Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

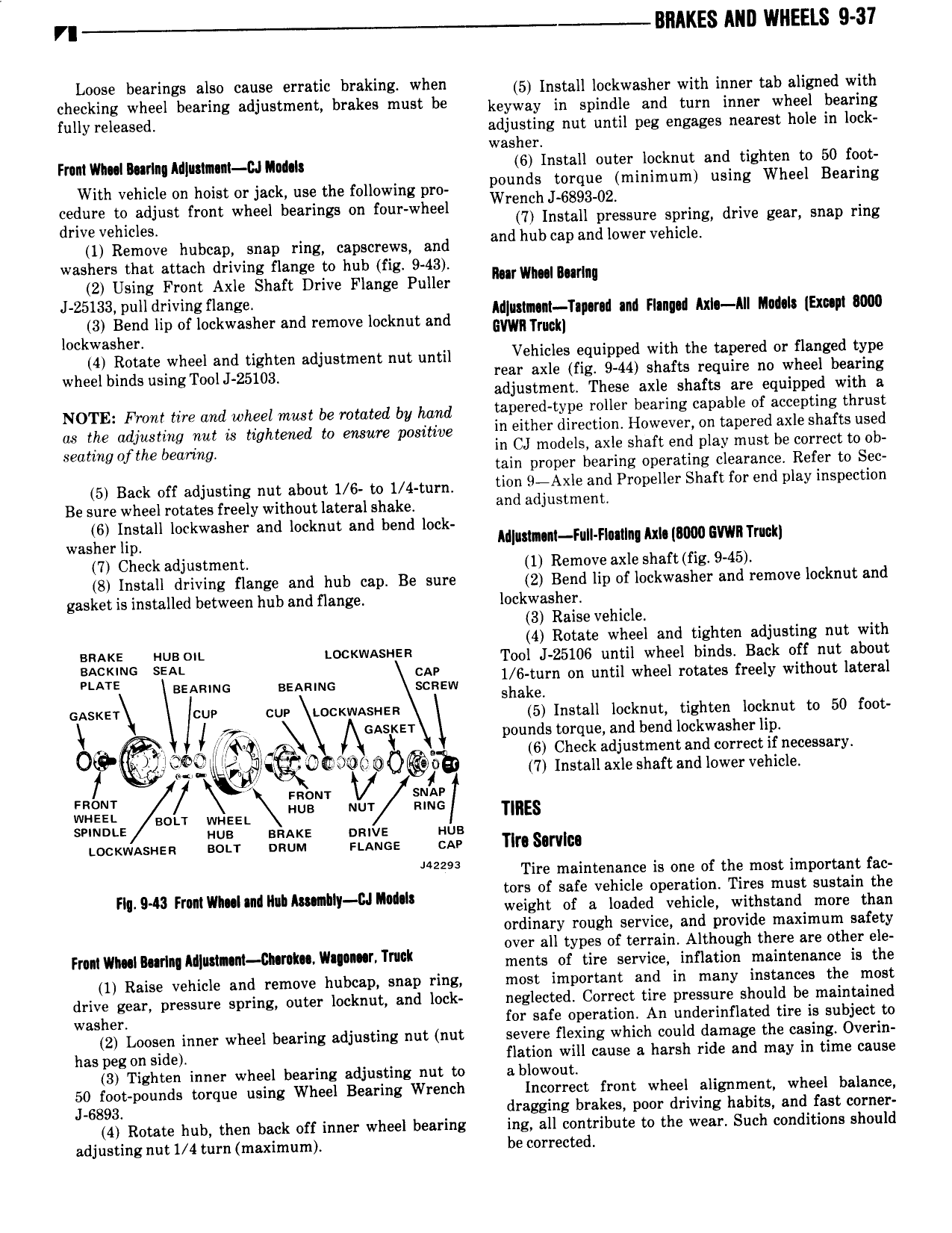

r BRAKES MII WHEELS 9 37 L 9 bearings elev wee erratic brakina when 5 ineteu ieekwaeher with inner tab aligned with checking Wheel bearing adnustment brakes must be keyway in epinaie and tum inner wheel bearing fully l d adjusting nut until peg engages nearest hole in lock washer Fnn wh ggy Ad gg1 cJ q g 6 Install outerrlocknut and tiglwn ti gl foot With vehicle on hoist or jack use the following pro ul 1d ggg 2 mln mum usmg hee eating cedure to adjust front wheel bearings on four wheel W7 Install pressure spring drive gear snap ring drive vehicles ii Remove ieeeee snap see capscrews eee mhubcavand W V h e washers that attach driving flange to hub fig 9 43 2 Using Front Axle Shaft Drive Flange Puller Mlrwmlauml J 25133 pulldriving ilange M t d d H M A M Ex wm 3 Bend lip of lockwasher and remove locknut and Gmqcwkl lnn In ml R I In lockwasher 4 Rotate wheel and tighten adjustment nut until Vehlcles Wulpped wlth the mPe d or flanged tlfpe Wheelbinds using j 0 l 25103 rcgar axle f1gi h9 44 shafts rfguire no wheeji beatxzng a jus men ese axe s a are equippe wi a Nom Front tire eee wheel me be rotated by hand tapered tyre reuer heme b Ofdeccfvtjye hr ues the adjusting nut La tightened to mum positive in either direction However on tapere axes a ts use seating ofthe bearing ln CJ models axle shaft end play must be correct to ob tain proper bearing operating clearance Refer to Sec 5 Back Off adjusting nut about 1 6 to 1 4 Lm n tion 9jAxle and Propeller Shaft for end play inspection Be sure wheel rotates freely without lateral shake and dI tm t 6 Ita111k li dlkt db alk 9 was er an nu nuiumun ruin rm ui m0 awnrmn 7 Cheek adjustment 1 Remove axle shaft fig 9 45 B Install driving flange