Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

1948791

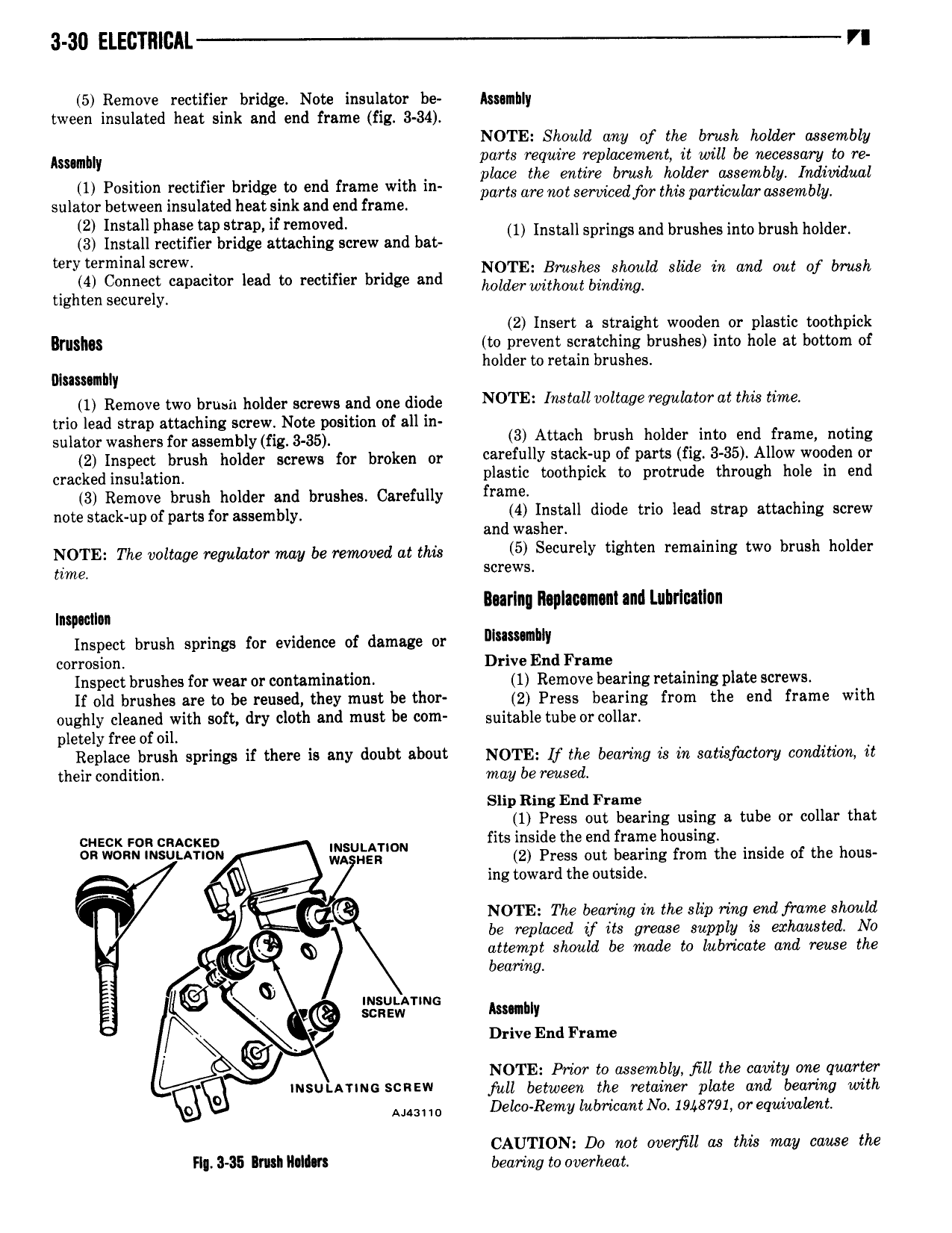

3 30 ElECTl lllIlL VI 5 Remove rectifier bridge Note insulator be Axacmhly tween insulated heat sink and end frame fig 3 34 NOTE Should any of the brush holder assembly Aswnms parts require replacement it will be necessary to re l h ti brus 1 Position rectifier bridge to end frame with in ix aieenoizgiwwfg L QjZ1 f 1 w L d l sulator between insulated heat sink and end frame 2 Install phase tap strap if removed I 3 Install rectifier bridge attaching screw and bat 1 natal Springs and brushes mm brush holder tery terminal screw NOTE 4 4 Connect capacitor lead to rectifier bridge and holdgr ld slide W and out of muh tighten securely 2 Insert a straight wooden or plastic toothpick BTIISMS to prevent scratching brushes into hole at bottom of holder to retain brushes mussamhly 1 Remove two bros holder sorows and out diode N0TE Install vvltwe rewwter at this time trio lead strap attaching screw Note position of all in suletm Washers for assembly gg 3 35 3 Attach brush holder into end frame noting 2 inspect brush holder screws for broken or cerefpllsi Stgfkjulg of o rts fg 3 35 A l1 1v qde 0 cracked insulation p as ic oo pic to pro ru e t roug o e in en 3 Remove brush holder and brushes Carefully frame e note seseleup 0 psrts for assembly d 4 Ilnstall diode trio lead strap attaching screw an was er NOTE The wmge remylatoy may be mmwd at my 5 Securely tighten remaining two brush holder ti e screws I ll ring lloplmmanl and Lubrltallon lnspscnn Inspect brush springs for evidence of damage or mm mY corrosion Drive End Frame Inspect brushes for wear or contamination 1 Remove bearing retaining plate screws If old brushes are to be reused they must be thor 2 Press bearing from the end frame with oughly cleaned with softe dry cloth and must he com suitable tube or collar pletely free of oil Replace brush springs if there is any doubt about NOTE lf the bearing is in satisfactory condition it their condition may be reused Slip Ring End Frame 1 Press out bearing using a tube or collar that euecx son CRACKED fits inside the end frame housing w s N iils ii glm 2 Press out bearing from the inside of the hous J ing toward the outside NOTE The bearing in the slip ring end frame should jfs be replaced U its grease supply is exhausted No Q attempt should be made to lubrwate and reuse the Q bearing y e L ibi M v Drive End Frame I NOTE Prior ta assembly fill the cavity one quarter INSULATWG SCREW fall between the retainer plate and bearing with Q Aus 0 Delco Remy lubricant N0 1948791 or equivalent CAUTION Do not aver ill as this may cause the H 3 5 Iml llllltn bearing to overheat

Next

Next