Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

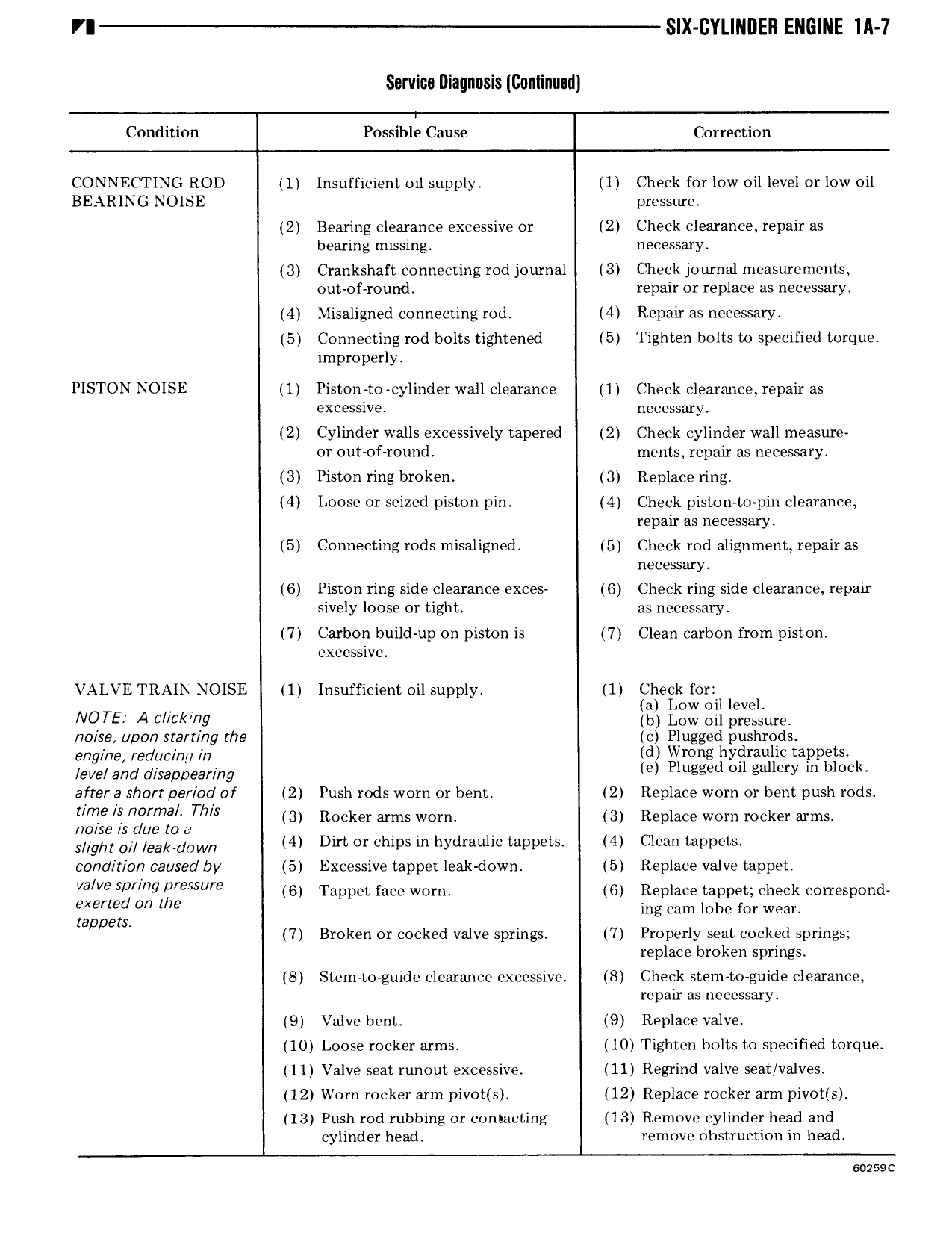

VI SIX CYLINDEN ENGINE lA 7 Sorvicu Diagnosis Dnniinnad Condition Possible Cause Correction CONNECTING ROD 1 Insufficient oil supply 1 Check for low oil level or low oil BEARING NOISE pressure 2 Bearing clearance excessive or 2 Check clearance repair as bearing missing necessary 3 Crankshaft connecting rod journal 3 Check journal measurements out of round repair or replace as necessary 4 Misaligned connecting rod 4 Repair as necessary 5 Connecting rod bolts tightened 5 Tighten bolts to specified torque improperly PISTON NOISE 1 Piston to cylinder wall clearance 1 Check clearance repair as excessive necessary 2 Cylinder walls excessively tapered 2 Check cylinder wall measure or out of round ments repair as necessary 3 Piston ring broken 3 Replace ring 4 Loose or seized piston pin 4 Check piston to pin clearance repair as necessary 5 Connecting rods misaligned 5 Check rod alignment repair as necessary 6 Piston ring side clearance exces 6 Check ring side clearance repair sively loose or tight as necessary 7 Carbon build up on piston is 7 Clean carbon from piston excessive VALVE TRAIl NOISE 1 Insufficient oil supply 1 Cheik for a ow oil level OTE A clicking b Low oil pressure noise upon starring the c Plugged pushrods Engine reducing jr d Wrong hydraulic tappets level and disappearing e Plugged oil gallery in block afrer a short period of 2 Push rods worn or bent 2 Replace worn or bent push rods tmjg wma Th 3 Rocker arms worn 3 Replace worn rocker arms noise is due to a S ight 0 63 dOWn 4 Dirt or chips in hydraulic tappets 4 Clean tappets condition caused by 5 Excessive tappet leak down 5 Replace valve tappet Va Ve Sm ng prgwufg 6 Tappet face worn 6 Replace tappet check correspond jyigjj M 79 mg cam lobe is ww pp 7 Broken or cocked valve springs 7 Properly seat cocked springs replace broken springs 8 Stem to guide clearance excessive 8 Check stem to guide clearance repair as necessary 9 Valve bent 9 Replace valve 10 Loose rocker arms 10 Tighten bolts to specified torque 11 Valve seat runout excessive 11 Regrind valve seat valves 12 Worn rocker arm pivot s 12 Replace rocker arm pivot s 13 Push rod rubbing or contacting 13 Remove cylinder head and cylinder head remove obstruction in head

Next

Next