Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

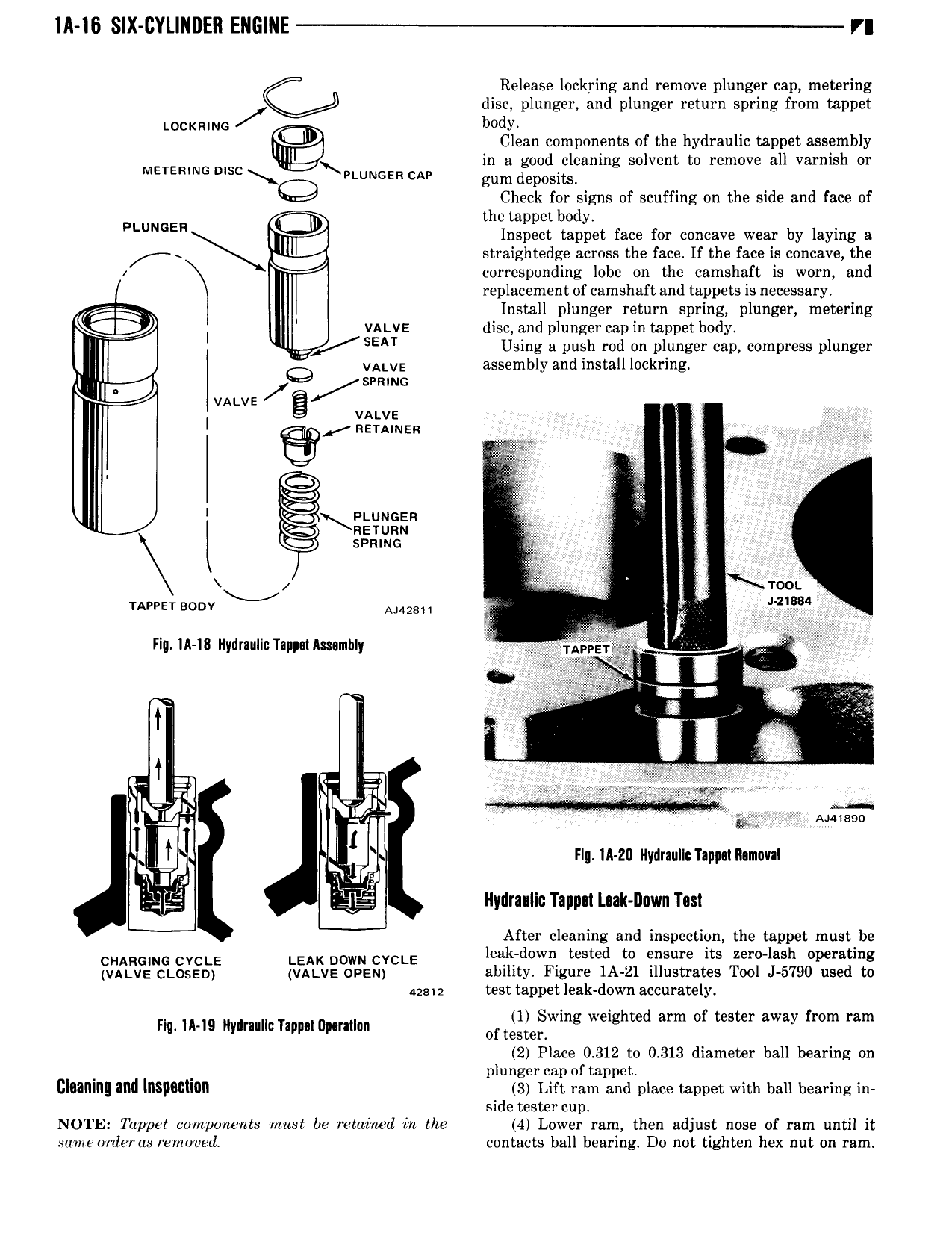

IA 16 SIX CYLINDER ENGINE VI Release lockring and remove plunger cap metering disc plunger and plunger return spring from tappet Locxnnuc b0dy Clean components of the hydraulic tappet assembly n go d cleaning solvent to remove all varnish or maremwo msc LUNGER EAP gmfx desosiw Q Check for signs of scuffing on the side and face of the tappet body PLUNGER Inspect tappet face for concave wear by laying a Q Stmighmdge across the face If the face is concave the corresponding lobe on the camshaft is worn and replacement of camshaft and tappets is necessary 2 Install plunger return spring plunger metering I VALVE disc and plunger cap in tappet body 7 V SEAT Using a push rod on plunger cap compress plunger Q VALVE assembly and install lockring senmc ud VALVE g vatvs i 2 I RETAINER l z PLUNGER K Y nerunu seems roor uwzr soov AJAQSH A 2 g wi c yiliiiii Flg IA tt ltynlrauIIcTapp tAsumhIy V V 1 App 1 pa Q M K Q i 1 J2 lr El 7 M Q g i Z v kjh Ii g BM VA AM J l Fig lA 20 ltyntraullutappat Ikmuval Fl on gig ltytlraullc Tappat Laak Down Test After cleaning and inspection the tappet must be leak down tested to ensure its zero lash operating wu cvcce vHAALRvGdN L d i E lysinrvg open ability Figure 1A 21 illustrates Tool J 5790 used to azsu test tappet leak down accurately 1 Swing weighted arm of tester away from ram Flp lA 19 ltydraullc Tappstttpantmn Oftesml 2 Place 0 312 to 0 313 diameter ball bearing on plunger cap of rapper GIOIIIIIIQ Iltll lII IWll II 3 Lift ram and place tappet with ball bearing in side tester cup NOTE Tappet components must be retained in the 4 Lower ram then adjust nose of ram until it srnnaervrderaa removed contacts ball bearing D0 not tighten hex nut on ram

Next

Next