Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

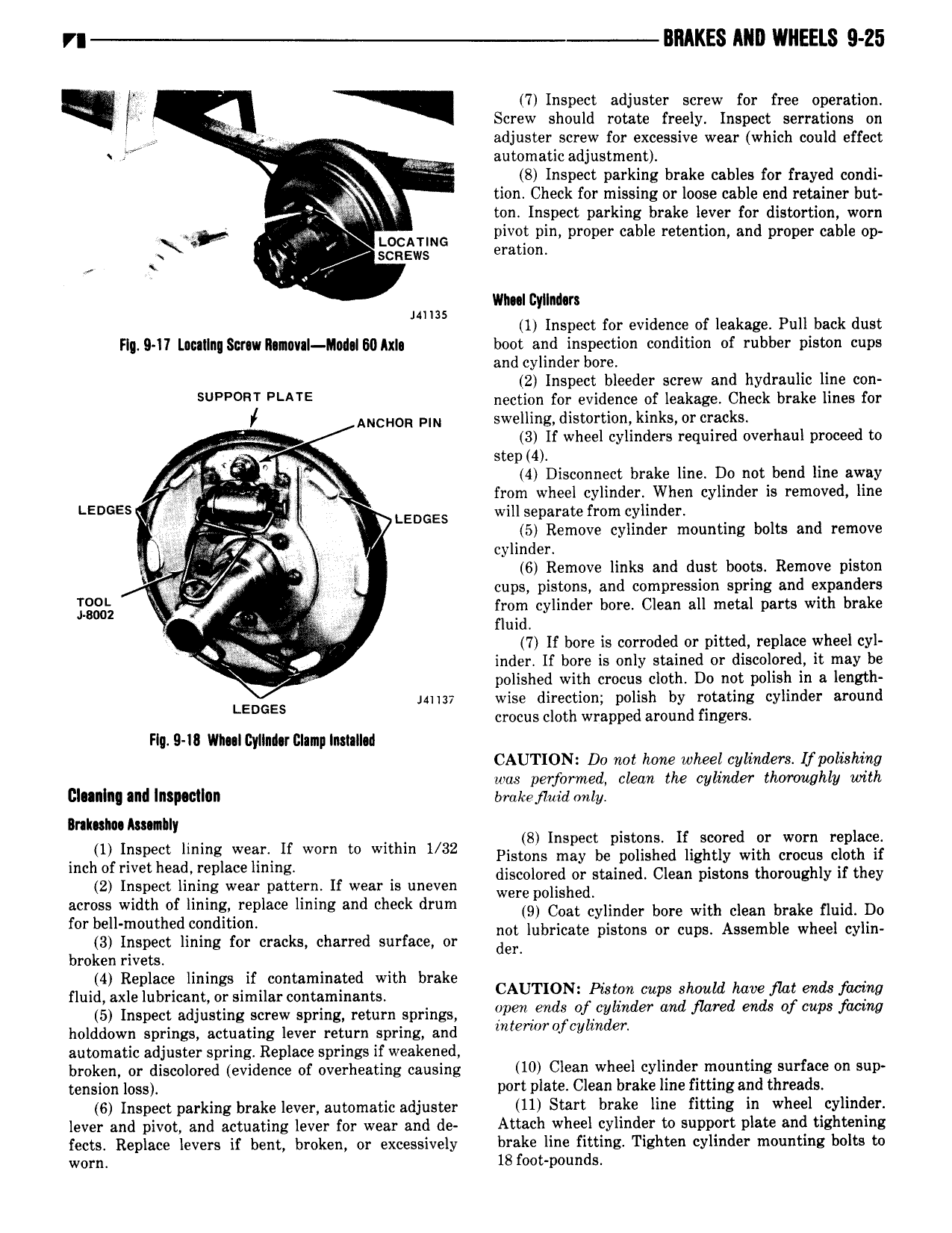

VI BRAKES MII WHEELS 9 25 i i 7 Inspect adjuster screw for free operation Screw should rotate freely Inspect serrations on 4 adjuster screw for excessive wear which could effect l f automatic adjustment t 8 Inspect parking brake cables for frayed condi X tion Check for missing or loose cable end retainer but fn t ton Inspect parking brake lever for distortion worn pivot pin proper cable retention and proper cable op Locnnue mmm K scnsws M Us Vllml tyllmkrs 1 Inspect for evidence of leakage Pull back dust Fly 9 17 Lltllllll SNOW IIIIWII IIOd 60IxI boot and inspection condition of rubber piston cups and cylinder bore 2 Inspect bleeder screw and hydraulic line con uP I Fl ATE nection for evidence of leakage Check brake lines for ANCHOR PIN swelling distortion kinks or cracks 3 If wheel cylinders required overhaul proceed to e step 4 Z 0 n 4 Disconnect brake line Do not bend line away r Y from wheel cylinder When cylinder is removed line EDGES if E l LEDGES will separate from cylinder 7 5 Remove cylinder mounting bolts and remove cylinder r 6 Remove links and dust boots Remove piston V cups pistons and compression spring and expanders I S30 7 I from cylinder bore Clean all metal parts with brake l fiuid l 7 If bore is corroded or pitted replace wheel cyl inder If bore is only stained or discolored it may be R V polished with crocus cloth Do not polish in a length LEDGES mis wise direction polish by rotating cylinder around crocus cloth wrapped around fingers Hq 9 10 Vlh l Cyllnlar Clamp InmlI d CAUTION Do not hone wheel cylinders U polishing was performed clean the cylinder thoroughly with Glnnlng and Inspwtlnn bmkejzuad only Ilr k M Amnlly 1 i c img we if wm wm Me 5 i J i Z d 2i 5352 2TE inch Of rivet head replacellning discolored or stained Clean t th hl f h pls ons oroug y 1 t ey 2 Inspect lining wear pattern If wear is uneven were polished cr SilW dthh iQillnl replace hmng and check drum 9 Coat cylinder bore with clean brake fluid Do Dr e In wut E Fqn mon not lubricate pistons or cups Assemble wheel cylin 3 Inspect lining for cracks charred surface or der broken rivets 4 Replace linings if contaminated with brake fluid axle lubricant or similar contaminants CAUTION Plmjn cups Shwld have fm ends fuiwg 5 Inspect adjusting screw spring return springs VFW gms f l l der and flared M8 f wps fmw holddown springs actuating lever return spring and li T Ofcyhndeli automatic adjuster spring Replace springs if weakened broken or discolored evidence of overheating causing 10 Clean wheel cylinder mounting surface on sup tgngiqn logs port plate Clean brake line fitting and threads 6 Inspect parking brake lever automatic adjuster 11 Start brake line fitting in wheel cylinder lever and pivot and actuating lever for wear and de Attach wheel cylinder to support plate and tightening fects Replace levers if bent broken or excessively brake line fitting Tighten cylinder mounting bolts to worn 18 foot pounds

Next

Next