Ford Parts Wiki | GM Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Technical Service Manual January 1975 |

|

Prev

Next

Next

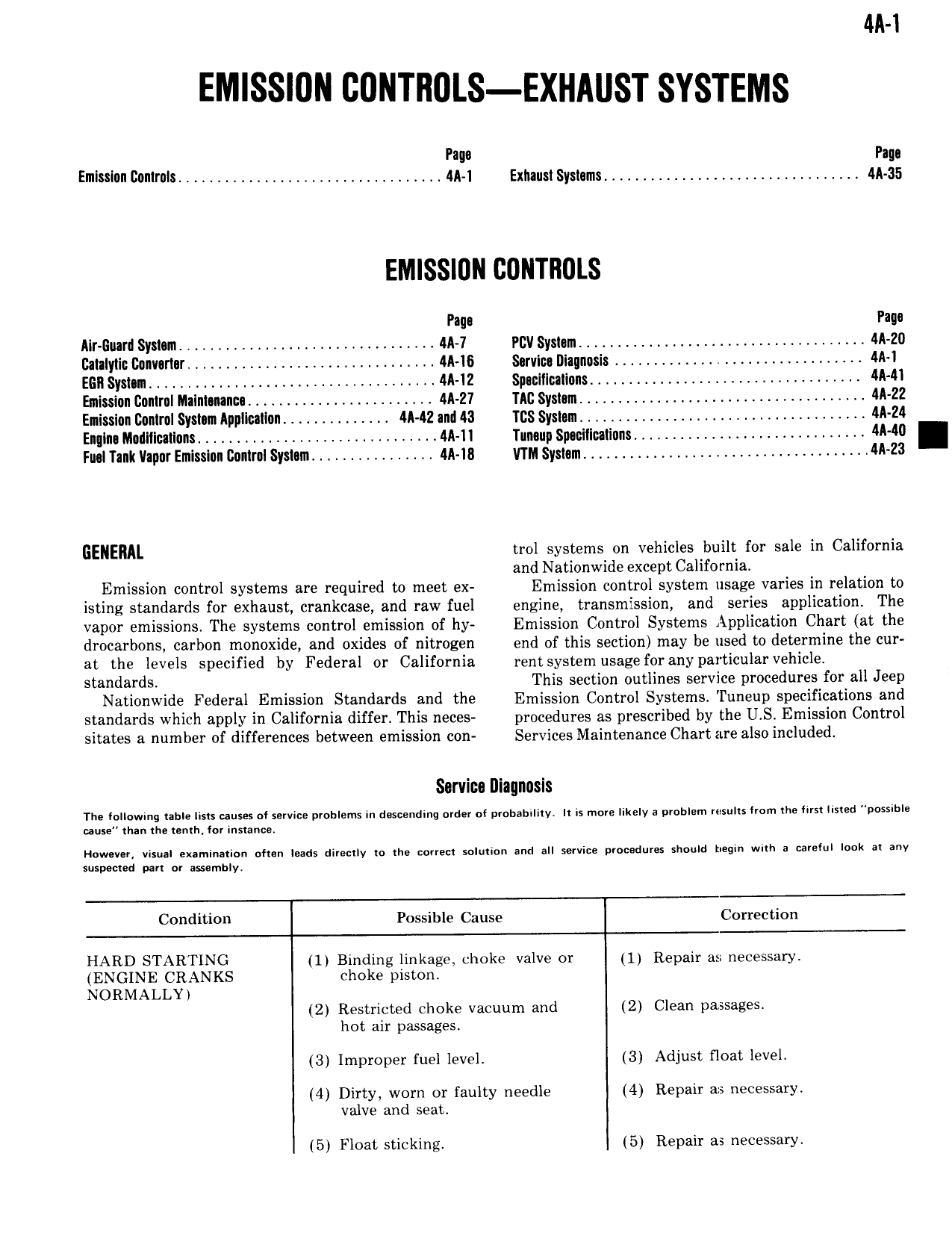

EMISSION CONT l0LS EXHAUST SYSTEMS Page Emission Controls 4A l Exhaust Systems 4 4 4 4 AA 35 Page Page AIr ttuarrl System 4 AA I PCV System 4 4 4 4 AA 20 Catalytic Convener 4 4 4 4 4 IA 16 Service Diagnosis 4 4 4 4 4 4 4 M4 E6lt System 4 4 4A 12 Speclllcations 4 4 IA At Emlssion Control Maintenance 4 4 4 4A 27 TAC System 4 4 4 4 4 4 M 22 Enisslon Control System Application 4 4 4 4 M42 and 43 TCS System 4 4 4 4 4 AA Z4 Engine Modtticetlona 44 4 4A tt Tuneup Specltlcetions 4 4 4A All Fuel Tentr Vapor Emission Control System AA ttl tltlll System 4 4 44 4 4 4 4 Mt Z3 GENERAL trol systems on vehicles built for sale in California and Nationwide except California Emission control systems are required to meet ex Emission control system usage varies in relation to isting standards for exhaust crankcase and raw fuel engine transmission and series application The vapor emissions The systems control emission of hy Emission Control Systems Application Chart at the drocarbons carbon monoxide and oxides of nitrogen end of this section may be used to determine the cur at the levels specified by Federal or California rent system usage for any particular vehicle standards This section outlines service procedures for all Jeep Nationwide Federal Emission Standards and the Emission Control Systems Tuneup specifications and standards which apply in California differ This neces procedures as prescribed by the U S Emission Control sitates a number of differences between emission con Services Maintenance Chart nre also included Service Diagnosis nrt rorrsmoo ttort rim mom ot mores otoortms m trmmortrrg order at otoosorrrty tr tt mare rrrtry at ptaorem msortt rmm too mst rtstea ootor r wow trotrt trtt remit rot rnstanca reowmt mom oitemmstrtm onto rmt orrtetry to tot totmm sorotttm ami an wom otoetaotet trtooro mgm with tr etrtror rtrort st any suspected out ar rstomsry Condition Possible Cause Correction HARD STARTING 1 Binding linkage choke valve or 1 Repair as necessary ENGINE CRANKS choke piston NORMALLY 2 Restricted choke vacuum and 2 Clean passages hot air passages 3 Improper fuel level 3 Adjust float level 4 Dirty worn or faulty needle 4 Repair as necessary valve and seat 5 Float sticking 5 Repair as necessary

Next

Next