Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

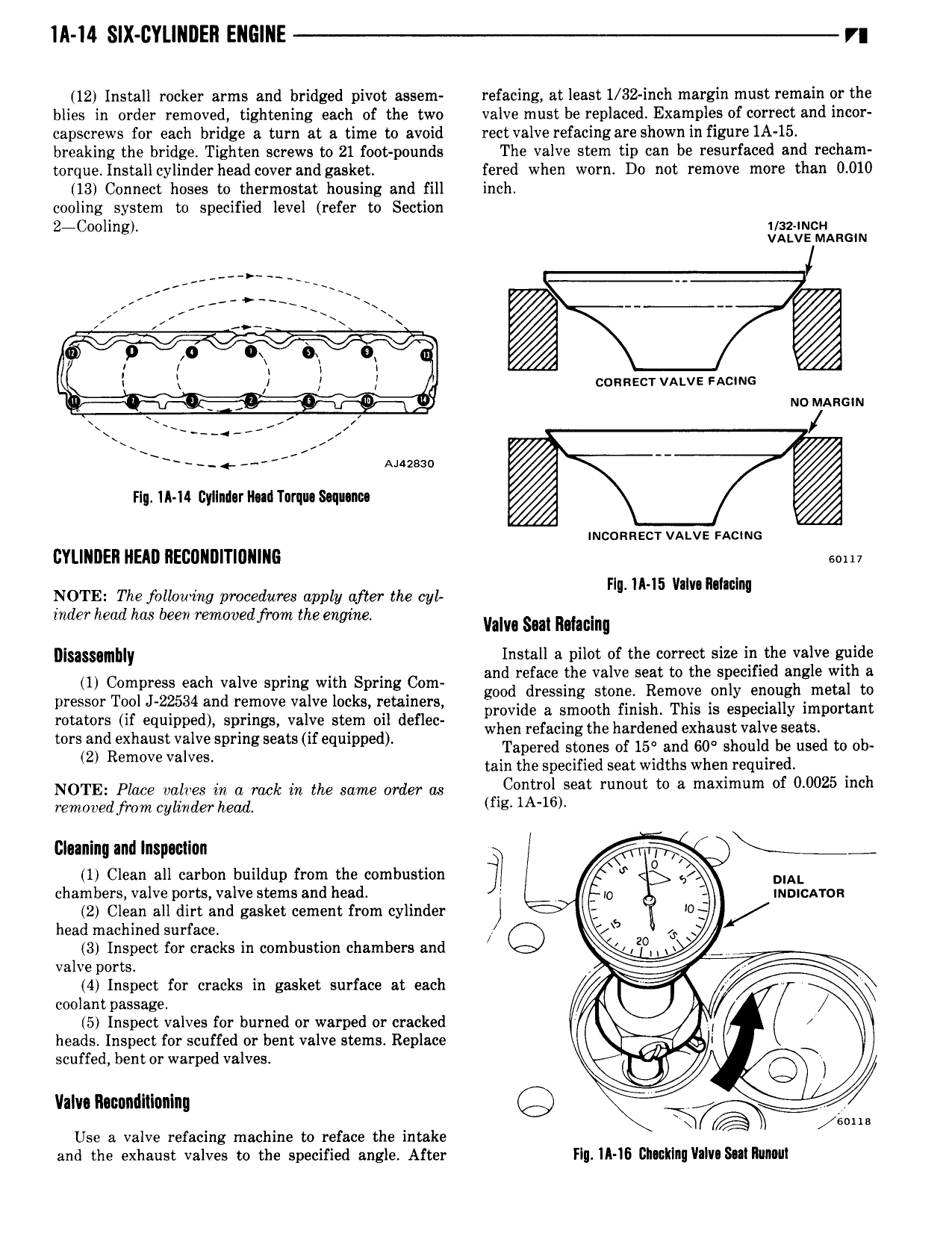

III I4 SIX CYLINDEII ENGINE VI 12 Install rocker arms and bridged pivot assem refacing at least 1 32 inch margin must remain or the blies in order removed tightening each of the two valve must be replaced Examples of correct and incor capscrews for each bridge a turn at a time to avoid rect valve refacing are shown in figure IA 15 breaking the bridge Tighten screws to 21 foot pounds The valve stem tip can be resurfaced and recham torque Install cylinder head cover and gasket fered when worn D0 not remove more than 0 010 13 Connect hoses to thermostat housing and fill inch cooling system to specified level refer to Section 2 Cooling 1 i2 mci l vAi vz Mancini 2 s V 7 T arrr T r 2 0 I U P K l l I ll J cuneecr varvs nemo x r 7 2 G Fly lA 14 Gyllmlar llnd T0rqu S q nl A A incuenecr vatve sacmc CYLINDER HEAD IIEGDNDITIDNIII6 sm 17 IVOTE The following procedures apply qfter the cyl Hmu 15 VIM www mder head has been removed from the cngme va S amd ljigggggmhly Install a pilot of the corre size tge valve guide 0 COMM mh vm Sim WM S l m Z d Si2 Z lEZ Si 2 i u Z ZZ l Q prgggc Tegl J 2 534d d crm Vqlve l g g g provide l smooth finish This is especially important m Org lh Eqmpp sRrmgs V8 y stem 3 e ec when refacing the hardened exhaust valve seats mrigll R ng V Spring Seatsu eqmppe Tapered stones of 15 and 60 should be used to ob tain the specified seat widths when required NOTE phwe Wires in 0 rack in the Same Order as Control seat runout to a maximum of 0 0025 inch renzvzvedfrom cylinder head fig 1 16 Cleaning and Inspmion I 1 Clean all carbon buildup from the combustion j O 5 DIAL chambers valve ports valve stems and head 0 Z mnncaron 2 Clean all dirt and gasket cement from cylinder J t 0 head machined surface Q 6 6 xc 3 Inspect for cracks in combustion chambers and 4 valve ports 4 Inspect for cracks in gasket surface at each coolant passage i l 5 Inspect valves for burned or warped or cracked heads Inspect for scuffed or bent valve stems Replace Y I Q7 scuffed bent or warped valves U V l Valvn llacnnlllllnnlnn Q X f Use a valve refacing machine to reface the intake and the exhaust valves to the specified angle After FI lA I6 Dlllcllllll llllv S tlII1 nMlI

Next

Next