Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

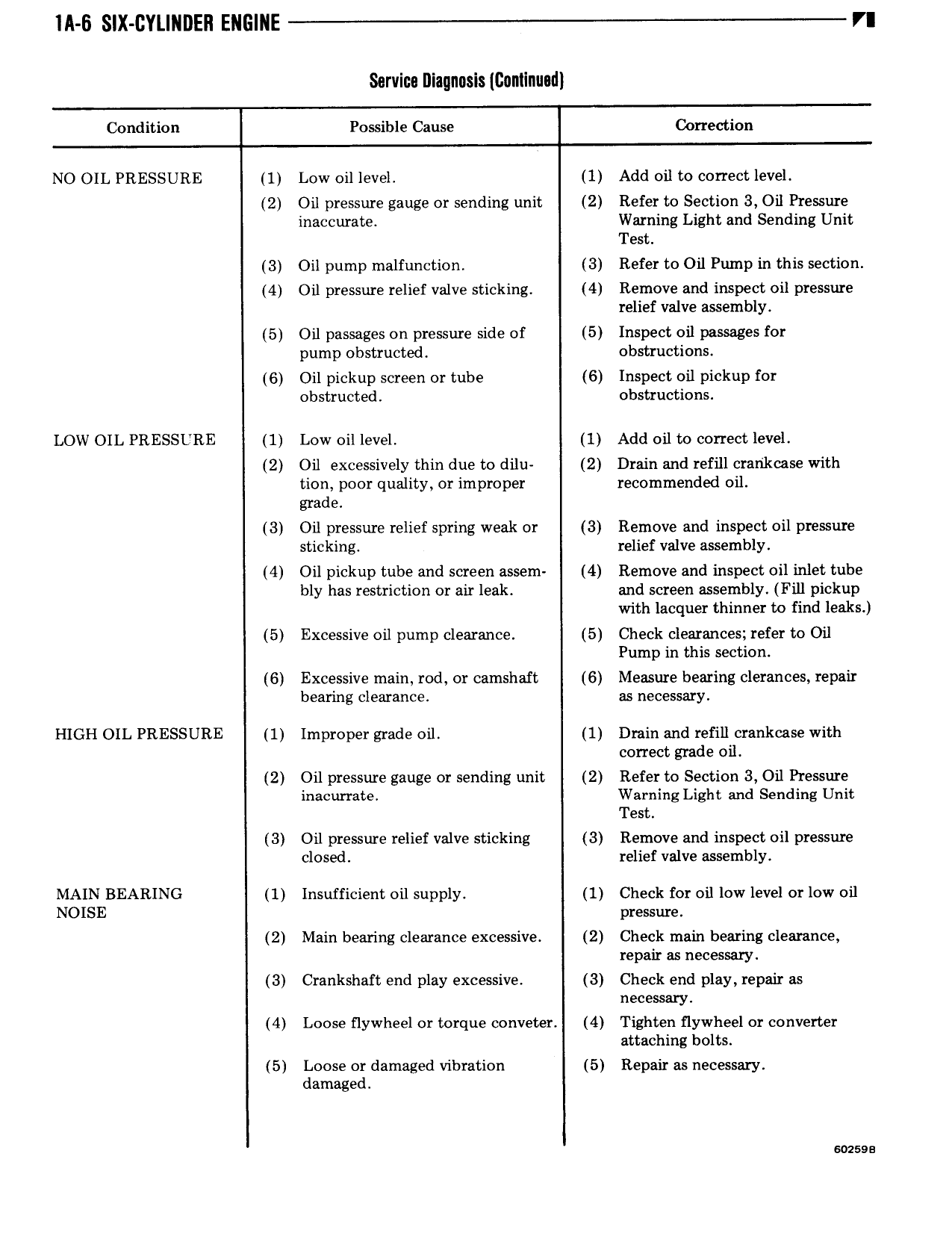

IA 6 SIX CYLINDER ENGINE VI Service Diagnosis Ganlinuul Condition Possible Cause Correction NO OIL PRESSURE 1 Low oil level 1 Add oi l to correct level 2 Oil pressure gauge or sending unit 2 Refer to Section 3 Oil Pressure inaccurate Warning Light and Sending Unit Test 3 Oil pump malfunction 3 Refer to Oil Pump in this section 4 Oil pressure relief valve sticking 4 Remove and inspect oil pressure relief valve assembly 5 Oil passages on pressure side of 5 Inspect oil passages for pump obstructed obstructions 6 Oil pickup screen or tube 6 Inspect oi l pickup for obstructed obstructions LOW OIL PRESSURE 1 Low oil level 1 Add oil to correct level 2 Oil excessively thin due to dilu 2 Drain and refill crarikcase with tion poor quality or improper recommended oil grade 3 Oil pressure relief spring weak or 3 Remove and inspect oil pressure sticking relief valve assembly 4 Oil pickup tube and screen assem 4 Remove and inspect oil inlet tube bly has restriction or air leak and screen assembly Fill pickup with lacquer thinner to find leaks 5 Excessive oil pump clearance 5 Check clearances refer to Oil Pump in this section 6 Excessive main rod or camshaft 6 Measure bearing clerances repair bearing clearance as necessary HIGH OIL PRESSURE 1 Improper grade oil 1 Drain and refill crankcase with correct grade oil 2 Oil pressure gauge or sending unit 2 Refer to Section 3 Oil Pressure inacui rate Warning Light and Sending Unit Test 3 Oil pressure relief valve sticking 3 Remove and inspect oil pressure closed relief valve assembly MAIN BEARING 1 Insufficient oil supply 1 Check for oil low level or low oil NOISE pressure 2 Main bearing clearance excessive 2 Check main bearing clearance repair as necessary 3 Crankshaft end play excessive 3 Check end play repair as necessary 4 Loose flywheel or torque conveter 4 Tighten flywheel or converter attaching bolts 5 Loose or damaged vibration 5 Repair as necessary damaged sozsea

Next

Next