Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

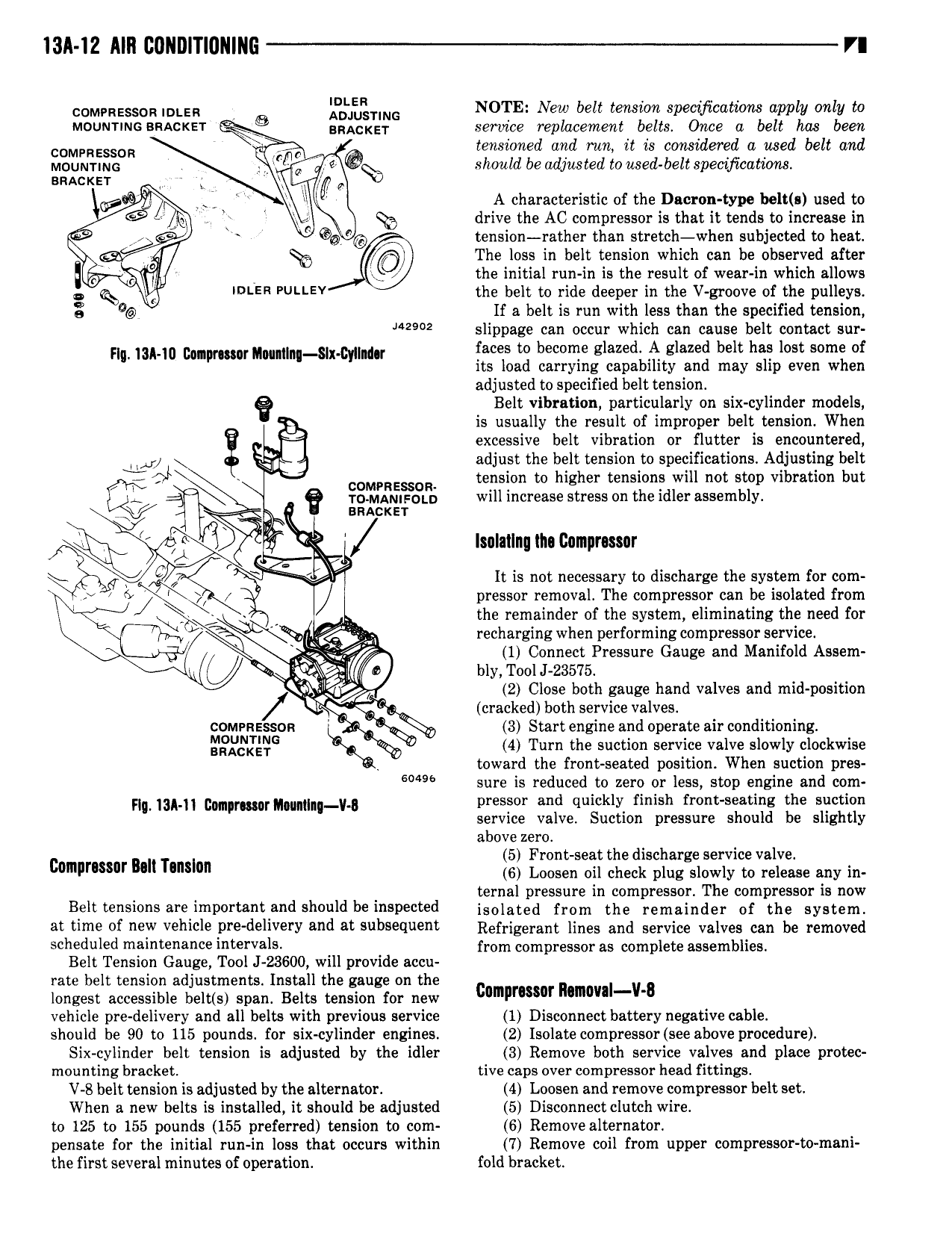

13A 12 MII COIIII TIOII IIli VI COMPRESSOR IOLER TILEQTING NOTE New belt tension specljications apply only to Moummo BRACKET BRACKET service replacement belts Once a belt has been V iensioned and mn it is considered a used belt and m z R e should be adjusted to used belt speci icativrls seackzr h 4 V W P i V characteristic of the Dacron type belt s used 9 drive the AC compressor is that it tends to increase in g tension rather than stretcI1 when subjected to heat av 4 The loss in belt tension which can be observed after G the initial run in is the result of wear in which allows O Q IDLER PULLEV the belt to ride deeper in the V groove of the pulleys S If a belt is run with less than the specified tension 2 2 slippage can occur which can cause belt contact sur H 13A w no M ln s IM faces to become glazed glazed belt has lost some of u Iwmnr W nl Hm u its load carrying capability and may slip even when adjusted to specified belt tension 9 Belt vibration particularly on six cylinder models ra is usually the result of improper belt tension When excessive belt vibration or flutter is encountered My adjust the belt tension to specifications Adjusting belt Z ol tension to higher tensions will not stop vibration but e v COMPRESSOR 9 g p q p will increase stress on the idler assembly il i E it 8 I I IIII III Cnmprggsnr gw O l It is not necessary to discharge the system for com er VM pressor removal The compressor can be isolated from g r the remainder of the system eliminating the need for O recharging when performing compressor service 1 Connect Pressure Gauge and Manifold Assem U bly Tool J 23575 YW 2 Close both gauge hand valves and mid position h cracked both service valves comwnssson t 3 Start engine and operate air conditioning Q j gll G R 4 Turn the suction service valve slowly clockwise toward the front seated position When suction pres sure is reduced to zero or less stop engine and com H r 3 H cm nm MOM y pressor and quickly finish front seating the suction U II I service valve Suction pressure should be slightly above zero 5 Front seat the discharge service valve mmllnssar mn Tmsllm 6 Loosen oil check plug slowly to release any in ternal pressure in compressor The compressor is now Belt tensions areimportantland should be inspected isolated I Om the remainder Of the System at tune of new vslncle prssislwsny end st snbsequsnr Refrigerant lines and service valves can be removed sshsdulsd malmgnance lP 3al5 U d from compressor as complete assemblies Belt Tension auge oo 23600 wi provi e accu rate belt tension adjustments Install the gauge on the longest accessible belt s span Belts tension for new camllnssar m I v 8 vehicle pre delivery and all belts with previous service 1 Disconnect battery negative cable should be 90 to 115 pounds for six cylinder engines 2 Isolate compressor see above procedure Six cylinder belt tension is adjusted by the idler 3 Remove both servlice dv alves and place protec mounting bracket tive caps over compressor ea ittings V S belt tension is adjusted by the alternator 4 Loosen and remove compressor belt set When a new belts is installed it should be adjusted 5 Disconnect clutch wire to 125 to 155 pounds 155 preferred tension to com 6 Remove alternator 4 pensate for the initial run in loss that occurs within 7 Remove coil from upper compress0r to mam the first several minutes of operation fold bracket

Next

Next