Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

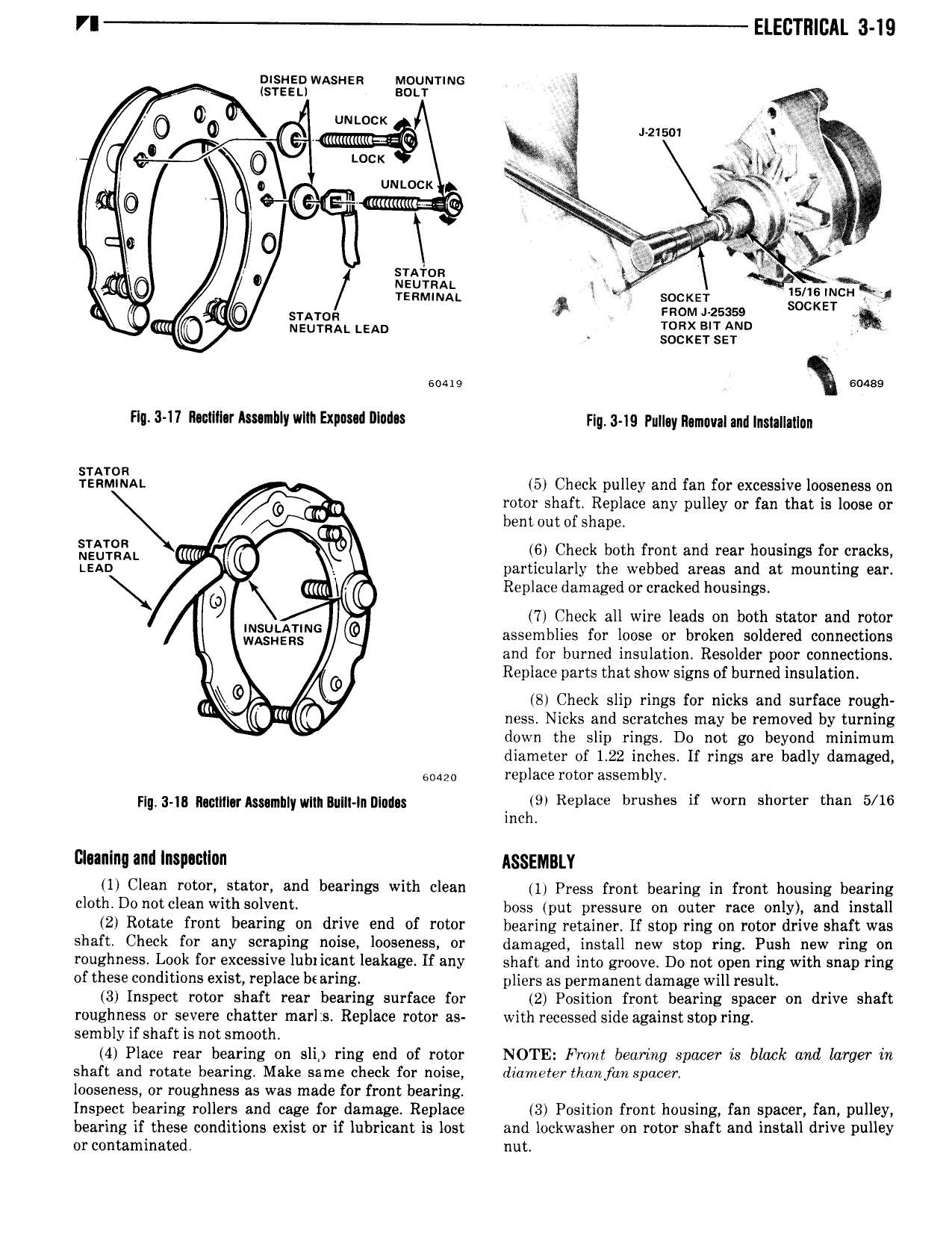

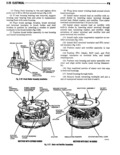

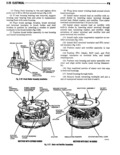

ELECTRICAL 3 19 msnzo wasuen moummcs srssu sou Y Q V 1 e 2 g I 5 J Loc Ml S Ii M g untocx as rw 9 i z V O 1 Y xw iiis 2 e An s M O Tsnmmm i socxzr gg STATOR rncvvn zszse CKEI e Home tm T eu socxsr ser wais V sues Flq 3 11 Ilaullllnr Asumhly wllh Expmd IIlnd s Flq 3 19 PuII y Ramuval and lnslallarlun igainirliat 5 Check pulley and fan for excessive looseness on rotor shaft Replace any pulley or fan that is loose or c lm bent out of shape L L wmv ii Check both front and rear housings for cracks LEAD particularly the webbed areas and at mounting ear gm Replace damaged or cracked housings 7 Check all wire leads on both stator and rotor w gN G assemblies for loose or broken soldered connections and for burned insulation Resolder poor connections Replace parts that show signs of burned insulation M a 8 Check slip rings for nicks and surface rough ness Nicks and scratches may be removed by turning down the slip rings Do not go beyond minimum diameter of 1 22 inches If rings are badly damaged sono replace rotor assembly ng a is amine Ammnnywnannulan nnnnuuaa J9 Replace brushes if wom shmer h 5 16 me Clcaninq and lnspacllnn A335 4 n y 1 Clean rotor stator and bearings with clean 1 Press front bearing in front housing bearing 0tl D0 0 0l 6 with SOIVBHL boss put pressure on outer race only and install 2 Rotate front bearing on drive end of rotor bearing retainer If stop ring on rotor drive shaft was shaft Check for any scraping noise looseness or damaged install new stop ring Push new ring on roughness Look for excessive lubricant leakage If any shaft and into groove Do not open ring with snap ring of these conditions exist replace be aring pliers as permanent damage will result 3 Inspect rotor shaft rear bearing surface for 2 Position front bearing spacer on drive shaft roughness or severe chatter marls Replace rotor as with recessed side against stop ring sembly if shaft is not smooth 4 Place rear bearing on sli ring end of rotor NOTE Front bearing spacer is blcwk and larger in shaft and rotate bearing Make same check for noise diameter thtmfun spacer looseness or roughness as was made for front bearing Inspect bearing rollers and cage for damage Replace 3 Position front housing fan spacer fan pulley bearing if these conditions exist or if lubricant is lost and lockwasher on rotor shaft and install drive pulley or contaminated nut

Next

Next