Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

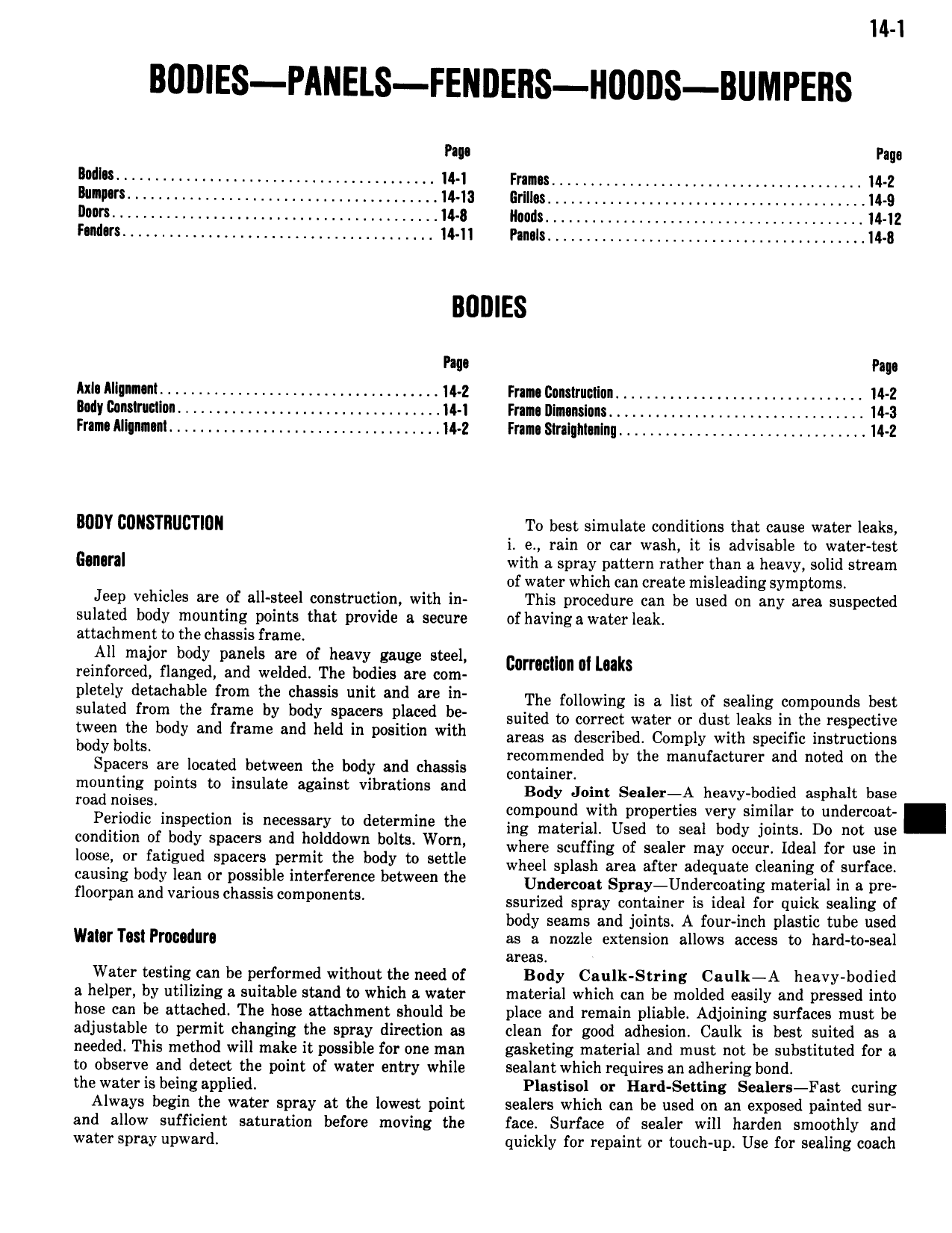

14 1 BOD ES PANELS FENDEIiS HOOI S BUMPE 1S Pom Pago Ilodlo 4 4 14 1 Fran 14 2 lunar il 13 Grlllos 4 4 II 9 Door 14 I Iiood 4 II 12 Fondors 4 14 11 Ponols 4 4 4 IM Pogo Pogo Axlo Allgrmonl 14 2 Fran Construction 4 4 14 2 lowly Cormrooilon 14 1 Fran lllmmlooa r 14 3 From Aliqnnoi 14 2 Fron Stralohlonlnu r r 14 2 BOIIY CONSTRUCTION To best simulate conditions that cause water leaks i e rain or car wash it is advisable to water test GQIIQRI with a spray pattern rather than a heavy solid stream of water which can create misleading symptoms Jeep vehicles are of all steel construction with in This procedure can be used on any area suspected sulated body mounting points that provide a secure of havingawater leak attachment to the chassis frame All major body panels are of heavy gauge steel reinforced flanged and welded The bodies are com cnrmmnn M Luk plitely demhablt from the chassis unit and are in The following is a list of sealing compounds best su me fmm h frame by my e 12iz be suited to correct wsees or dust leaks in the respective tween the b dy and frame and held m p sm n with areas as described Comply with specific instructions lmdy b lts recommended by the manufacturer and noted on the Spacers are located between the body and chassis container mounting points to insulate against vibrations and Body joint 5 4 hsavy m 1ied asphalt base mad HPISTS compound with properties very similar to undercoat Periodic inspection is necessary to determine the ing meterieI Used to seal body juime D0 not use y i Of My a Md 2 w Wm where sesmsg of sealer may occur Ideal for use in s r fatigued spacer pgrmlt the b dy to settle wheel splash area after adequate cleaning of surface causing body lean or possible interference between the Undercoat sp y Underc0ating materiel in e me n rpa and Varmus chassis mp tS ssurized spray container is ideal for quick sealing of body seams and joints A four inch plastic tube used Walqr T3 Pr 3 l rq as a nozzle extension allows access to hard to seal areas Water testing can be performed without the need of Body Caulk String Caulk A heavy bodied a helper by utilizing a suitable stand to which a water material which can be molded easily and pressed into hose can be attached The hose attachment should be place and remain pliable Adjoining surfaces must be adjustable to permit changing the spray direction as clean for good adhesion Caulk is best suited as a needed This method will make it possible for one man gasketing material and must not be substituted for a to observe and detect the point of water entry while sealant which requires an adhering bond the water is beingapplied Plastisol or Hard Setting SeaIers Fast curing Always begin the water spray at the lowest point sealers which can be used on an exposed painted sur and allow sufficient saturation before moving the face Surface of sealer will harden smoothly and water spray upward quickly for repaint or touch up Use for sealing coach

Next

Next