Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

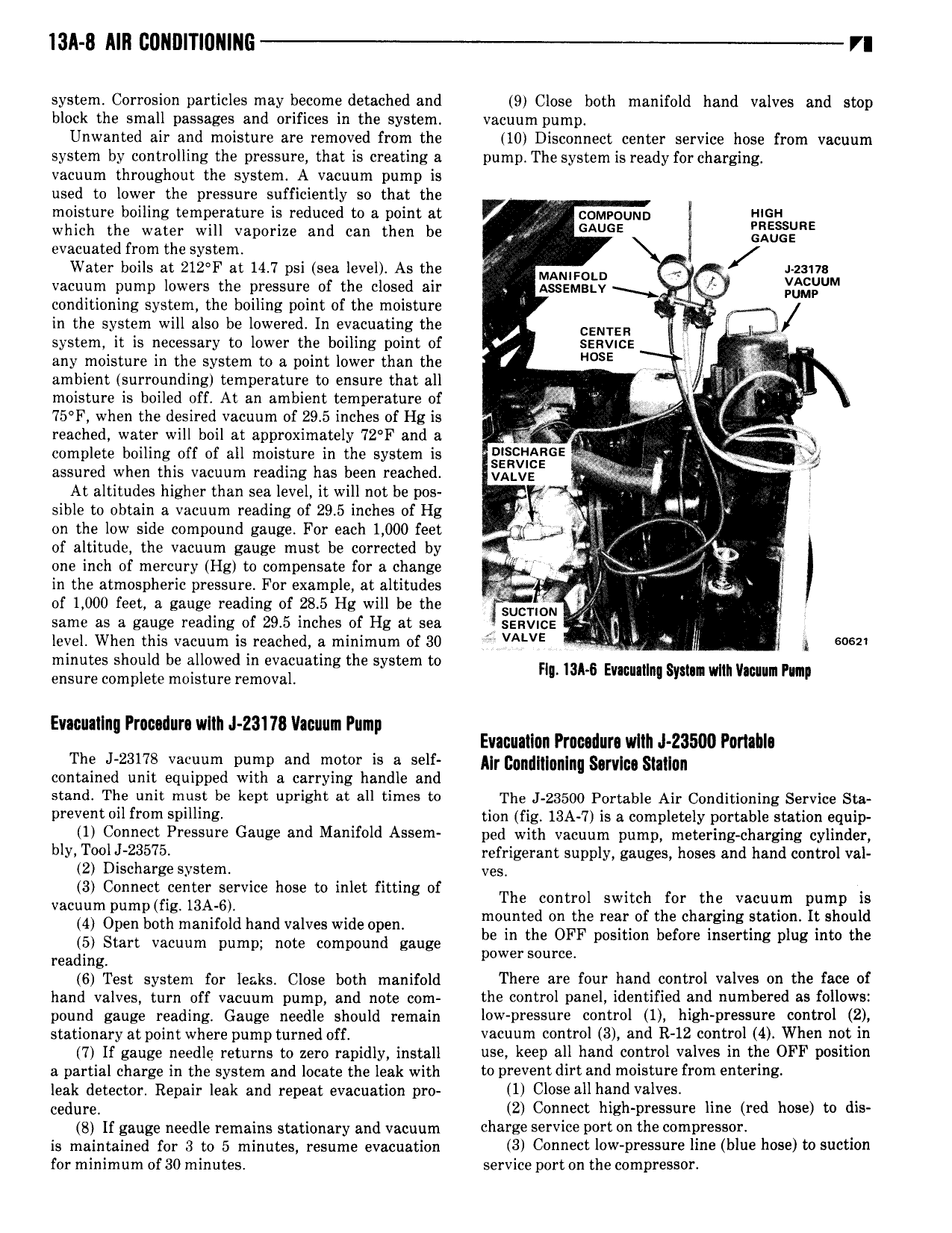

13A 8 MH GDNDITIGNING VI system Corrosion particles may become detached and 9 Close both manifold hand valves and stop block the small passages and orifices in the system vacuum pump Unwanted air and moisture are removed from the 10 Disconnect center service hose from vacuum system by controlling the pressure that is creating a pump The system is ready for charging vacuum throughout the system A vacuum pump is used to lower the pressure sufficiently so that the moisture boiling temperature is reduced to a point at r i comvounn l HIGH which the water will vaporize and can then be GAUGE zi ggRE evacuated from the system Water boils at 212 F at 14 7 psi sea level As the 4 2 1711 vacuum pump lowers the pressure of the closed air e lgt gil3 21 KQSBUM conditioning system the boiling point of the moisture g in the system will also be lowered In evacuating the CENTER n system it is necessary to lower the boiling point of 0 SERVICE i any moisture in the system to a point lower than the E I ambient surrounding temperature to ensure that all p g i moisture is boiled off At an ambient temperature of 3 ii 75 F when the desired vacuum of 29 5 inches of Hg is n l n reached water will boil at approximately 72 F and a IK V V complete boiling off of all moisture in the system is g iQ GE 7 j tx QQ assured when this vacuum reading has been reached VALVE Q m l t T At altitudes higher than sea level it will not be pos it I V sible to obtain a vacuum reading of 29 5 inches of Hg Wi 3 4 on the low side compound gauge For each 1 000 feet ZX n of altitude the vacuum gauge must be corrected by V QI r one inch of mercury Hg to compensate for a change A W l g gf y in the atmospheric pressure For example at altitudes it Mig Q of 1 000 feet a gauge reading of 28 5 Hg will be the SUCTION ci same as a gauge reading of 29 5 inches of Hg at sea sznvics P level When this vacuum is reached a minimum of 30 i VALVE i l f fl 1 6062 minutes should be allowed in evacuating the system to ensure complete moisture removal H luis Emulllnl sym wml V um Pm Evacuatloo Procedure wltli J 23178 Vacuum Pump Evacuation Procedure wltlt J 23500 Portable The J 23178 vacuum pump and motor is a self Mr gomnnonlnq gan Smhn contained unit equipped with a carrying handle and stand The unit must be kept upright at all times to The J zasoo Portable Air Conditioning serviee sto Pi V i Oil fmm SDilli E tion fig 13A 7 is a completely portable station equip 1 Connect Pressure Gauge and Manifold Assem pod with vacuum pump metering charging cylinder bly Tool J 2 575 refrigerant supply gauges hoses and hand control val 2 Disc arge system ves V8cs iinC f nl g TnVme hose to mm mmm Of The control switch for the vacuum pump is in Open pon nieniroia hand valves wise open gevnfg g cept g gg ggt qg ignjjegglj 5 Start vacuum pump note compound gauge pgvxr scarce WSI mn e O g p g readin 6 gTest system for leaks Close both manifold There are four hand control valves on the face of hand valves turn off vacuum pump and note com the control panel identified and numbered as follows pound gauge reading Gauge needle should remain low pressure oofigol filkfiggh p eis 1 e z 1ntrol 2 stationar at pointwhere pump turned off vacuum contro an con ro en no in 7 Ifygauge needle returns to zero rapidly install use keep all hand control valves in the OFF position a partial charge in the system and locate the leak with to prevent dirt and moisture from entering leak detector Repair leak and repeat evacuation pro 1 Close all hand valves cedure 2 Connect high pressure line red hose to dis S If gauge needle remains stationary and vacuum charge service port on the compressor is maintained for 3 to 5 minutes resume evacuation 3 Connect low pressure line blue hose to suction for minimum of 30 minutes service port on the compressor

Next

Next