Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

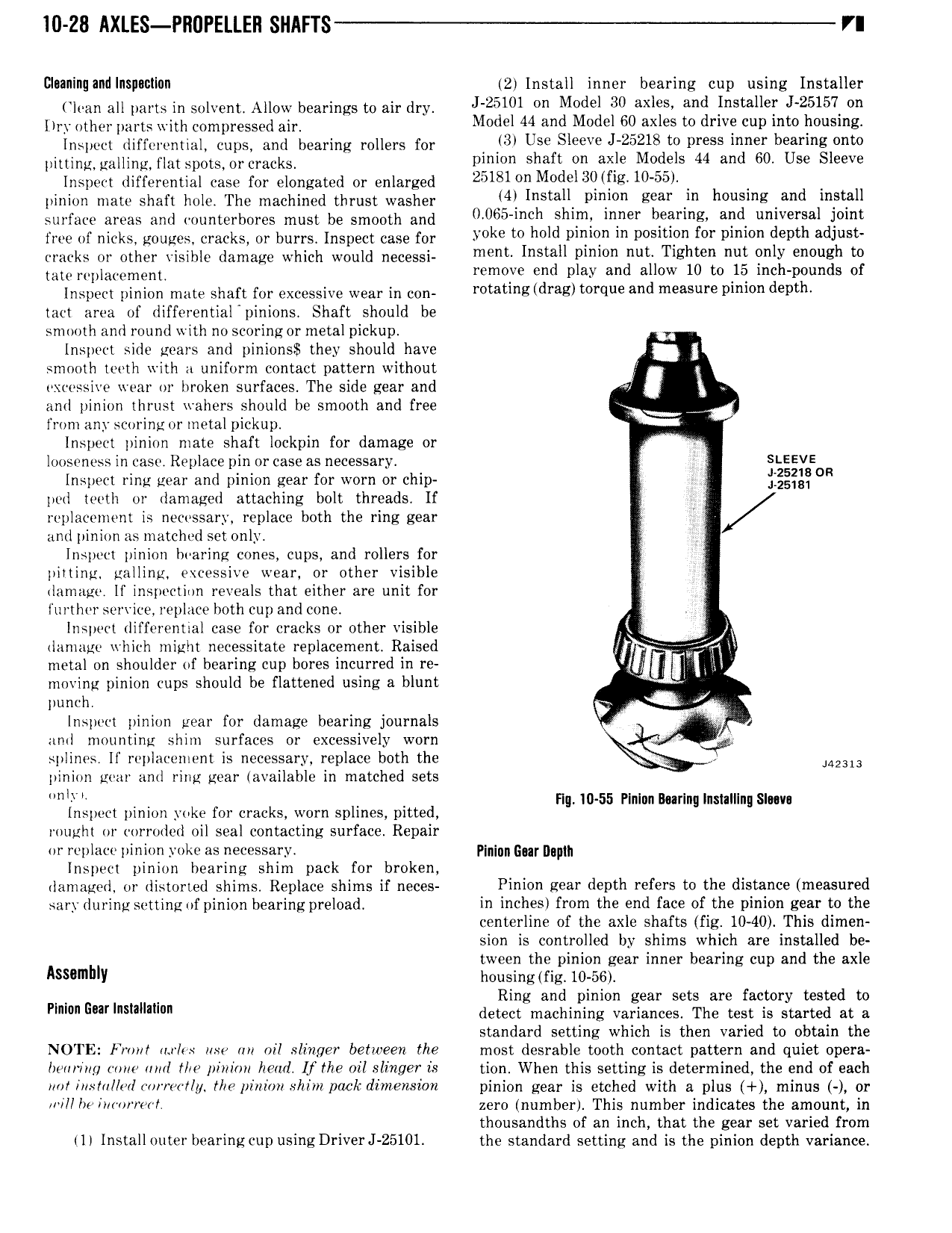

l0 28 AXLES PRUPELLEH SHIlFTS VI 8tllII and Inspntllun 2 Install inner bearing cup using Installer f lt an all llalls in St lt alt Allow bearings to air ary J 25101 MMM 30 Miss and lmtellsr 25157 Dm Mm Dana with Compressed ain Model 44 and Model 60 axles to drive cup into housing lnspcct dil fcl entlal cups and bearing rollers for algl USE Sleeve 20218 tu Press luuer beimug umu pimnavgamnayflmapotaym Cracka pinion shaft on axle Modvels 44 and 60 Use Sleeve Inspect differential case for elongated or enlarged 25181 M d l3ullTlg 10 5Dl pinion mate shaft hole The machined thrust washer I s au pluwn gear m hwsmg End mfball surface areas and collnterbores must be smooth and O 0 5 h Shu m r u g aud unwersal l mt free of nicks gougcs cracks or burrs Inspect case for luke to h lu pullun m p SmP for pmmu depth ad lust cracks or other visible damage which would naceasp ment Install pinion nut Tighten nut only enough to wm H Dla ma L remove end play and allow 10 to lla lnch pounds of inspect pinion mate shaft for excessive wear in con rututlng drag torque anu measure puuou uepthi tact area of clifferential pinions Shaft should be smooth and round with no scoring or metal pickup Y Inspect side gears and pinionsiii they should have I smooth teeth with ll uniform contact pattern without g excessive wear or broken surfaces The side gear and and pinion thrust wahers should be smooth and free A from any scoring or metal pickup 4 Inspect pinion mate shaft lockpin for damage or Iooseness in case Replace pin or case as necessary F SLEEVE Inspect ring gear and pinion gear for worn or chip g OR pt l teeth or damaged attaching bolt threads If l epla emt nt is necessary replace both the ring gear and pinion as matched sct only I Inspect pinioll hearing cones cups and rollers for pitting galling excessive wear or other visible V llumllge lf inspection reveals that either are unit for l lll tllcl service replace both cup and cone E Inspect tlifferelltlal case for cracks or other visible X i llanltlgc which might necessitate replacement Raised I ryyxv metal on shoulder of bearing cup bores incurred in re N moving pinion cups should be flattened using a blunt V punch Inspect pinion gear for damage bearing journals 4 uml mounting shim surfaces or excessively worn splines Il replacement is necessary replace both the 4 Mas pinioll gear and ring gear available in matched sets i 1 Fig I0 55 Plnlnn Burlng Installing Slam Inspect pinion yoke for cracks worn splines pitted rollght or corroded oil seal contacting surface Repair or replace pillion yoke as necessary Pininn Eur Dnpttl Inspect pinion hearing shim pack for broken llanlaged or distorted shims Replace shims if neces Pinion gear depth refers to the distance measured sary durillg scttlngof pinion bearing preload in inches from the end face of the pinion gear to the centerline of the axle shafts fig 10 40 This dimen sion is controlled by shims which are installed be tween the pinion gear inner bearing cup and the axle Assamhll housing fig 10 56 Ring and pinion gear sets are factory tested to Plum u l lall l detect machining variances The test is started at a standard setting which is then varied to obtain the NOTE 1 ronr ll l lls use lol oil slinger between the most desrable tooth contact pattern and quiet opera llevlmlg cone und the pmiml lleud If the oil slinger is tion When this setting is determined the end of each unl lmlrlllwl wowretilly thepz nz oll shim pack dimension pinion gear is etched with a plus minus or will he illl o rccl zero number This number indicates the amount in thousandths of an inch that the gear set varied from li Installouter bearing cup using Driver J 25101 the standard setting and is the pinion depth variance

Next

Next