Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

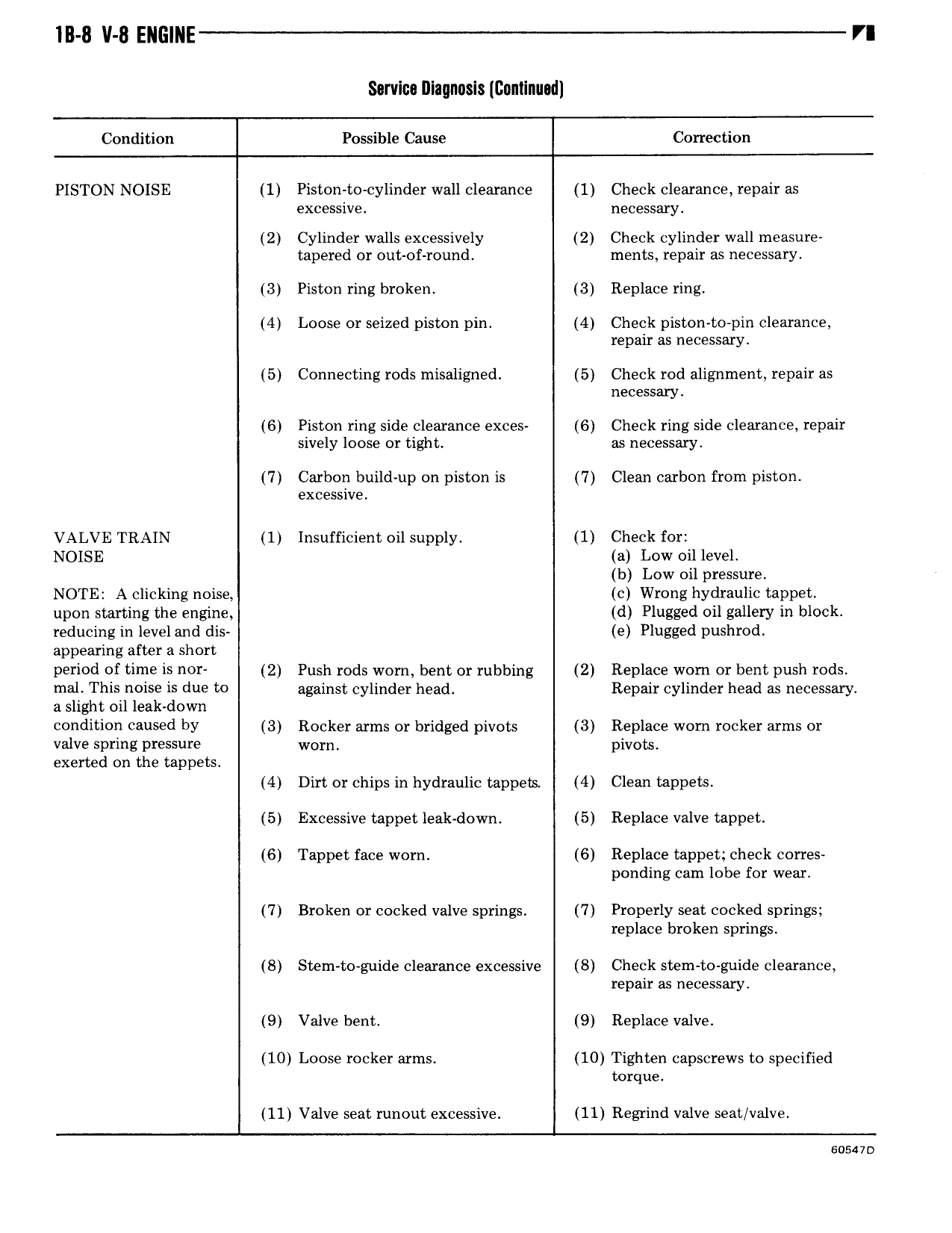

IB 8 V 8 ENG NE VI smlca Illagnasls Cnnunuad Condition Possible Cause Correction PISTON NOISE 1 Piston to cylinder wall clearance 1 Check clearance repair as excessive necessary 2 Cylinder walls excessively 2 Check cylinder wall measure tapered or out of round ments repair as necessary 3 Piston ring broken 3 Replace ring 4 Loose or seized piston pin 4 Check piston to pin clearance repair as necessary 5 Connecting rods misaligned 5 Check rod alignment repair as necessary 6 Piston ring side clearance exces 6 Check ring side clearance repair sively loose or tight as necessary 7 Carbon build up on piston is 7 Clean carbon from piston excessive VALVE TRAIN 1 Insufficient oil supply 1 Check for NOISE a Low oil level b Low oil pressure NOTE A clicking noise c Wrong hydraulic tappet upon starting the engine d Plugged oil gallery in block reducing in level and dis G Plugged pushrod appearing after a short period of time is nor 2 Push rods worn bent or rubbing 2 Replace wom or bent push rods mal This noise is due to against cylinder head Repair cylinder head as necessary a slight oil leak down condition caused by 3 Rocker arms or bridged pivots 3 Replace worn rocker arms or valve spring pressure worn pivots exerted on the tappets 4 Dirt or chips in hydraulic tappeis 4 Clean tappets 5 Excessive tappet leak down 5 Replace valve tappet 6 Tappet face worn 6 Replace tappet check corres ponding cam lobe for wear 7 Broken or cocked valve springs 7 Properly seat cocked springs replace broken springs 8 Stem to guide clearance excessive S Check stem to guide clearance repair as necessary 9 Valve bent 9 Replace valve 10 Loose rocker arms 10 Tighten capscrews to specified torque 11 Valve seat runout excessive 11 Regrind valve seat valve scsavo

Next

Next