and hub cap Be sure 2 Bend lip of lockwasher and remove locknut and gasket is installed between hub and flange lockwasher 3 Raise vehicle 4 Rotate wheel and tighten adjusting nut with 2 FNG L K As ER Tool J 25l06 until wheel binds Back off nut about PLATE BEARWG BEARING ggssw Ligtgirn on until wheel rotates freely without lateral GA KET cu CUP OCKVVASHER 5 Install locknut tighten locknut to 50 foot ry J AGASKET pounds torque and bend lockwasher lip O i V ewh ji ll 6 Check adjustment and correct if necessary Y lZ 0 7 Install axle shaftand lower vehicle FRONT Faour SNAP waeei EOL EEL UB TIRES E nun anne omve Hue Loc wAsnen sou onum nance car TIN Sarvlca zzga Tire maintenance is one of the most important fac tors of safe vehicle operation Tires must sustain the I 943 Frmwhu ml H M u num weight of a loaded vehicle withstand more than ordinary rough service and provide maximum safety over all types of terrain Although there are other ele F IB l I c w r 1 k ments of tire service inflation maintenance is the 1 Raise vehicle and remove hubcap snap ring most important and in many instances the most drive gear pressure spring outer locknut and lock neglected Correct tire pressure should be maintained washer for safe operation An underinflated tire is subject to 2 Looseln inner wheel bearing adjusting nut nut sfvkere flexing whichhcouhi dgmagg the casing Overin haspegon si e a ion wi cause a ars ri e an may in ime cause 3 Tighten inner wheel bearing adjusting nut to ablowout 50 foot pounds torque using Wheel Bearing Wrench Incorrect front wheel alignment wheel balance J 6893 dragging brakes poor driving habits and fast corner 4 Rotate hub then back off inner wheel bearing ing all contribute to the wear Such conditions should adjusting nut 1 4 turn maximum be corrected

Next

Next