around iever and adjuster Spriugu crocus cloth supported on fingers 7 Remove holddown springs and brakeshoes On rear brakes disengage parking brake cable from park CAUTION D0 mt hm e wheel Cylinders Uenmlnnn ing brake lever parking brake strut is removed with peffgrmedi elm cylinder ihomughly with brake brakeshoe assemblies fluid ly 8 Inspect pistons If scored or worn replace If clunlnu and lnslmmnn discolored or stained pistons may be lightly polished Ulllnlnq with crocus cloth Clean pistons thoroughly if they were polished n L L 5535 2 i 3J 2ii i2iV 21 i i3 9 on Crim bm in me inn nun no drums with a Snap and Water Solution not lubricete pistons or cups Assemble wheel cylinder For brake fluid contamination clean all parts with components iimrthigl D0 not attempt to clean contaminated brake CAUTION Piston Cups Should have fmt ends facing open ends of cylinder and flared ends of cups facing imiimitii interior oj cylinder Pull bank wheel cylinder duet boot in n or io clean wheel cylinder mounting surface on sup leakage If evidence of leakage is observed the cylm uert plate Clean brukeiiue fitting and threadu der should be disassembled and inspected as described ui Start brake line fitting iu wheel cylindeiu In Wheelcylmden Attach wheel cylinder to support plate and tighten Pnmn laden nf me hmm mvvnn nlm Wnn nne brake line fitting rigiiten cylinder mounting mite to sandpaper or emery cloth If grooves which may 18 i uet u0uud5 turuue restrict shoe movement still exist after polishing the brake support plate must be replaced Attempting to remove grooves by grinding may result in improper Snllm Hm shoe to drum contact 1 Remove dirt using compressed air or cloth Pol Inspect the lining wear pattern If the wear across ish anchor pin with crocus cloth the width of the lining is uneven check drums for 2 Polish ledges of brake support plate with fine bell mouthed condition inspect drums for correct posi sandpaper or emery cloth If grooves which may tion and inspect support plate for distortion Inspect restrict shoe movement still exist after polishing re all springs for evidence of overheating discoloration place support plate and fractures The self adjusting cable should be in spected for kinks fraying and an elongated eyelet CAUTION Attempting to Tmove moves by mimi Inspect the adjusting screw for freedom of rotation mg may result in imimmey 8 we g0 dmm umgiw D0 and the self adjuster lever for wear and distortion my agggmpg to reduce migeg or grooves by grinding mm mllmn 3 Inspect support plate for warpage or cracks 1 Inspect for evidence of leakage Pull back dust 4 Check torque of support plate to axle flange boot and inspect condition of rubber piston cups and bolts cylinder bore 5 Check anchor pin for wear or loose attaching 2 Inspect bleeder screw and hydraulic line con part nection for evidence of leakage Check brake lines for 6 Replace support plate if inspection reveals non swelling distortion kinks and cracks repairable defect

Next

Next