Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

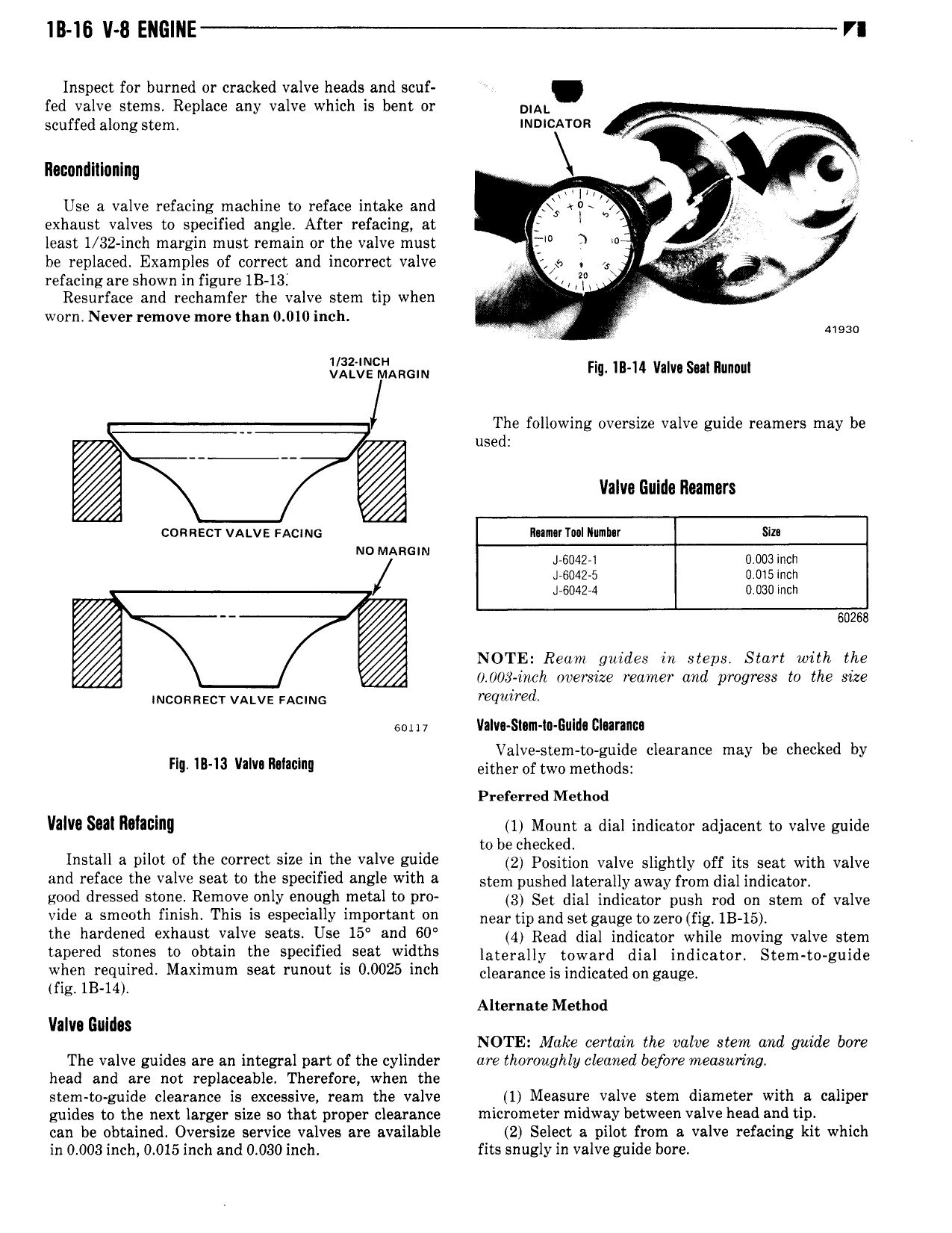

IB 16 V 8 ENG NE VI Inspect for burned or cracked valve heads and scuf fed valve stems Replace any valve which is bent or DIAL scuffed along stem INDICATOR M ll Ir ll Ilocunlllllnnlnll Use a valve refacing machine to reface intake and gs aT dg exhaust valves to specified angle After refacing at ld least 1 32 inch margin must remain or the valve must f 0 a be replaced Examples of correct and incorrect valve as a r a refacing are shown in figure 1B 13 V I M ff i Resurface and rechamfer the valve stem tip when l worn Never remove more than 0 010 inch y ARG N Fill in 14 vim sul nuttin The following oversize valve guide reamers may be V d 7 use Valva Guida Rumors A A connzcr VALVE Facluc I1 nllrTll II1wlI r NO MARGIN J 6042 1 0 003mch Je6042 5 0 015 man I 60424 0 020 mn 7 y am NOTE Ream guides in steps Sturt with the 1 003 inch oversize remner and progress to the size lucolmecv valve rsclmc QMil d sol iv Valva Sum l0 GuId Dlurancn Valve stem to guide clearance may be checked by Flu I I I lI I II I ll either of two methods Preferred Method Vllllll Sllil nlllElII 1 Mount a dial indicator adjacent to valve guide to be checked Install a pilot of the correct site inthe valve guide 2 Position valve slightly ost its atat with valve and reface the valve seat to the specified angle with a Stem pushed laterally away from dial lndlcalldra good d S 9d SWYIE R 0V 0 lY e g eh fneml 0 P 3 Set dial indicator push rod on stem of valve vide a smooth finish This ls especially important on near nn and Sel gauge r zerd l lg lg l5l the hardened exhaust valve seats Use 15 and 60 4 Read dla lndlcamr whlle mdylng yalya stem tapered stories to qbtairi the specified wit widths laterally toward dial indicator Stem to guide vghely egnired Maximum seat runout ls 0 0025 lnch cldarancaisindlcatad dnganga l lg Alternate Method Valva Eulllas NOTE Make certain the valve stent and guide bore The valve guides are an integral part of the cylinder are thoroughly cleaned before measuring head and are not replaceable Therefore when the stem to guide clearance is excessive ream the valve 1 Measure valve stem diameter with a caliper guides to the next larger size so that proper clearance micrometer midway between valve head and tip can be obtained Oversize service valves are available 2 Select a pilot from a valve refacing kit which in 0 003 inch 0 015 inch and 0 030 inch fits snugly in valve guide bore

Next

Next