Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

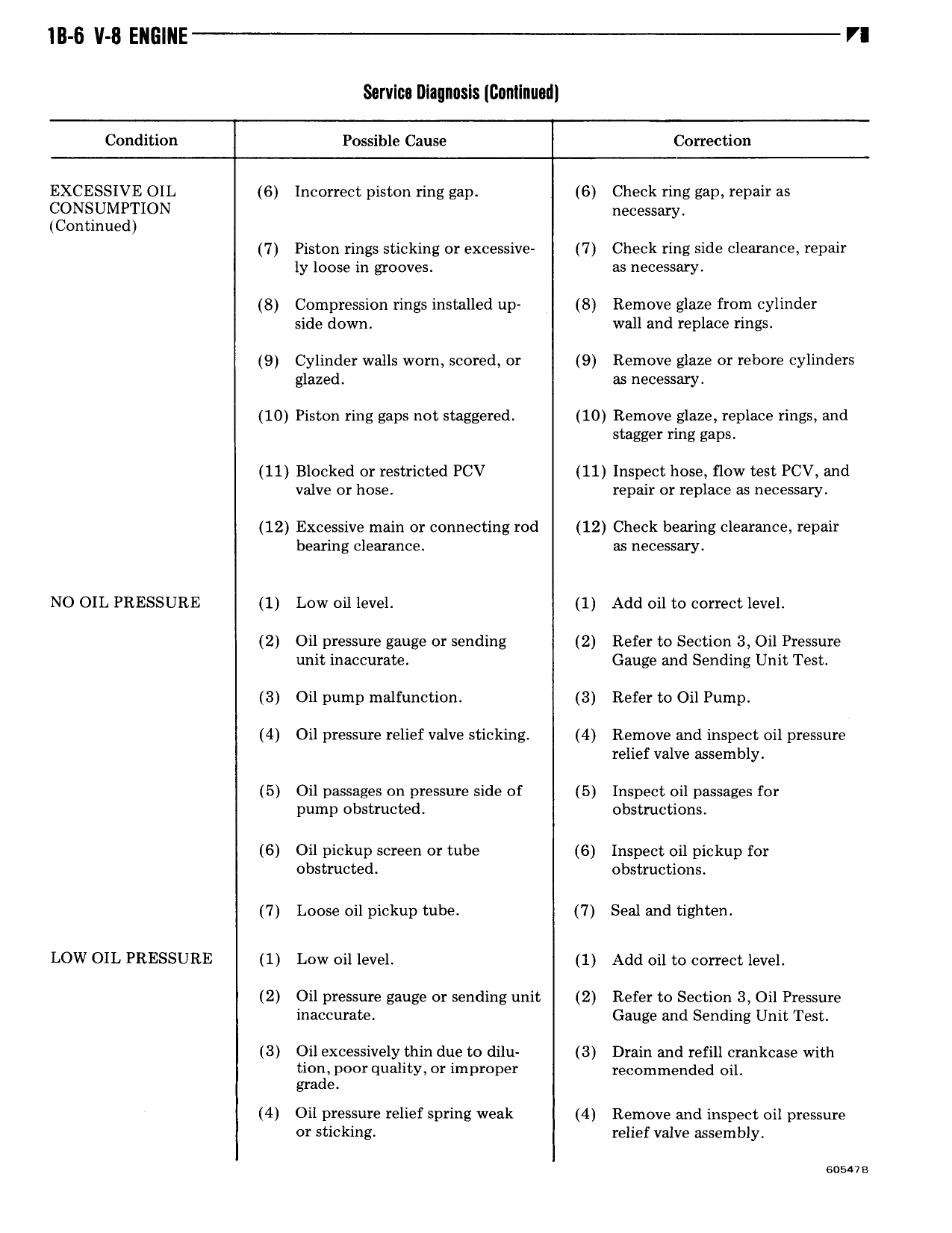

lll 6 V 8 EllGIllE VI Sorvlcn Illaqnusls continual Condition Possible Cause Correction EXCESSIVE OIL 6 Incorrect piston ring gap 6 Check ring gap repair as CONSUMPTION necessary Continued 7 Piston rings sticking or excessive 7 Check ring side clearance repair ly loose in grooves as necessary 8 Compression rings installed up 8 Remove glaze from cylinder side down wall and replace rings 9 Cylinder walls wom scored or 9 Remove glaze or rebore cylinders glazed as necessary 10 Piston ring gaps not staggered 10 Remove glaze replace rings and stagger ring gaps 11 Blocked or restricted PCV 11 Inspect hose flow test PCV and valve or hose repair or replace as necessary 12 Excessive main or connecting rod 12 Check bearing clearance repair bearing clearance as necessary NO OIL PRESSURE 1 Low oil level 1 Add oil to correct level 2 Oil pressure gauge or sending 2 Refer to Section 3 Oil Pressure unit inaccurate Gauge and Sending Unit Test 3 Oi l pump malfunction 3 Refer to Oil Pump 4 Oil pressure relief valve sticking 4 Remove and inspect oil pressure relief valve assembly 5 Oil passages on pressure side of 5 Inspect oil passages for pump obstructed obstructions 6 Oil pickup screen or tube 6 Inspect oil pickup for obstructed obstructions 7 Loose oil pickup tube 7 Seal and tighten LOW OIL PRESSURE 1 Low oil level 1 Add oil to correct level 2 Oil pressure gauge or sending unit 2 Refer to Section 3 Oil Pressure inaccurate Gauge and Sending Unit Test 3 Oil excessively thin due to dilu 3 Drain and refill crankcase with tion poor quality or improper recommended oil grade 4 Oil pressure relief spring weak 4 Remove and inspect oil pressure or sticking relief valve assembly

Next

Next